F__k yes !! One problem solved. Finally. Engine is running. Now, I have more fun than the monkeys in the zoo (… the song Floating from Jape was playing on the radio while I was in the garage – look up his album title 🙂 )

It was a stupid mistake. Something I have checked a couple of times over the last couple days. But I now realized that I made a parallax error. But before I get into this – let me pick up where I left off yesterday. After checking the distributor for another time and testing both Weber carbs again – I noticed that there is too much fuel in the carb. I already linked to a video from on “D3Sshooter” before. (1) Carburettor Vapour Lock & Flooding symptoms , diagnosing ,causes and fixing. – YouTube Really worth watching if you have any engine with a carburetor.

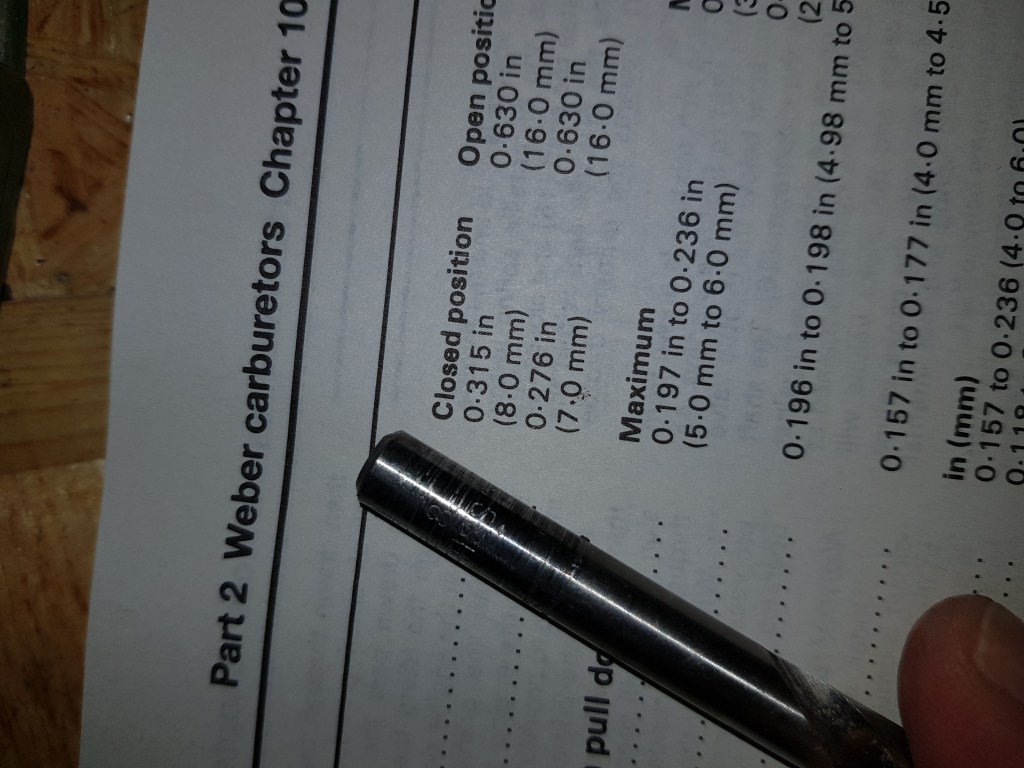

I watched it a couple of times and somehow had the feeling that is the root problem. As I replaced the needle seat and needle, cleaned the components a couple of times and made sure that the needle holds pressure (also explained very well in the video) – the only thing left was the float height. The Ford Escort Xr3 (due to the CVH engine the Morgan has) manual states “Float height – 34.5 to 35.5 mm”. And with the Video from D3Sshooter I checked this with the carburetor top part laying flat on my bench.

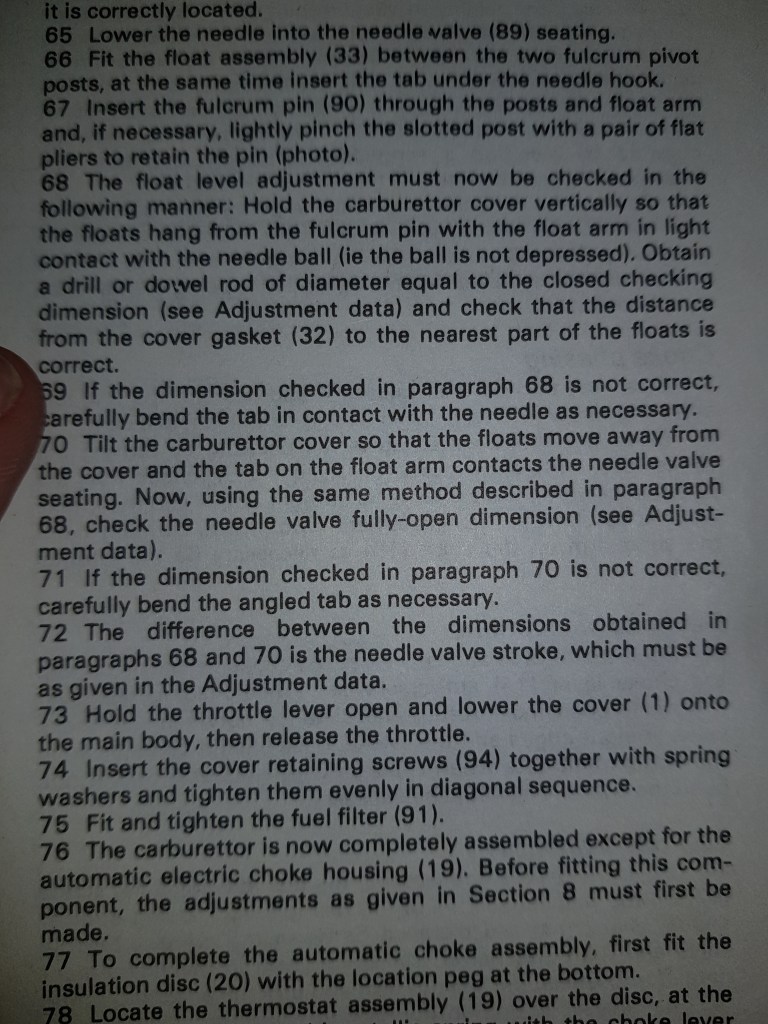

A couple days ago – equipped with the Haynes Techbook – I noticed that it stated for my carb, that the float level needs to be checked with the carb top being held vertically. As I did a check of my Weber rebuild while the carb was on my office desk this week – I check the height with a caliper. Today, I found another excellent channel on Weber carbs on Youtube. (1) Air Fuel Mixologist – YouTube Somebody that obviously has a lot of passion for carburetors and knows what he is doing. If you are into old cars – subscribe both channels.

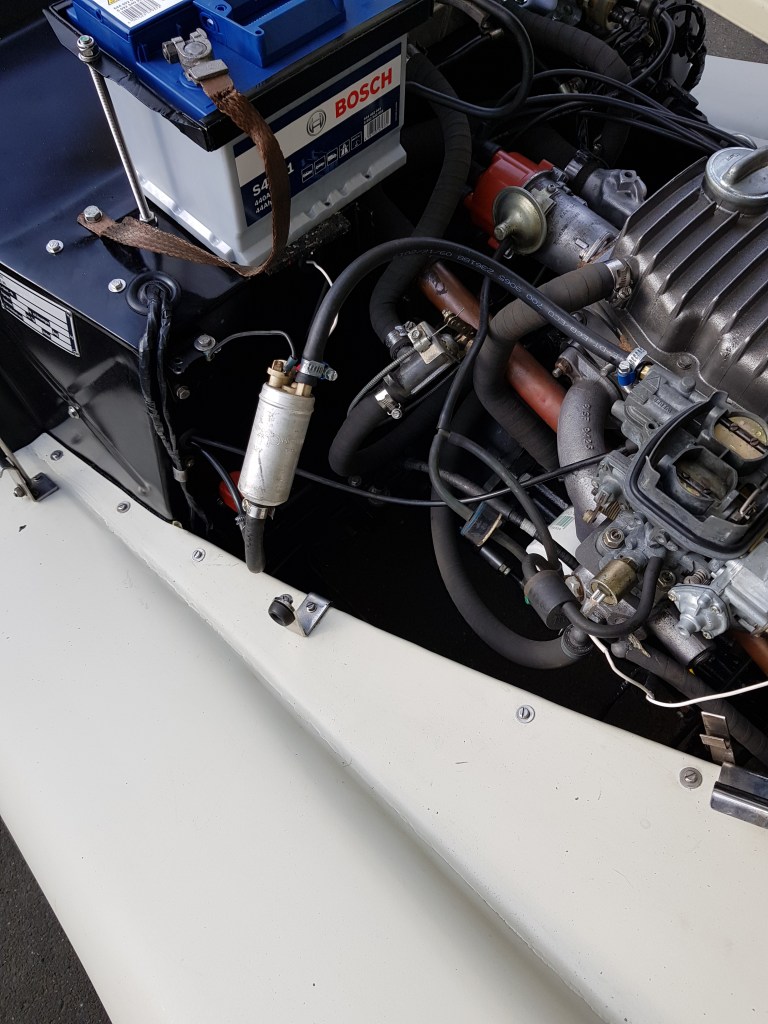

As I thought to have done the Weber setup correctly – I decided to remove the Facet fuel pump and pressure regulator I added during my restoration. The idea was to remove potential problems I added. The old pump was working before I started a year ago. Fortunately, changing the filter and pump was very easy. A good proof for the serviceability of my setup in case something breaks in the future. I checked that the pump delivers fuel – but the car still would not start.

Therefore, the only thing left was the Weber. The two Youtube channels above helped me a lot. And the only option I had left was to check it again. Using the Haynes Techbook I followed the instructions precisely another time – but this time I used a drill (just a they write) instead of a caliper to measure the float height. And for the close position the problem was clear right away – even though the caliper seemed to show 8mm – the drill bit would clearly not fit. This was the point that I noticed I ran into a stupid parallax error. I looked at the caliper from the wrong angle…

I carefully bend the float arm to get the correct distance. From my Vespa restoration I knew that giving full throttle can help to clear a flooding problem on startup – and this was exactly what helped here as well. I now have a relatively smooth idle. The engine ran for a few minutes without issues. Next I will swap the fuel pump again and check the ignition timing yet another time.

I was concerned that the new Facet pump is too strong and that my pressure gauge might not be working correctly.

So I took it out…

… and just used a wire to power the old pump which was installed in the front.

Massoli filter/regulator out and old pump in…

Checking the Haynes Techbook for float adjustment another time…..

They write to use a drill bit or dowel…. 8mm drill

The ball/needle just needs to be touched – the 8mm drill fits under the float

demostration on how easy it is to run into a parallax error

8mm – different angle….

the 16mm (open position is a bit less critical – also used two 8mm drill bits but could not make a picture (not enough hands…)

Crucial: no dirt, new needle and seat

funnily -after setting this I just checked it the way the Ford manul specifies it. I guess it would also work (34,5 to 35,5 mm is noted there)

I think the Haynes vertical check using a drill is better.

Leave a comment