An aspect of a Morgan rebuild project that I did not really thought of too much in advance is trial fitting. Since this is still a hand-made car it is quite obvious that some parts require more fiddling when reassembling compared to for example the 1991 Mini Cooper I restored last year. So the last week has been a bit of back and forth with the bulkhead, frame, doors and panels. In addition I also made a super short term decision based on a requirement that my wife made which adds even more trial fitting – more on that later.

Now after I first attached the bulkhead to the chassis after it came back from the paint shop I decided to not install the toolbox on the right side anymore. This space needs to be reserved for a remote brake servo – which might be added to the car at a later stage. I should have thought of this earlier – before I had it painted, but you live and you learn. On top of the 6 screw holes for the toolbox about a dozen other small holes I overlooked at first where welded and the bulkhead repainted.

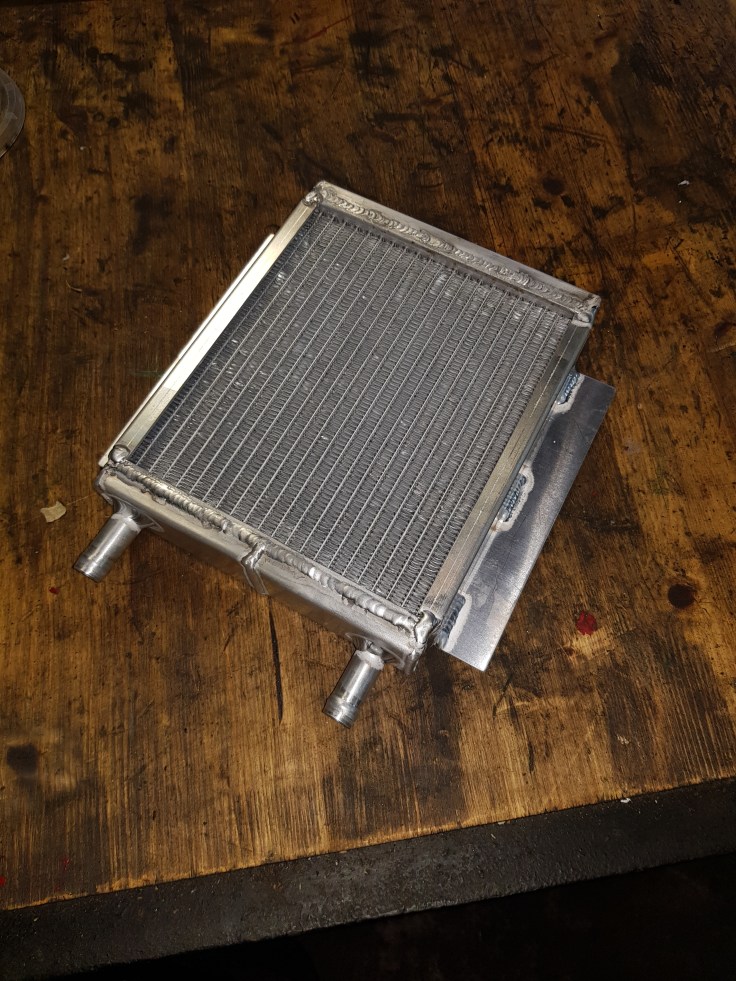

Fitting the new alloy heater matrix I got from SiFab and the ventbox I restored is easier anyway when the bulkhead is on the bench (well – floor…) This is a good example on why a hand-made car needs more trial fitting. While the dimensions of the new matrix are spot-on – the lower connector is touching the bulkhead. Back in the factory they solved this issue by soldering the connector in an angle to the matrix. This also made it impossible to remove the pipe without removing the entire matrix.

If you have a older 4/4 and order a nice alloy heater matrix from Simon – make sure to ask him to attach this connector differently.

I did not want to mess with the new heater. The alternative idea was to create an alloy spacer that will lift the entire unit. But unfortunately this would cause the heater cover to interfere with the hood. (Thank you Wolfgang for reminding me on this) So I ended up just lifting the front by using two 3mm thick alloy pieces. This created enough clearance to attach the new hoses for the heater. I still have a gap on the side – but even the old matrix wasn’t flush on the bulkhead. Some more alloy bar and Noico red 8mm should close the gap for good.

So what was my wife’s requirement for the car and who is Wolfgang? If you ever had a chance to compare a MGB GT with a Frontline LE50 you will notice the huge difference in terms of the suspension, steering, brakes – well yes – and power. Frankly I could not afford a LE50 (but still on my wishlist). Nevertheless, my MGB GT got some Frontline treatment. This included the Costello/Frontline suspension, a remote brake servo and power steering – which is a huge improvement from a usability point of view.

Turns out that Wolfgang Hüttner not only is the main contact for EZ Powersteering in Germany. He is also a fellow Morgan owner and was involved in the development (founder?) of EZ Powersteering. On top – he is also part of the section unMOGlich of the Morgan Club Deutschland and lives close by. We had a great call, I checked if I can fit the unit myself and ordered the PowerSteering. Wolfgang also helped me to get the invoice right away – I did the wire transfer and on two working days later the unit already arrived.

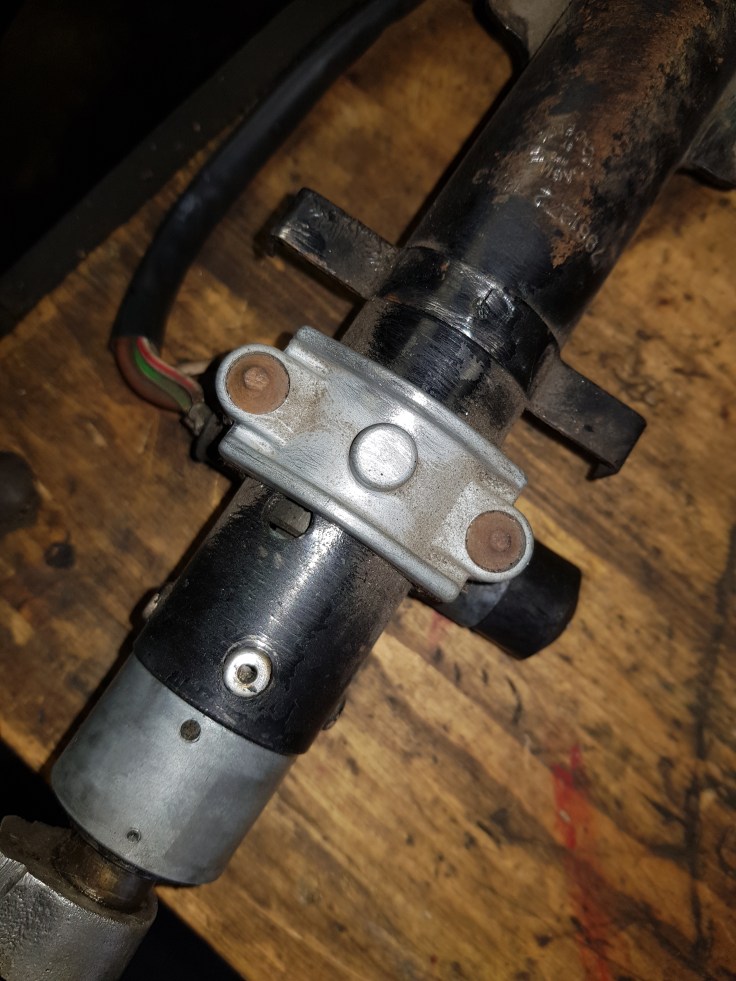

Since I wasn’t feeling well this week I only had a couple hours yesterday evening to do some test fitting. While the steering column is exactly the same, the Morgan +8 which was used for the picture documentation by EZ Powersteering has a different bulkhead compared to my 4/4 four-seater. The Ez Powersteering is screwed to the steering column bracket which needs to be shortened. On my car the bracket has to be cut off almost completely and the two bolts from the top need to be drilled through the bulkhead itself. The bracket also interfered with the new under scuttle roll-bar from NewElms anyway.

With heater and accelerator pedal fitted to the bulkhead the next test assembly was done. Good news is that it will fit – but the powersteering motor will cover on off the vent pipes that go to the screen. I need to come up with a solution for this…

Next up is reapplying a new coat of paint to the frame. you can see on the pictures that the “black” wood paint has a brown touch. I will also pick up my overhauled rear axle from JB Sport and some spares from Melvyn Rutter next monday. I really hope to attach the bulkhead and frame for good in the next 10 days.

Starting point

New heater matrix from SiFab

Noico red 8mm ontop of heater

new heater touching the bulkdhead

The way this was solved at the factory in 1984….

using two 3mm think alloy pieces to raise the front of the heater matrx… still thinking on how to close the side gap…

Under scuttle rollbar

rollbar touching steering column mounting bracket

old steering column

Thank you Wolfgang for the quick Dremel action

Bulkhead with heater, the roll bar and powersteering…. tight fit

EZ Powersteering in 4/4 fourseater. The motor is too close to fit the

Bulkhead with heater back on the car – ready to be taken off again 🙂

Leave a comment