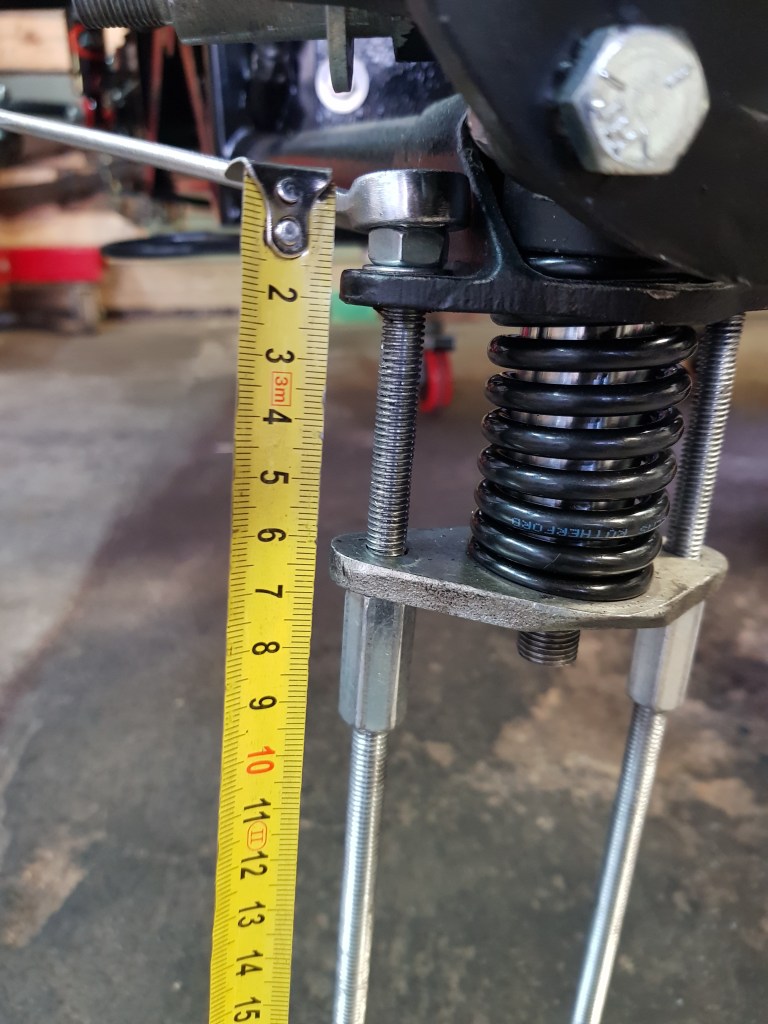

Getting to a rolling chassis was my main priority for this weekend. As I already wrote in an earlier post I forgot to put the bumpstops (basically two cut-offs from a rubber hose) around the kingpins. Using the “Tried & True method” for the 3rd time now – I only need about 45min for removing and refitting the entire suspension on one side of the car. I am using M8 threaded rod. Since I also used these to push in new bushes into Mini’s rear suspension they are a bit longer – as you can see you would be fine with two 12mm M8 bolts. Make sure to use a long nut beneath the bottom plate – this makes the task easier.

After cleaning the hubs I fitted the brake disc. I am a bit worried about the wheel bearings in the front hubs. I just fitted the castle nut a bit more than hand-tight since I am not sure about the correct torque setting (210nm I assume). But with a little pressure the wheels don’t turn very well. Next up were the new HiSpec billet 4 brake calipers. It is a tight fit with the main spring – but with some wiggling for the main spring both bolts fot the calipers went in. The new brake discs are not completely centered in the billet 4 calipers yet. I have a 2mm differen – so I need a 1mm shim between the caliper and the stub axle.

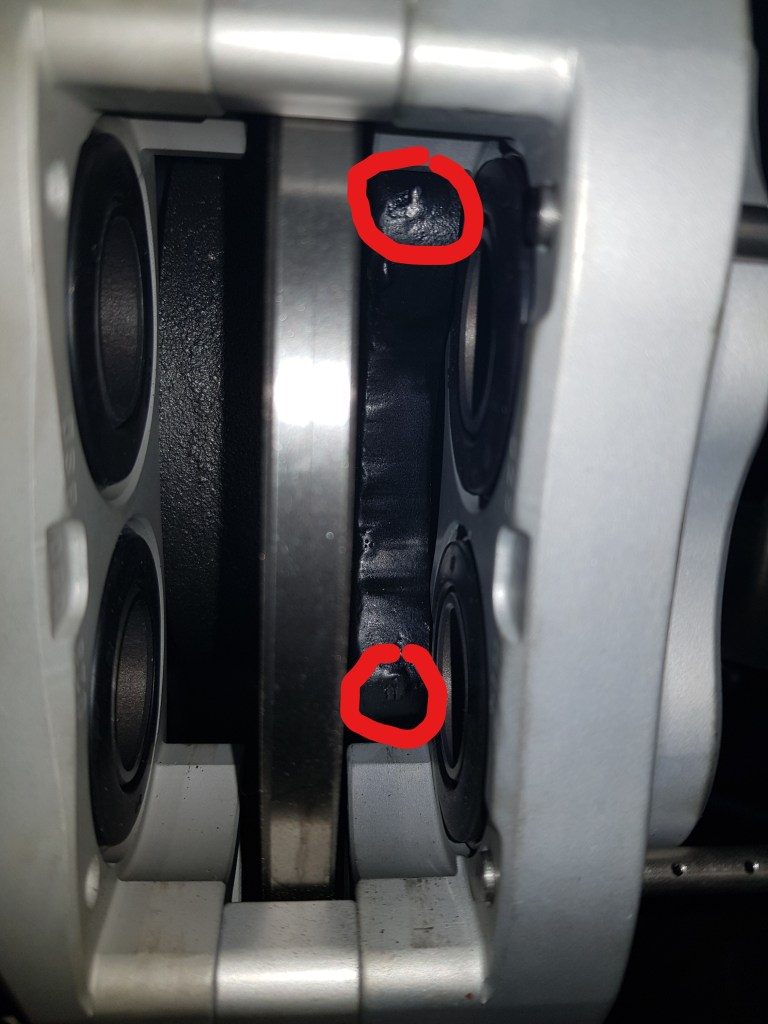

This was all too easy. A typical wrenching weekend without issues and problems would be boring, right? Well – the problem followed immediately when I tried to add the brake pads. The front one fits without a problem, but the rear one slightly to high with it’s 60mm. They touch the stub axle and there is 1mm missing to fit the pin’s that hold them. I need to ask Tim Ayres who sold me the brakes if the pads could be wrong. Finding pad that are just max 57mm high would be the easiest solution. I theoretical alternative way could be to file off 2-3 mm from the stub-axle. For a number of reason I think this would be a bad idea…. but I need a solution.

Since I am also missing a flex brake hose for the rear axle I could not fill the brake system and bleed it. I put the front tires on anyway to see how the new calipers will fit. There is plenty of room – so nothing to worry about. So – I got the rolling chassis – but the lack of brakes makes it unstoppable. The wiring loom is still not ready at AutoSparks.co.uk – one of the larger open tasks on my list. This means I will focus on frame and panels for the next couple days. I already invested a few hours this weekned -Details will follow on another post later this week.

rolling .. but no brakes…

Replace the front bolt with threaded rod

once both rods are in you can use a

Careful at this point – the main spring is still compressed (roughly 4cm). I use a piece of wood to press it down and get it out.

the pin that secures the brake pads cannot slide it – the pads hit the stub axle and there is at least 1mm missing

I will add a 1mm shim to center the discs

right fit – but all good

The brake pads left marks in the paint on the stub axle.

plenty of clearance towards the rims

Leave a comment