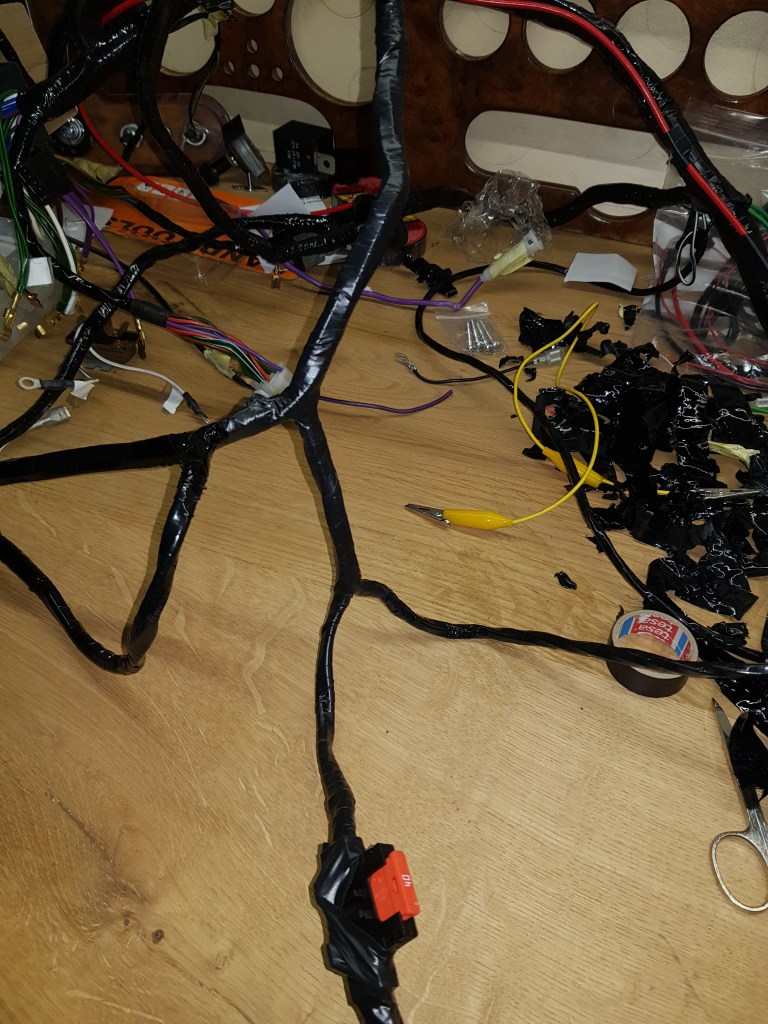

The only positive aspect of working on the new loom for the Morgan is the fact that I can do this in my office instead of freezing cold garage. As mentioned before there are a number of issues, I need to fix to make the new AutoSparks loom fit my 1984 Morgan 4/4. The first thing I addressed was the bad location of the fuse for the radiator fan. I am still annoyed that it is an inline fuse – but relocating this further away from the exhaust manifold was quite easy. It will be the only inline fuse and it is also a bladed one now. I know – the red 40amps fuse is overkill – it is the one I took from the power steering for now.

Next up were the four inline fuses for behind the dashboard. I didn’t like those and as the sidelamps would have been without one – the decision to to add a small, bladed version behind the dashboard was easy. After tracing and labeling all cables I removed the PVC, soldered extension cables to the existing ones and taped everything up again. I also prepared extensions for the new fuse holder I originally wanted to install on the bulkhead in the engine bay – just above if the location of the old one. Since I wanted to get exact required cable length, I took everything to the garage tonight.

Thinking that installing the reverse light switch into the Ford T9 was a simple warm-up task I took a 22mm wrench and….. killed the switch. Maybe the material was to cold (-2 C° when in the garage when I started…) maybe it was already broken – whatever. Fortunately, it didn’t break and still functions. I screwed in hand-tight, tested it with my wire tester and left it in the gearbox for now. After another quick trial fit of the loom, I put the power steering back as well as one demister funnel and hose (still waiting for the new one from Mogparts.net). While I was still playing around trying to figure out the best place for the fuse box and where I solder the cables – an email from Sweden came in. Stefan (a fellow Morgan owner with a nice 1987 Morgan 4/4) was so kind to send me a picture of his car and fuse box location. I was somewhat surprise to realize that it was under the dashboard.

I never wanted to go down this route and spend hours reading wiring diagrams and modifying a wiring loom. Obviously, I could have easily repaired the old loom by now. I could have even replaced the entire PVC wrap… but too late – I made up my mind – order another (16-way MTA) bladed fuse box and will also mount it behind the dashboard (just like in the 1987 Morgan) This way reduce the number of cables I need to solder together – as I will just reroute and shorting the existing one…. I sincerely hope that by the end of next week I am done with the everything-else-but-fun task.

the fun half of my desk – the other half is for work…

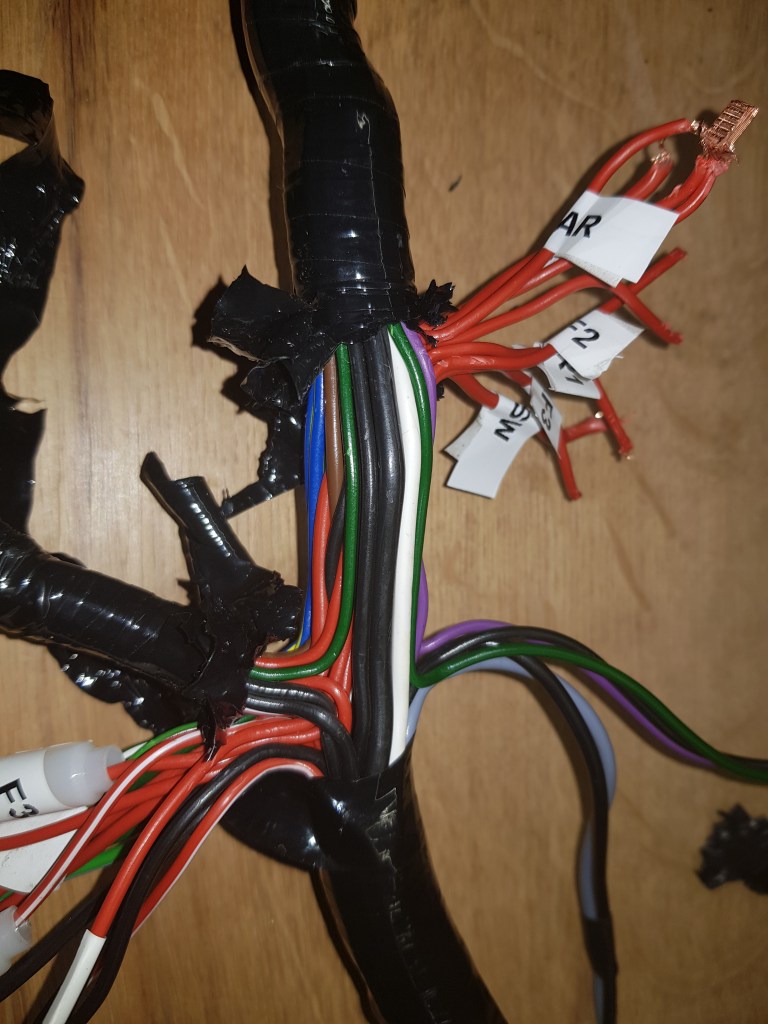

removing the PVC from the loom is messy

It is important to directy tape junctions back together

Small modification – but now the fuse sits further in the front of the innerwing. much better

tracing the red cables

..to get rid of all intine fuses

The new fusebox for lights

looks a bit cleaner

I killed the reverse light switch

barely visible – the 13way EconoSeal connector

prepared but now dismissed…

testing on where fusebox and cable should be mounted

Leave a comment