Admittingly, getting the Mini and Morgan back engines into running condition is not comparable to the Apollo mission. But while it might not be rocket science it sure was a learning curve for me. And interestingly enough – I made similar mistakes on both cars – or more specifically: the carburetors tuning and ignition timing. After the easter weekend I was able to collect the Mini engine as well as various spare parts this Tuesday. My plan was to finish the Mini by Thursday and get it back on the road. I need all the space I can get in the garage to prepare the Morgan for painting.

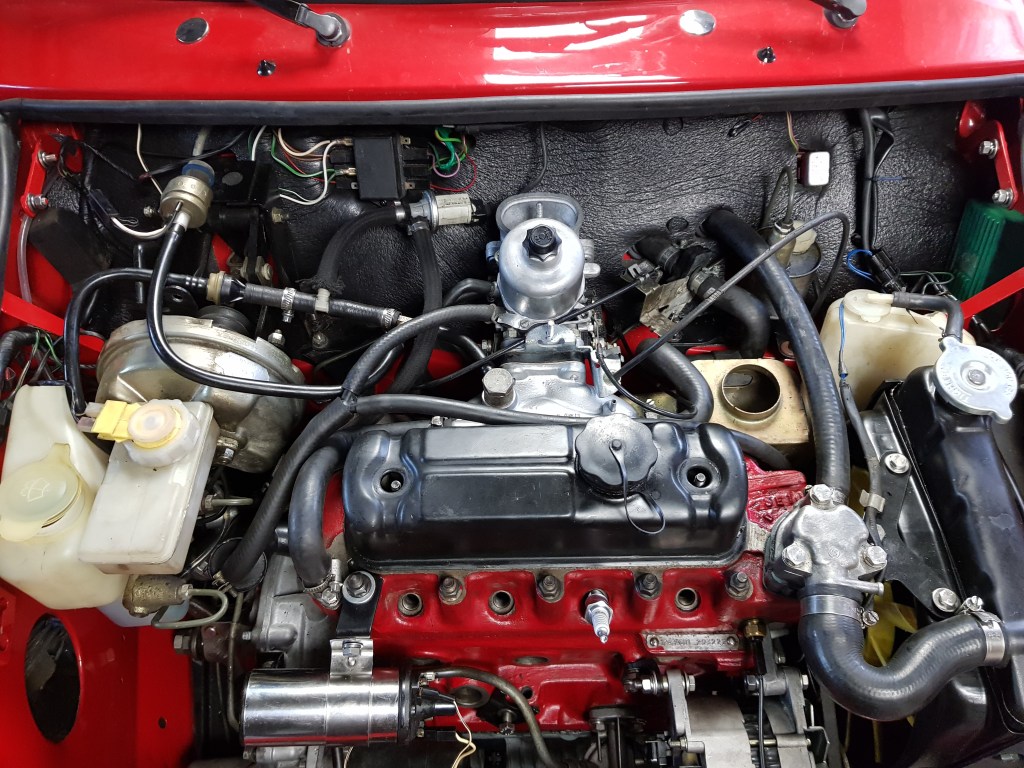

When taking out the engine all by myself scratched the paint in the engine bay. Thankfully, my oldest daughter helped getting it back into the Mini by lowering the engine hoist slowly while I maneuvered the engine around the master brake cylinder. After this quick success – many time-consuming and annoying setbacks followed. Getting the bolts and the engine mounts aligned took ages. If a washer, nut, or bolt can drop – they certainly will drop! And from the sound it makes you know that it doesn’t hit the floor – but instead it will be stuck between the subframe and some engine part.

It was the third time to get the engine out and back in again in 18 months of owning the Mini. I thought with experience it will become easier and quicker. And this was true for many tasks – but I really struggled putting back in some parts. The cast iron exhaust manifold to exhaust connection was one of the struggles. I was so tempted to fit an LCB (which I happen to have in spare…) but I will keep this Mini to its original specs at least until it get’s it historic license plate next year.

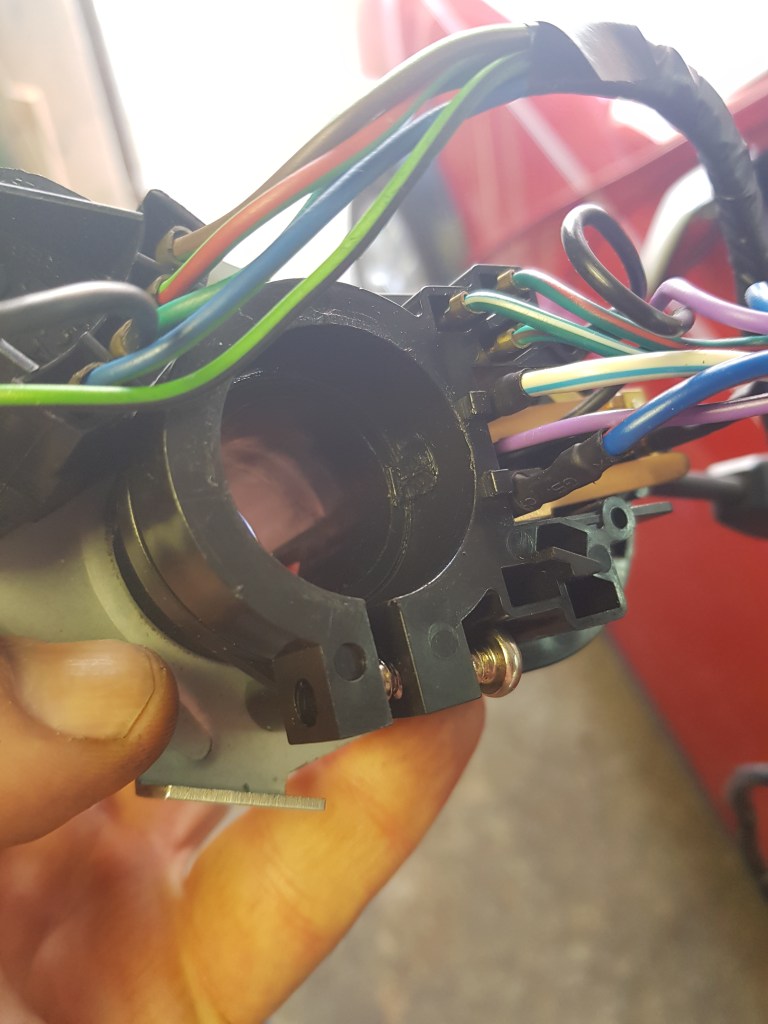

This really helpful and good video on Youtube: (4) Race Engine Build For Our Classic Clubman 1275 GT – Episode Four. – YouTube gave me some good inputs and certainly, next time it will smoother. It is just all too easy to get the Mini ignition timing 180° off in the Mini. Thankfully, the Mini expert from Niederadenau that rebuild the Mini gearbox, pointed it out to me before I tried to fire it up. But even after correcting this – the engine wouldn’t start. So instead of being able to use the sunny Friday weather on the Morgan – I ended up taking the HIF44 out and apart again.

When inserting the float needle seat, I followed a recommendation to use Loctite 577 on the threads to seal it. This was a mistake – or I used too much. Either way, small yellow particles were clearly visible in the float chamber. And when doubling checking the float height I noticed a mistake I made. The SU manual says to measure the float height when the needle is in shut position. So, you need to carefully press it down and then check that the dot on the float is approx. 1mm (+/-0,5mm) below the straight edge on the chamber.

Cleaning and correcting this finally allowed me to fire up the Mini engine. All of this helped to get the Morgan back to a running condition. Today, I took of the Weber again (I stopped counting…. 6th/7th? time), cleaned the float chamber/needle and checked the height again (which was correct). I am confident that the carb is assembled correctly. A difference when setting the ignition timing between the Mini and the Morgan is the handling of the vacuum advance. On the Mini you just had to disconnect the hose – the Ford manual specifically say you need to plug the vacuum port. I didn’t do this before, and it made all the difference.

Having both engines in running order again is a big step forward. The Mini is almost complete, and I am looking forward to having it back as my daily driver. The Morgan project has a bit of a delay – but now I feel I am getting back on track.

All should work in theory…

Leave a comment