The day started very early and clearly not as expected. My daughter called just after 6am because her Ford StreetKa was making “strange noises” on her way to work. Since I don’t really need a car during these forced 100% home-office times I quickly drove to the point were she decided that it is better to shut down the engine and we swapped cars. I really wonder how she managed to get that far on 2 cylinders – a marten bit two ignition wires. With the help of the German ADAC I was back home shortly after 8am for breakfast.

After work I could finally pickup the bonnet, wings and cowl that I brought to RTEC in Andernach for paint stripping. I am really glad that I made the decision not to do this myself. The bare metal looks like it has just been made moments ago in the factory. There were just minimal areas with old filler. There is no significant rust damage anywhere and by tomorrow everything will be covered with EP primer.

Since IOZ is just a few miles from RTEC I also picked up a new Facet fuel pump and a fuel pressure regulator/filter – the same as I have in the MGB. While talking to one of the staff-members at IOZ about the potential cost for the repair of my Weber 32/34 DFT, I made the decision to no have this done there. BurtonPower offers a new Weber 32/34 DMTL for half of the cost. Sure – I will loose the AutoChoke (which unfortunately is one of the few spare parts I already bought for the DFT…) – but as Andre Koopmann said: No AutoChoke means one thing less that can fail… valid point.

With the Rutherford challenge that started yesterday in my mind I wanted to get into the garage early – but the weather was just too nice. So I took a detour and the 900 meter to my garage translated into ~50km on the clock in my MGB GT. This reminded me that I naming this blog “FixingC6622” – was maybe a bit too limiting. At least I felt I have to post a picture of “Maggie” today.

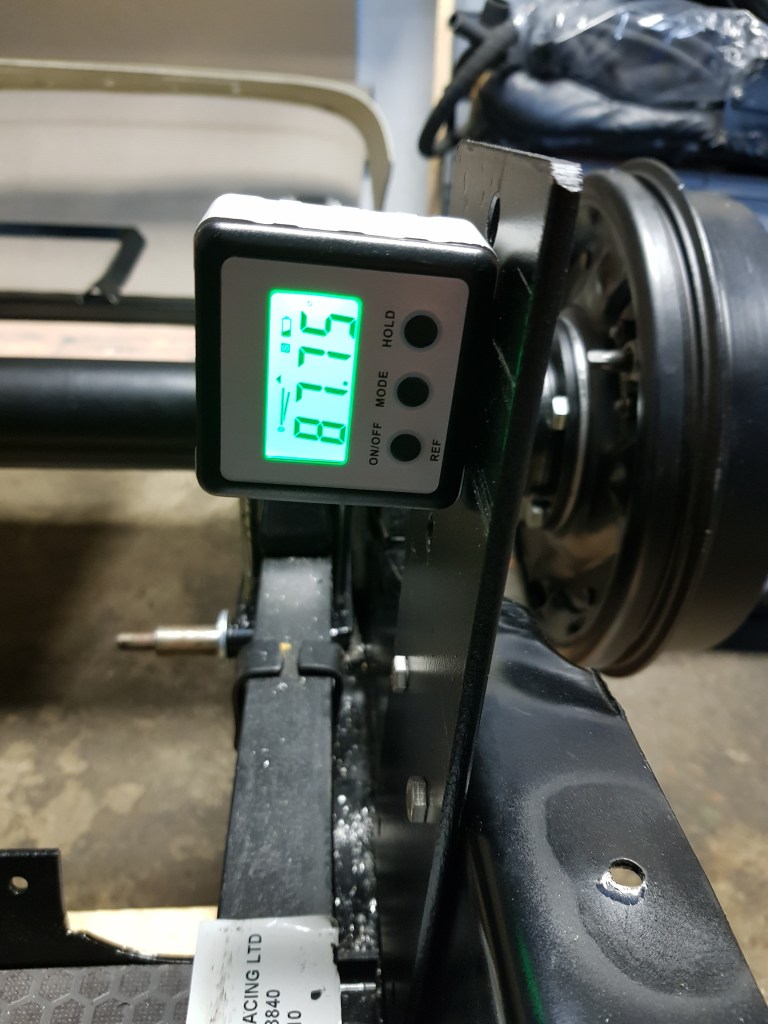

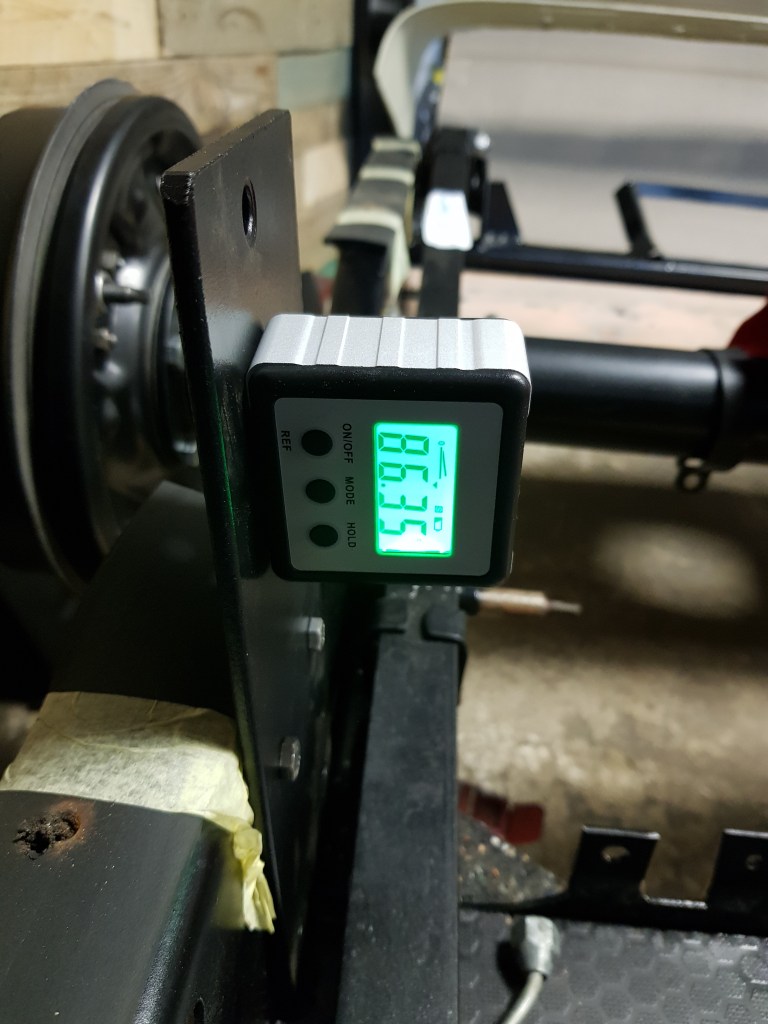

Based on a comment in the TalkMorgan forum from TBM I continued to work on the rear suspension after my little tour. Equipped with the bevel box I use on my table saw I started to check the chassis. Cutting a long story short: the sides of the chassis in the area around the rear axle are not perpendicular to the chassis bottom. The lean outward by about 3 degrees.

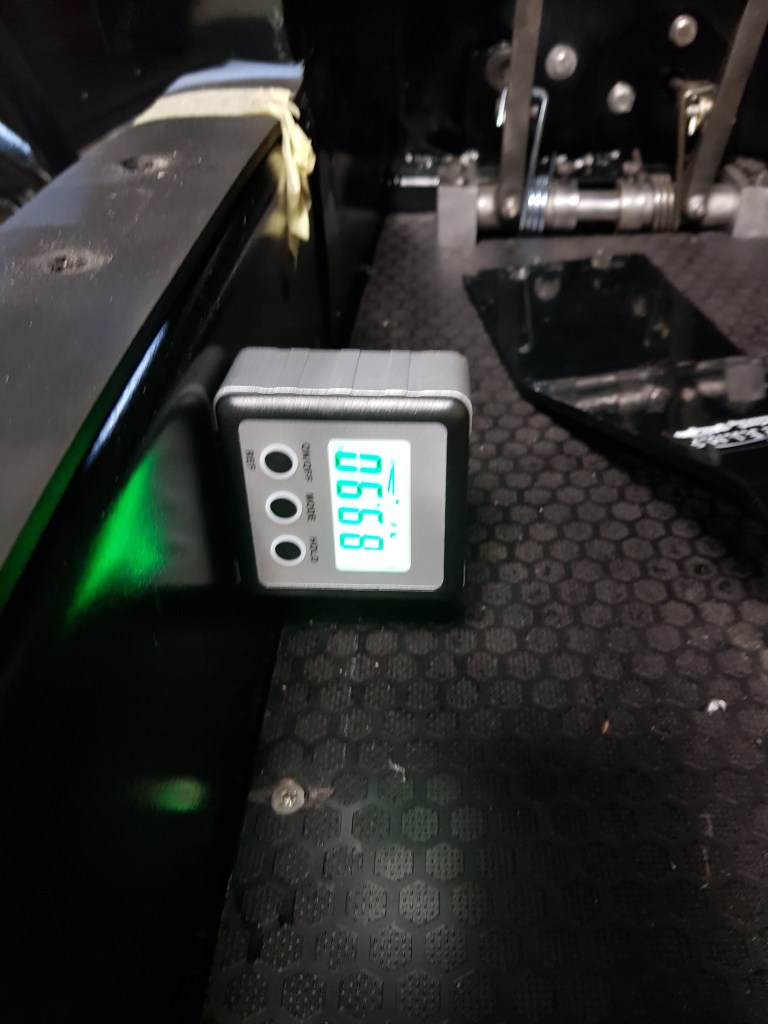

In order to test this I created a couple wedge shaped spacers out of plywood on my table saw. This was cut with a 87degree angle to compensate the angle of the chassis. The thicker one I created move the bracket too close to the leaf spring. With the other spacer I checked that the lower part of the bracket now sits in an almost 90 degree angle to the chassis. This is where I noticed that brackets are also part of the problem. The shock mount point is also not perpendicular to the side of the bracket. It is off by ~2 degree.

I finished the evening by taking the rear axle out again. For one this is necessary to fit the brackets (once I figure out where to get an alloy block spacer that I require now). It will also be much easier to fit the Panhard rod tomorrow as I can drill from the top. And last but not least I will be able to check the center pin location of the leaf springs..

Marten bit…

There was quite a bit of old filler here

if you look close you can see the multiple parts that are welded together for a front wing

The idea just put clear coat on the bonnet crossed my mind…

Maggie

new fuel pump and filter… Weber still needs work

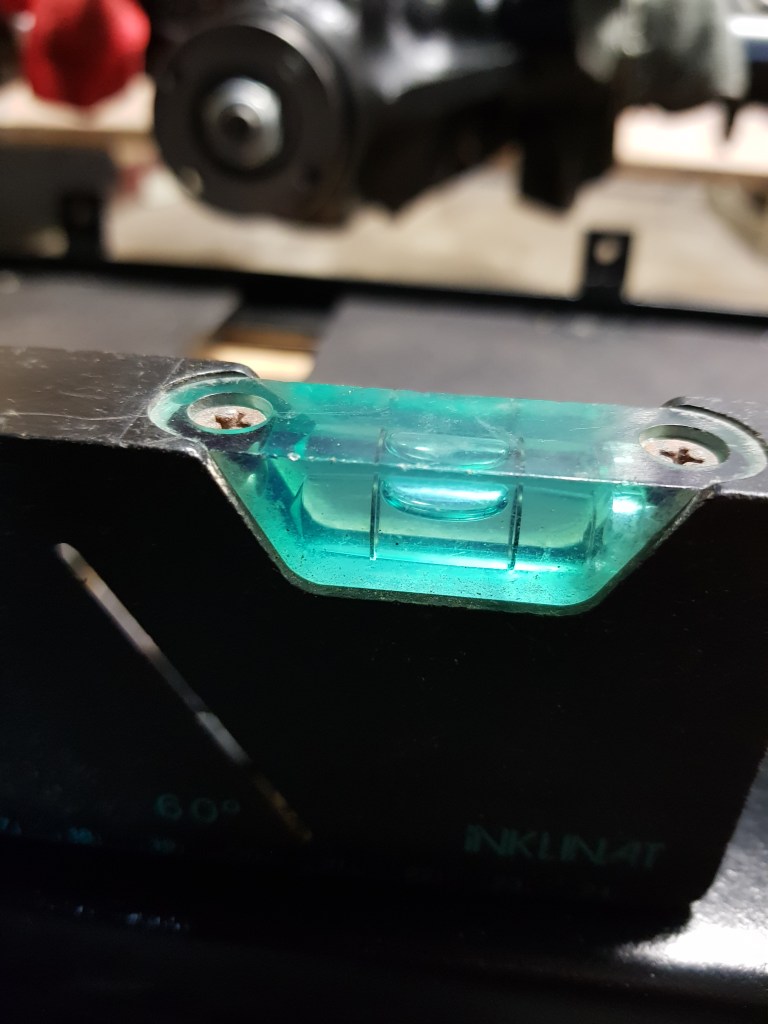

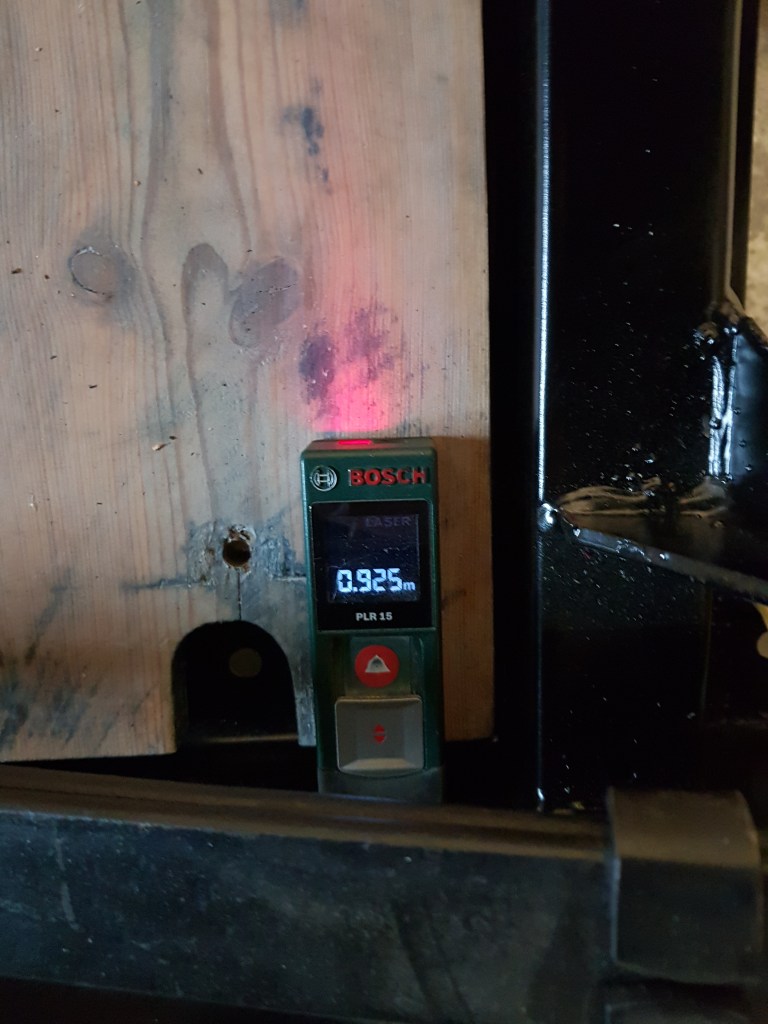

The chassis is leveled

The chassis is leveled

nearside around the place of the damper bracket

the other side ist also not 90 degrees

Everything on front of the crossmembers looks good

the chassis as a consistent width

A test with alloy spacers.

plywood wedge with 87degree cut

with this spacer I get the brackets are perpendicular to the chassis bottom

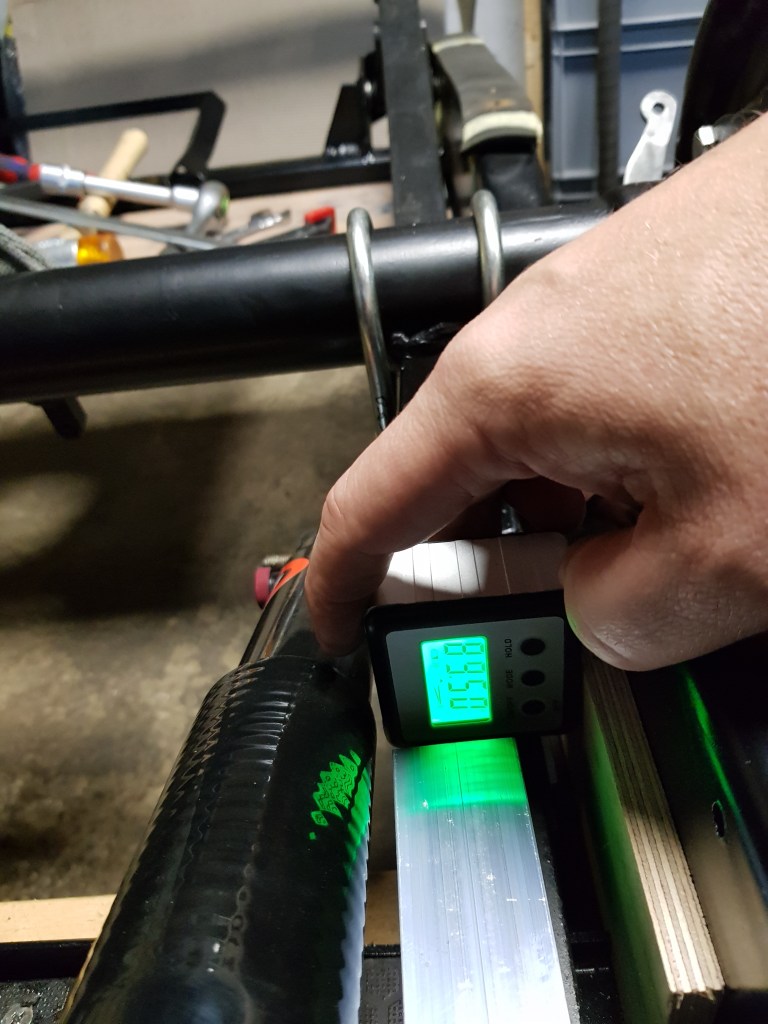

even with the wedge the bracket is still 2 degrees off

Slowly releasing the pressure of the leaf springs

Not too difficult to get the axle out this time…

I will check the leaf springs tomorrow

Leave a comment