Oh well… the trusted Morgan expert of my choice is busy for the next couple of months. Good for him – a challenge for me. Theoretically I could just wait until he has time. There is no deadline, no external pressure to finish the car. But for whatever reason I have the desire to finish the project in the next couple weeks. After a few calls and some research I found two garages (Ford specialists) that I might contact for help. I might contact those. But during the call with André today, I developed enough motivation to continue to try solving the problems with the engine myself. Actually – I should say fuel/ignition systems. Well, maybe just fuel/carb system.

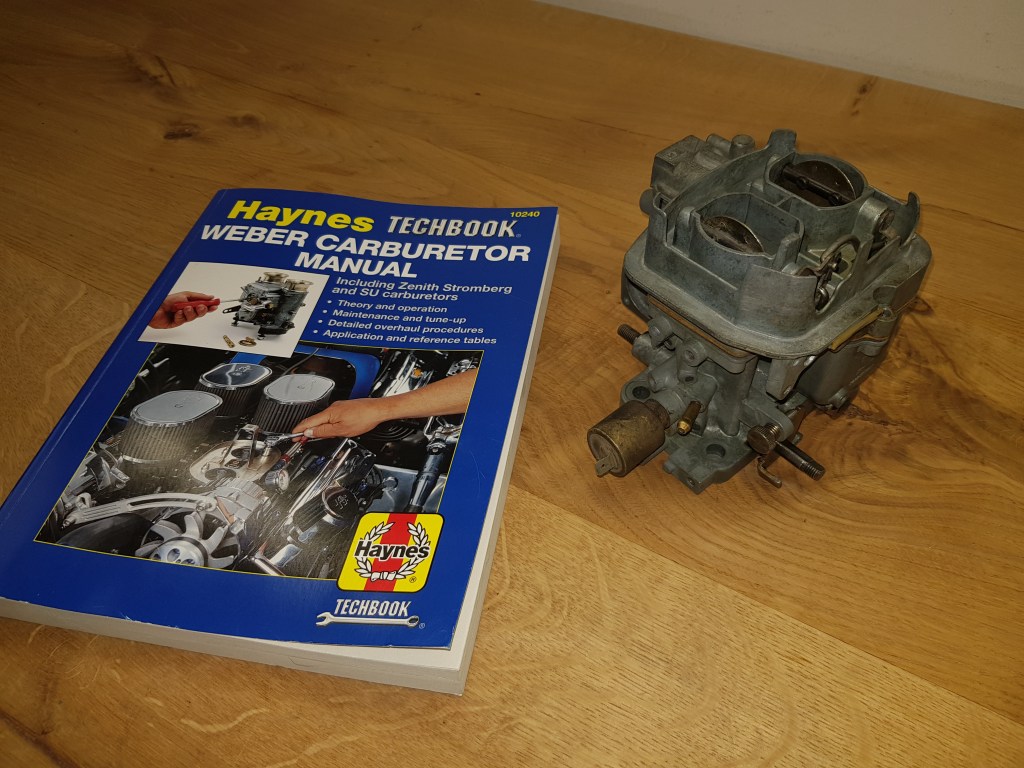

After the short test drive yesterday, the spark plugs clearly show that the car is running too rich. The air/fuel mixture screw is still on base adjustment (Haynes techbook says “turn the mixture screw in until it is in light contact – hen back it off 1 full turn”). André made the comment that it might get air via the secondary channel. I decided to take the spare Weber 32/34 DFT apart again (the one I took off a week ago) – check all 81 assembly steps from the techbook carefully again – and double check the adjustments again. Very beneficial: the left part of my desk in my home office is completely empty and disassembly can be done even via phone calls 😊

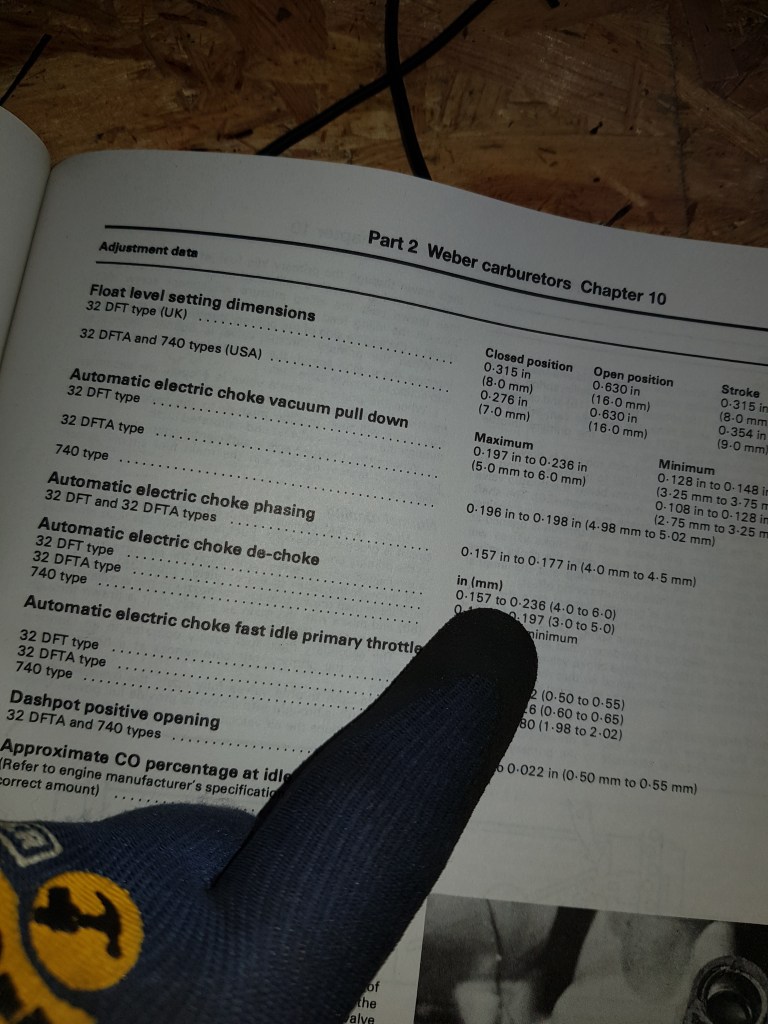

After work I then started following the assembly steps again. It is important to note that chapter 10 of the Haynes Techbook covers both the 32 DFTA and 32 DFT type carbs. There are two exploded view diagrams and the numbers of the parts are different. Both the disassembly and assembly instructions list the DFTA components. During the process it is therefore crucial to check that the part number listed for each step corresponds to the DFT type carb. And even though I had the Weber apart for the 6th or 7th time – there are always a few little things I find I could have done better.

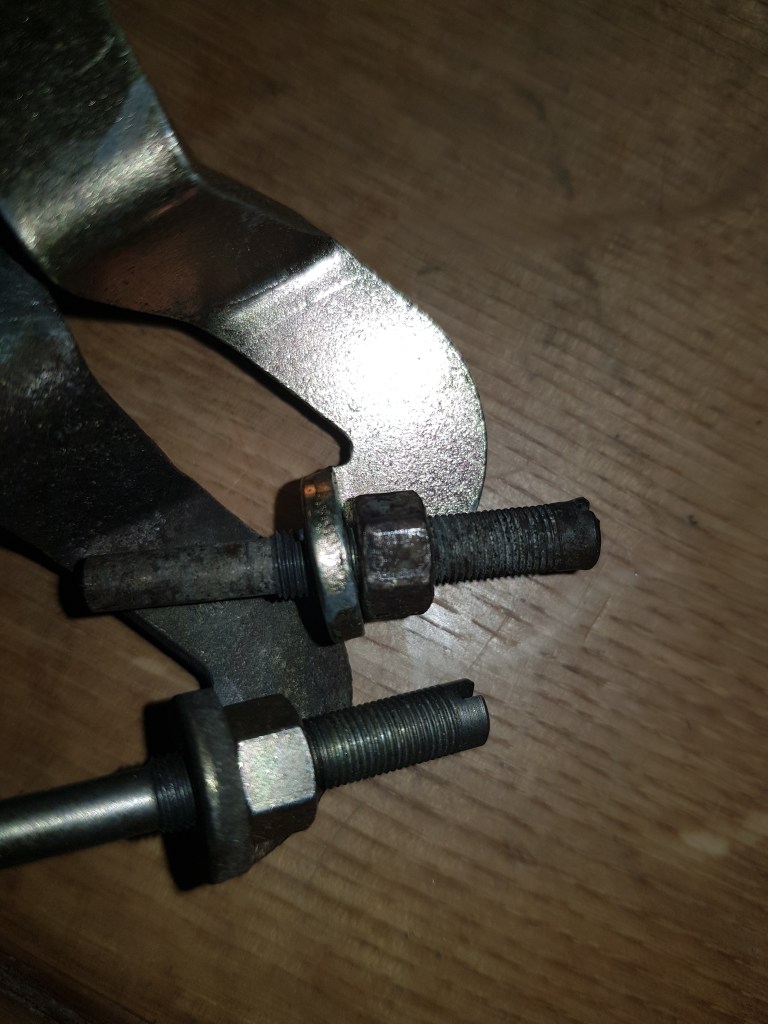

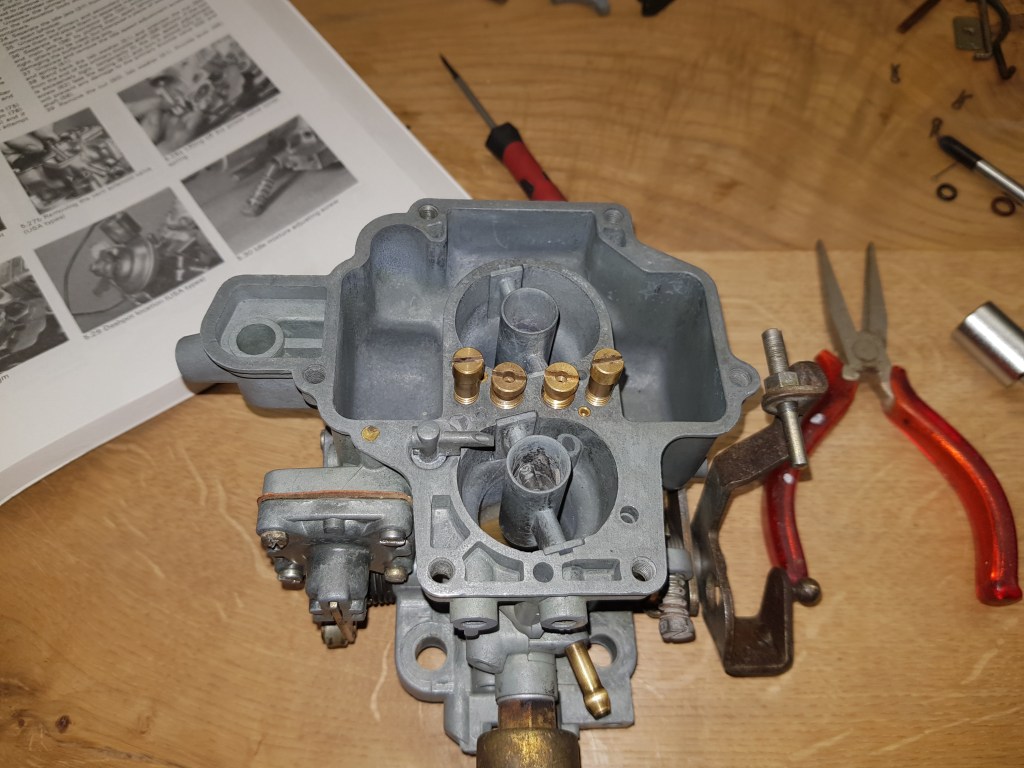

Luckily, I now have two complete 32/34 DFT 4B (Ford/Weber 81 SF AB) carbs, one 32DFT (Ford/Weber 78 1F AB) as well as some additional parts from a broken 32/34 DFT 6, service kits and spares from Webcon. I took my time during rebuilt the carb today. Whenever I had the choice between spare parts – I carefully checked which one is looking better and is correct for the DFT 4B. This time I followed the instructions completely step-by-step – including to fit the pump-cam and nut on the primary throttle shaft in a soft jaw vice – before inserting it into the carb. I think this helps to ensure that the throttle closes completely. I also found a better washer for the idle cut-off valve. The one I had was clearly leaking. With the experience from the HIF44 I paid special attention to the float level. And here I found my biggest mistake. Step 68 says: “Hold the carburettor cover VERTICALLY…” The float needs to hang down from the fulcrum pin with the float arm just in light contact with the needle ball. Previously I measured it while it is laying in the desk. This will press down the needle ball and the results in completely wrong float adjustment.

Also – during the process I managed to at least assemble one Autochoke unit from the 3 broken ones I had. They are all slightly different and the plastic parts insight not serviceable items. Getting a new AutoChoke unit is difficult and if you buy a used carb – chances are that this unit will be broken!

The biggest struggle I still have is with the instructions for the vacuum pull down adjustment. On none of the variants I have I can use a screwdriver to hold down the diaphragm spindle. The “adjustment screw” is sealed with a plug on the part that came from my Morgan – ergo: vacuum pull down cannot be adjusted properly. Choke-phasing and dechoke adjustment were fine. Fast idle adjustment might have been the main issue yesterday. I noticed that the thread on the throttle lever is damaged. The original Weber on my Morgan had a broken AutoChoke unit and now I understand that this was caused by the lever and angled fast idle screw. I suspect that somebody doing the setup on the car in the past must messed this up. With a working spare throttle lever I could adjust the fast idle setting – but I need a different feeler gauge with a pointy tip to exactly measure that the primary throttle valve has 0.5 to 0.55 mm distance to the outer barrel wall. This setting needs to be checked again.

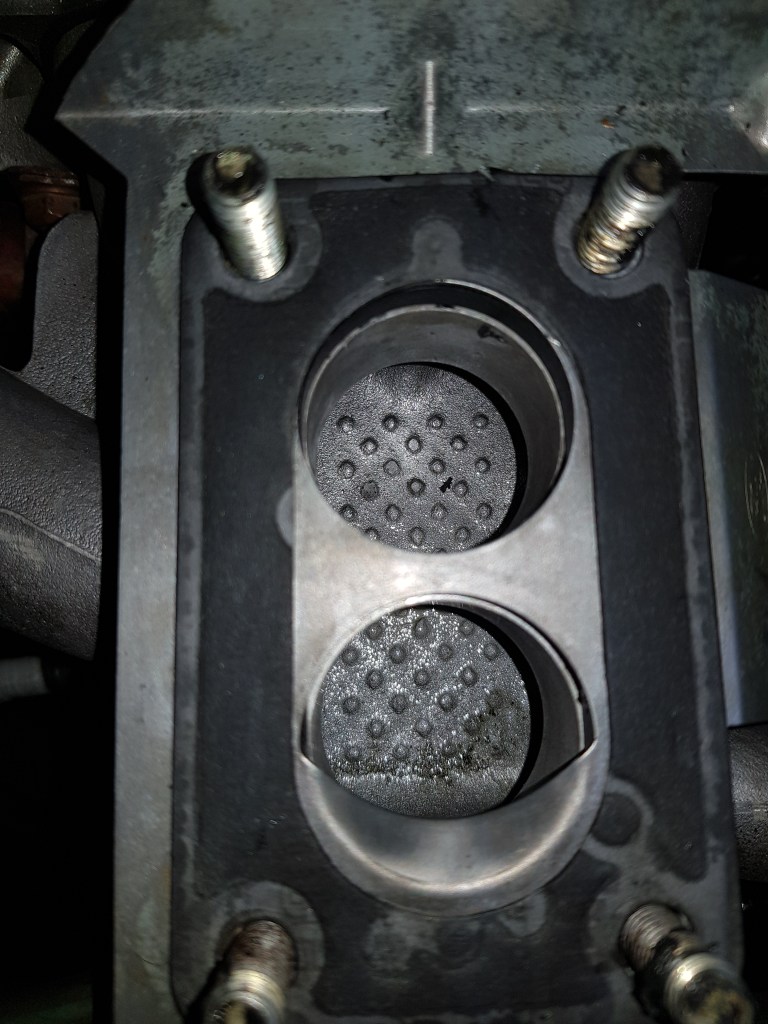

Swapping the Weber on the Morgan is an easy job. First – there is just so much more room in the engine bay compared to a Mini. Secondly, I now have sufficient practice. 30 minutes later I was able to try it out – the car started right away but the Choke/Fast idle is now too low. As it started to rain again, I decided to do a test drive tomorrow and correct the float level on the carb I took off. I could not find any other issue with this carburetor. As this Weber has a complete new AutoChoke assembly – I might swap it back. Fingers-crossed the work tonight will allow me to do more test drives and decide on what to do with the gearbox noise.

Starting over yet again

All spares sorted

the right accelerator pump diaphram assembly was new – but broke on this use…

selecting the pump cam lever (130 is not correct)

not sure why I did not see this before

double checking all jets

trying to get one working unit

some of the autochoke parts are pretty worn out

too much fuel – even visible in the mainfold

trying to figure out vacuum pull-down adjustment

Miffi (the Mini) will be moved out of the garage in a few days…

Leave a comment