What a beautiful Sunday. The weather was perfect and after an extensive walk with the dogs in the morning I got into the garage just after noon. After pushing the Morgan back into the garage last Tuesday, I concluded that my “Weber overhaul” must be the root cause for the issue. It was clear that I need to read the “Haynes Techbook for Weber carburetors” again.

As the engine starts OK on a “cold-start”, the explanation in the Haynes Techbook on how the 32 DFT works pointed to issues with the AutoChoke. And pretty much all of the essential adjustments that follow the 82 assembly steps in the book, are done on the AutoChoke unit. These are idle, vacuum-pull-down, choke phasing,dechoking and Fast-Idle. And when going through the chapter again, reading it line by line (sometimes multiple times) I slowly started to understand that I previously did not read carefully enough, misinterpreted a few instructions, and made mistakes.

I actually started with this on Saturday afternoon and focused on the choke phasing. At that point I had the Weber still on the car and just removed the top assembly. The short choke lever arm insight the Autochoke unit must be bend – and as I did not want to damage the lever weight in the unit – the only way is to take it out, adjust it and check again. In an email exchange with the “Air Fuel Mixologist” from Youtube – he asked if I changed the choke diaphragm. And at this stage – just from the email and just having read the chapter again – I finally understood how to check and set the maximum vacuum-pull down. As the adjustment screw in my carb had a plug – I did not check it correctly before – but the instructions specially says that the plug needs to be removed !!! This is best done with the Weber on the workbench – so on Sunday I took it out and did the job outside the garage enjoying the sun.

The instructions for the minimum vacuum-pull-down are still unclear to me. The “modulator spring” needs to fully compressed. I am not even sure which spring is meant. I assume it is the one on the end of the diaphragm spindle. But my Weber does not have a hole for screwdriver to do this. Using a caliper I tested how much travel the spring has. The 1.5,mm is less than the minimum pull-down mentioned in the book. So maybe I measureing the wrong setting? The Fast-idle adjustment also leaves some uncertainty. I was guessing about the “highest section of the fast-idle cam” is. The 0,5mm feeler gauge fitted at some point – but it was pure guess work.

Nevertheless, with those changes the engine starts well, regardless of if it is a cold or warm start. On a few short test-drives the accelerator responded well. When the engine is warm, I had two cases with the idle speed did not come down again when stopping at a traffic light. This needs to be looked into but tuning will be done at a garage that has a CO2 measuring possibility. I am also glad that I have sent my spare carburetor to for an even better overhaul to an expert. BTW: delivery times from and to the UK seem to get better. Spare parts from Melvyn Rutter arrived within a week with TNT and sending the carburetor to the UK only took 4 days with DPDHL. Quite an improvement after all the delays I had in the last couple month.

The main objective I wanted to clear in this restore phase has now been completed. Changing and tuning the Weber can be done even if the car is painted. Gearbox and clutch are working. A new distributor alone with a fitting original Ford connector cable ready. So – next up is the appointment with the paint-shop later this week.

new parts from Melvyn Rutter

The easiest adjustment – idle screw

choke phasing should be 4mm from the straight edge for the choke valve to the intake side wall. Checking is done with a 4mm drill

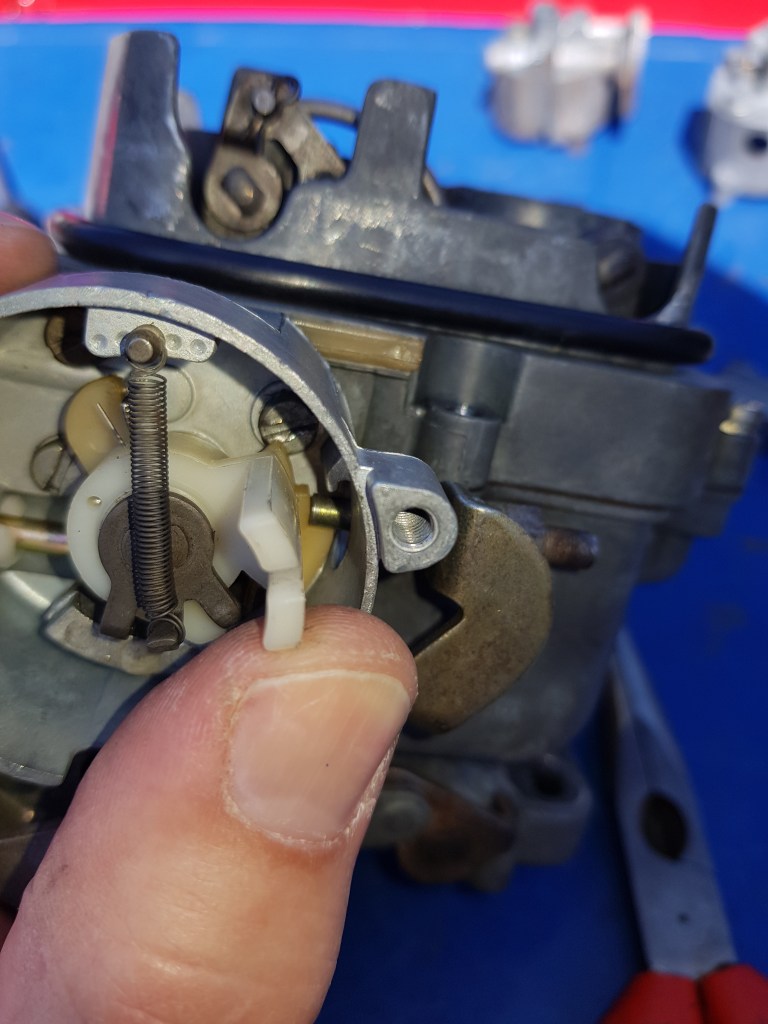

These lever arms have to be adjusted. The short arm is important for choke phasing.

here marked. It is all to easy to damage the weight when trying to do this without taking it apart. I did not want to take my chances…

NOS (New originial stock) Ford distributor replacement cable…

cannot hurt to check the cables

Mototronics distributor replacement 89SF12100 BA

maximum vacuum pull down should be between 5 and 6mm. carefully push the diaphragm spindle to that it pushed again the adjustment screw

There are a seal on this before – the screw had to be turned in quite a bit

guessing that this is the modulator spring

it can be pressed to ~1.5mm. the longer choke lever arm with be pushed by the plastic part

Choke phasing is measured when the throttle is on the middle position on the choke lever

dechoking is done by holding the throttle open and pushing the choke lever anti clockwise. The distance of the choke valve is again measured with a drill and should be 4 to 6mm

Fast-idle should be 0.5mm

What a relief – tuning can certainly be better – but at least the engine is working and the next phase can start

Preparing the garage. For paining I need to partly take the car apart again.

Leave a comment