Unfortunately, I didn’t have much time I could spent in the garage the last two weeks. But that doesn’t mean that there wasn’t any progress. After I fitted the new floorboards, I decided to have a stone-chip protection paint applied on the bottom side. The paint shop finished those as well as the inner wings just before I headed to a Classic car Rallye with the MGB GT in Bremerhaven last weekend.

Since I promised someone of the talkmorgan forum to measure the distance from the front CVH corner to the inner wing to see if dual Weber DCOE 40s would fit I quickly bolted down the inner wings. I could not find the cardbox mockup I made earlier when. I remember I made this 26,5 cm deep as this was the size, I got from the Burton Power website. The only correct way to fit a dual Weber DCOE 40 (or 45) would be to modify the inner- and outer wing as well as the hood. Nothing I am considering – the the Weber 32/34 DFT has been cleaned a while ago and will get some attention soon.

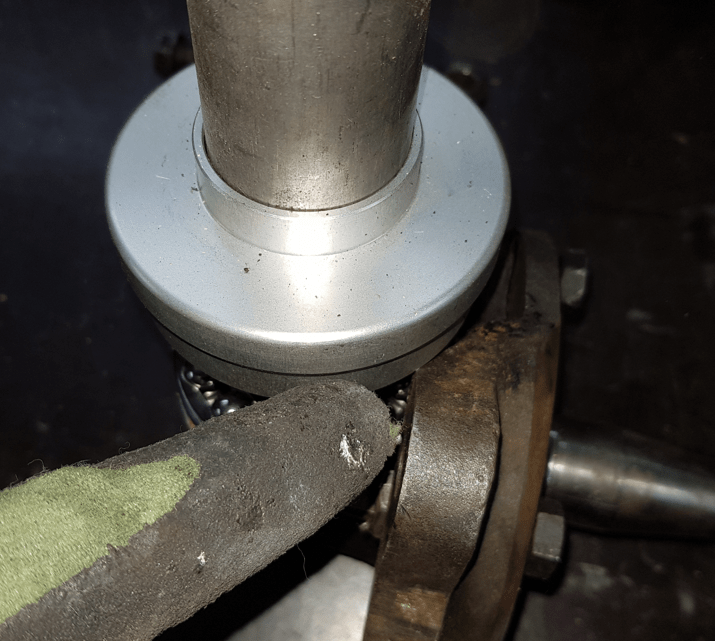

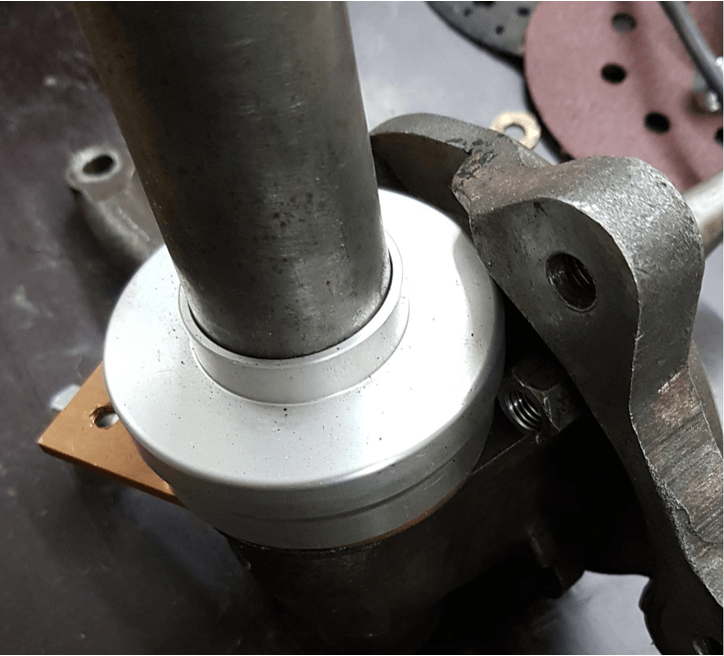

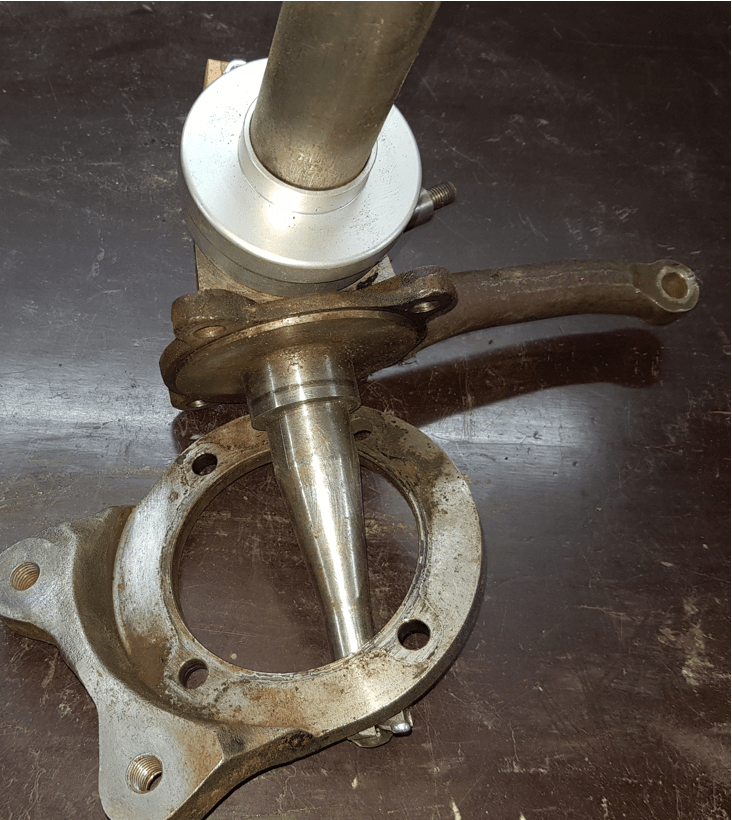

The master brake cylinder will get its own post soon – while I am waiting for a service kit I decided to do a test fit of the front suspension. Both the steering and the suspension were worn out and clearly not have been serviced well enough over the last couple of years. Getting new king pins, bronze bushes and springs was pretty much predecided. After a phone call with NewElms I ended up with King Pin overhaul kit. I guess I should add “kit C” 😉 – as well as negative camber plates, brake reaction bars and steering roller bearings. In other words: the only old part is the stub axle….

Now the issue I ran into while doing the test fit was the steering roller bearing. This only fits on my stub axle if I remove the brake caliper mounting bracket. Something I tried to avoid as I knew that the bolts are “secured in a distinct way” as the three dots on the end of the bolt clearly show. There are different views on if steering roller bearings make sense – especially on a Morgan 4/4. It will take a while until I can comment on this – for now I have them and therefore somewhat shorter springs and there is not turning back. The bolts are UNF with a hex head – not easy to get on a Friday afternoon in Germany – thankfully Tim from NewElms is so kind to send me a new set including nylocs via mail.

What initially wasn’t clear to me is that to fit the negative camber plates I must cut a piece out of the bottom crosshead. It becomes dead obvious when the negative camber plate is screwed onto the crosshead. I also understand now that Tim from NewElms is right about the track rod – it must be extended when using negative camber plates. I decided to ditch this plan for now.

Finally, I cleaned up some more parts. I have everything ready to install the new radiator. Well not. The inner wings need to be fitted first, which I am not going to do before the master brake cylinder is in. The bulkhead should follow – but it is easier to fit the heater, throttle, and some insulation first. I found the small leak in that the heater had in the upper right corner (by submerging the unit in water). Simon from SiFab has an easy sale I would say – I hope to get his new heater matrix next week.

Leave a comment