It has been a while since my last post. A draft announcement for the completion was already ready. But the truth is – a major “f&$k up” occurred and it is my own fault. The already happened last month – it just took me a while to digest it all and make it “public” here.

While I completely underestimated the time required to get the finishing touches done – a lot of progress was made during my vacation back in July. Battling with the dashboard and Lucas indicator stalks, crafting covers for the Rutherford rear suspension, cleaning wire wheels – I crossed off one unpleasant task after the other from my ToDo list.

My goal was to take part in a regional Morgan Club Deutschland meeting in Oberpleis – 35km away from home on the last day of July. Before going there, the new Lucas indicator stalk caused me a bit of headache and a couple short circuits. I decided to go back to the old indicators stalk – which is in a pity state, but at least it works. Another item on my task list were the new covers I need for the Rutherford rear suspension. After bleeding the brakes another time, fixing the passenger door alignment, installing durable dots for the weather equipment, fiddling around with the Weber to reduced the idle revs – I was finally ready to go – 30 minutes before the meeting started.

And the engine sounded great. The first few kilometer driving through city traffic went flawless. To cross the river Rhine – I had to take the Autobahn A565. There was quite a bit of traffic and I drove carefully because I wanted everything to set it properly.

Just after crossing the North bridge – a loud, unexpected bang and blocking rear wheels led to an abrupt, unpleasant full stop on the middle of the Autobahn without a service lane. In hindsight, I was so lucky that nobody crashed into me. At first I could not get neutral engaged- so moving the car was impossible. It felt like an eternity until the police and the ADAC showed up.

The police blocked the traffic from behind- I was able to get the car into neutral and we pushed it to an emergency lane pieced a new hundred meters down the road. About an hour later the ADAC dropped me and the Morgan back at my garage. Initially I had the feeling that the gearbox caused the issue. But, the root caused was easily identified on the next day. And while it is embarrassing, stupid and painful – it is my fault that I did never investigated properly where the oil drops on my garage floor came from over the last couple month.

To my defense: The rented 25 square meter garage always had a pretty dirty floor with lots of oil stains on it. And over the last 8 month since I dropped the rear axle onto the chassis – the car moved around on the dolly to various spots – just as I needed the space. Looking back – I even remember to have cleaned up oil from the floor after moving the chassis for the first time – but I thought that I just spilled it while filling up the axle. After I drove the Morgan to the paint-shop they complained about oil under the car – but at that time I thought that this was engine oil due to the missing oil pressure gauge. My assumption is that on the first couple drives – the gearbox oil drain screw started leaking. It is entirely my carelessness that I never double checked it after getting it back from the UK.

Well – it doesn’t help. The loud noise was caused by the rear axle locking up. And this in turn was caused by loosing most of the gearbox oil through the lower drain plug over the last couple month which I did not double check. As mentioned: it is painful and embarrassing but I need to be true to myself – it is my own fault that I a) never thought of the rear axle oil and b) never checked the drain plug again after installing the axle on the chassis.

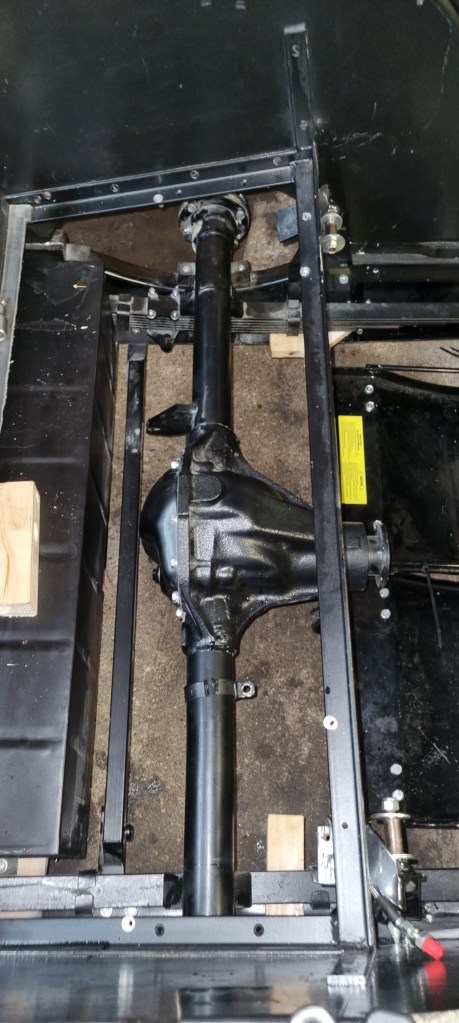

So – after my vacation I ended up doing the task I wanted to avoid: Removing the rear axle from the Morgan with the body on the chassis. Not that this task is impossible. As a matter of fact – it turned to be easier than I expected and only took me 6 hours in total. Nevertheless – it is something you clearly don’t want to do. The visual inspections after I go the axle on my bench is not as bad as I feared. Maybe I just killed the inner and outer pinion bearings. Well, I will drop of the Salisbury 7HA next month at JB Engineering and hopefully Billy can fix it.

The orgininal steering column has a little indend for the correct position of the indicator stalk

The EZ powersteering does not have this and I am hesitating to take of the Dremel or drilll. to add it

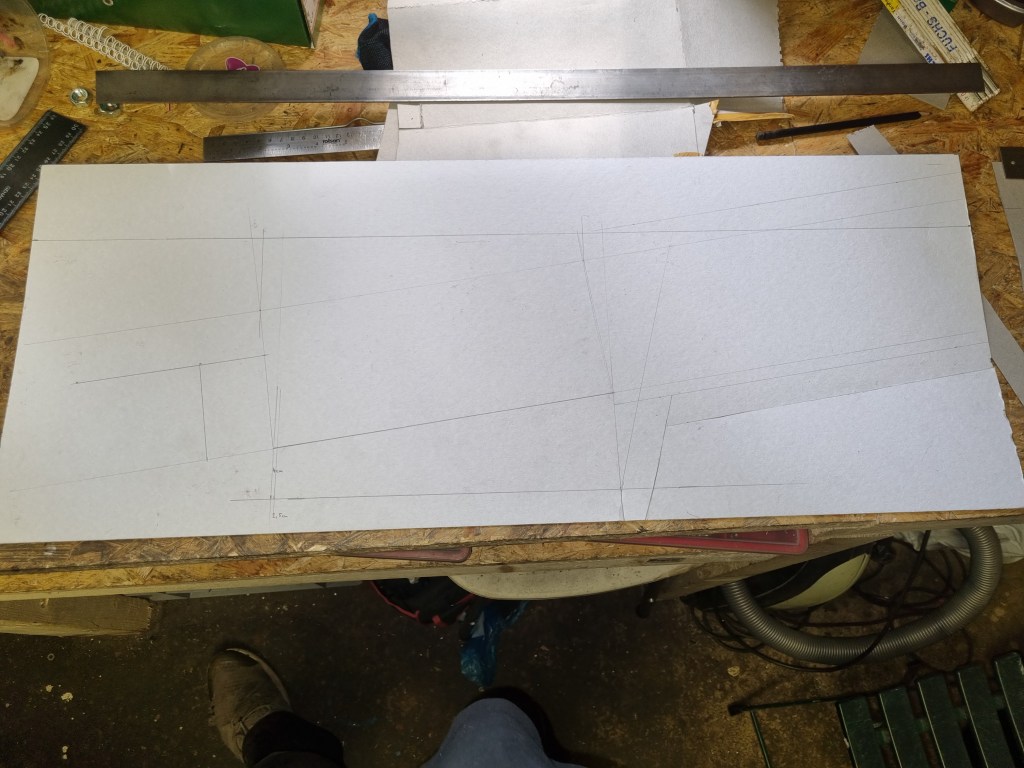

CAD – cardboard aided design

first test

The seat can slide over the cover easily

first attempt

I was allowed to use the tools in the body shop which made creating the covers easier

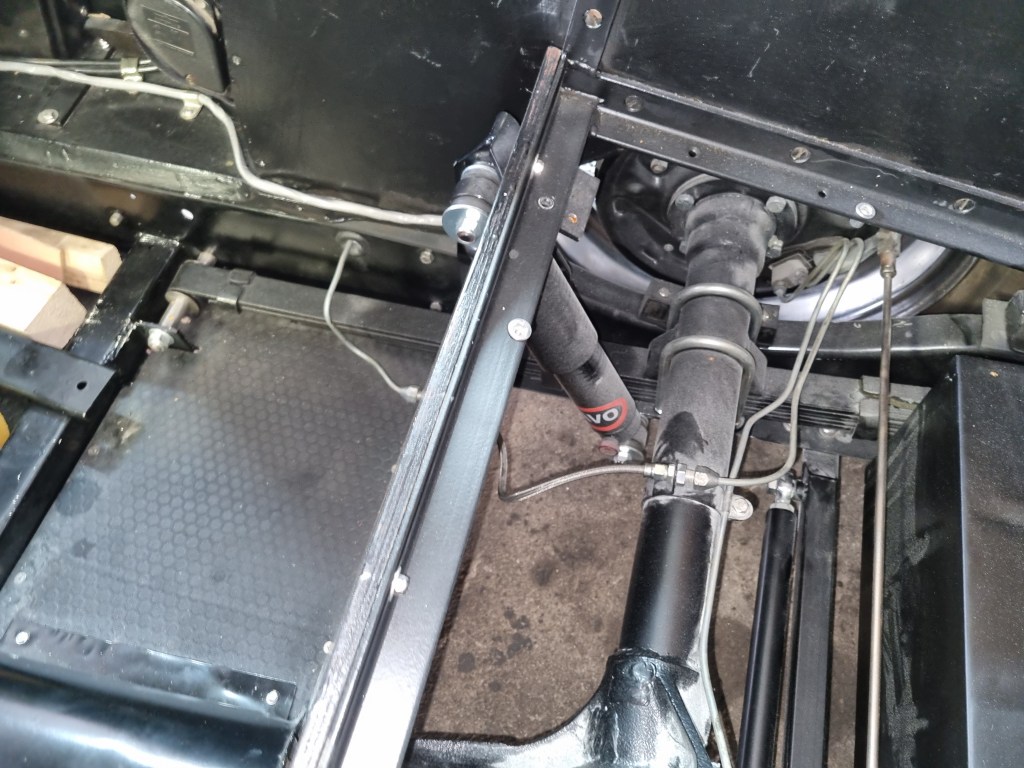

The brake line on the right side of the car is a challenge

unconventional and maybe a bit crazy… I moved the location to the Rutherford bracket for the rear brake line

Yes – it is just 2cm away from the rear wheel… not perfect and subject to change

The new covers in place. Not sure if I will cover them with leather or carpet

Ready to go – about 45minutes later I killed the rear axle

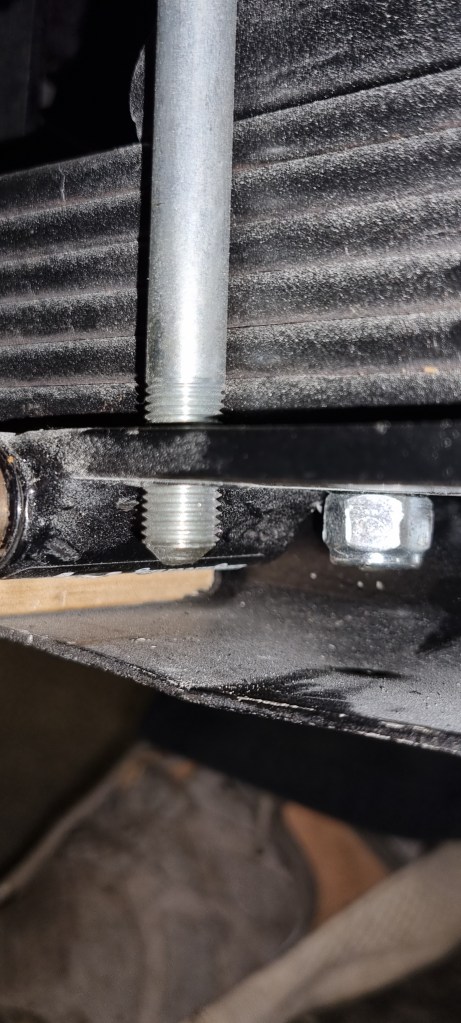

The stupid split pin on the right side turned out to be the single longest task. 30min fight until it went out… compared to 3min on the left

This tool is required to pull the wire wheel hub… Thanks to André for letting me use it during his vacation

Remove the castle nut and put it back on with the flat side facing up and flush with the axle shaft. You want to avoid flying wire wheel hubs…

With the hub out of the way the brake anker plate can be removed.

These sit ontop of the anker plate

I bolted them back on to avoid dirt getting into the bearing

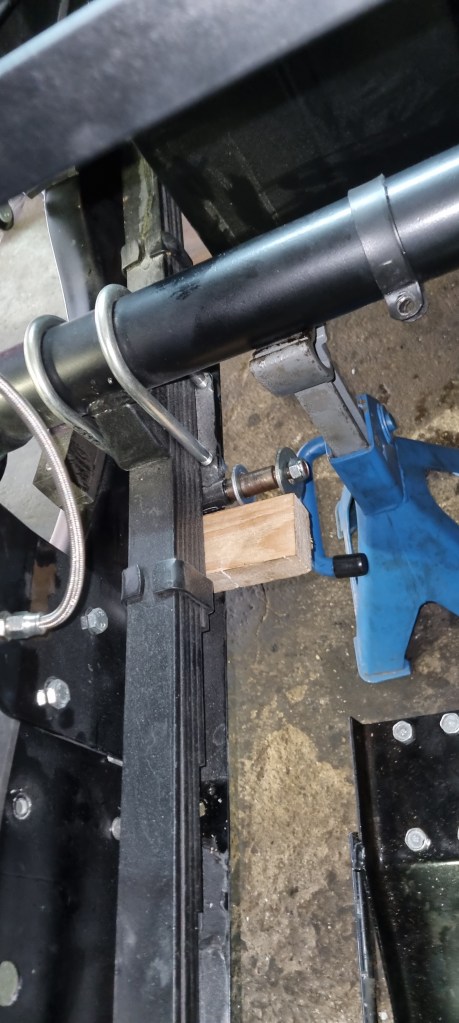

I repositioned the axle stands – away from the chassis under the rear axle. my weight in the chassis was enough to get a piece of wood under the leaf spring…. yes I need to go on a diet…

you need the wood under the leaf spring to remove the nuts. Make sure to have another pair of axle stands or a jack under the chassis

once the U-Bolts were removed I repositioned the axle stands unter the chassis again

The Salisbury 7HA is heavy – but I was able to lift it and remove it from the car on my own.

Make sure to prepare axle stands somewhere to drop the axle onto..

Two axles on the workbench. To the left: Salisbury 7HA for the Morgan 4/4. To the right. Salisbury tube style axle from an MGB

nothing seems to be broken… hopefully the pinion is OK

Leave a comment