While the entire family was able to end our Corona quarantine earlier this week – I didn’t really have much time and motivation to work on the Mini and MGB recently. Maybe the only Covid19 symptoms I had were a lack of any motivation and desire to sleep a lot. But as I will change jobs in April, I have a bit of spare time now. This step wasn’t planned or clear 6 six weeks ago but sometimes change comes faster than you think.

The Mini40 front suspension parts came back from coating weeks ago and I already completed the top arms last year. Now it was time to finally reassemble the front subframe. The only parts that weren’t ready were the swivel hubs. The shipment from Mini Sport is still being held by UPS. It is in customs/in warehouse for 6 weeks now. The tracking shows the import customs has been clear twice and I called them dozens of times. UPS is a nightmare in terms of customer service. Even if you get someone on the phone – most of the time they do not help you at all. If I would get 5€ for every time they told me: “we call you back” – 20% of the 600€ shipment would already be paid.

Therefore, I quickly got some parts for Kischka in cologne this week. After a night in the freezer the new races for the wheel-bearings went in easily. As the hubs were blasted and powder coated – I had to thoroughly clean the grease lines. Before installing the new ball joints, I squeezed a load of grease through the lines which still included a lot of particles. Having rebuild a few subframes now – I forgot taking pictures – in the end it is really straight forward once you have all parts sorted. And yes – I did knock over the locking ring on the ball-joint after I took the picture below of all parts 🙂

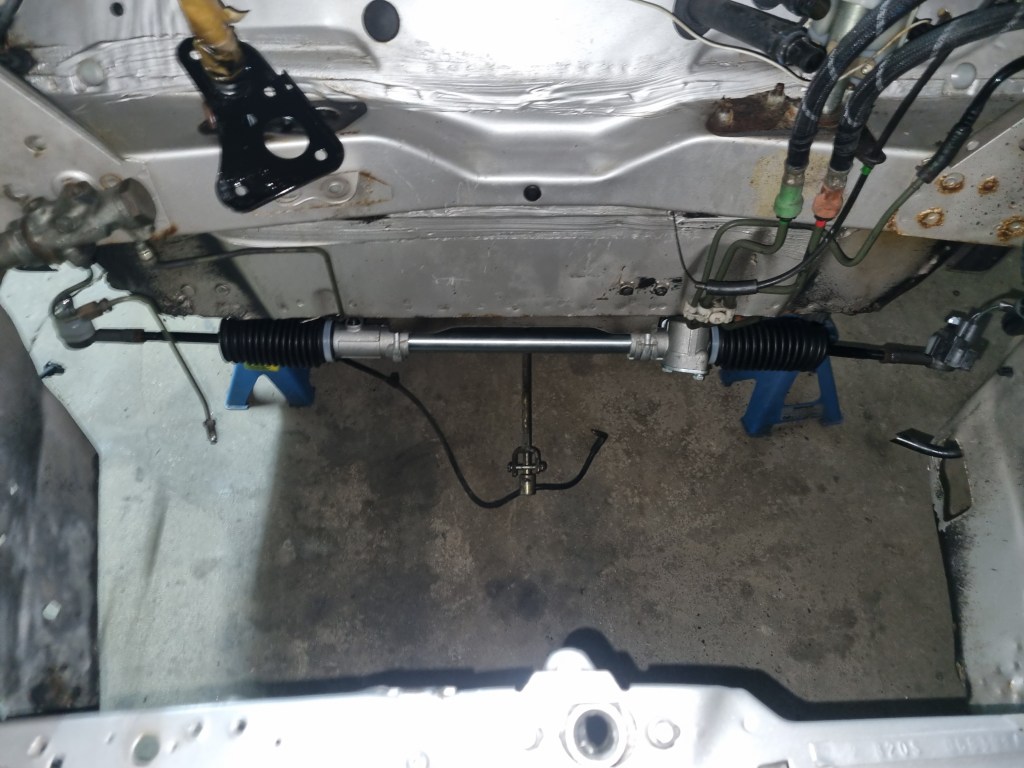

One thing that took more time is one of the new rubber cones. The metric compressor needs to be screwed into the cone from the top – but on one of the cones the necessary hole in the rubber was missing. Getting this cut turned out to be an unexpected 45min job – what a nightmare. But once this was done – I could move on to new steering rack. The old one has play and both inner tie rods are loose.

For the Mini I opted for a new rack. This costs 80GBP for an MPI Mini and was the suggested better way. As servicing and rebuilding the MGB steering racks (two LHD and one RHD rack) is on my task list – I might try my luck on the now obsolete Mini MPI rack as well. After installing the new rack, I put the subframe in – but then remembered that the Mini Sport delivery also contains new poly washers and bushes for the subframe.

The rest of the day went into cleaning the garage and workbench. A little interested helper (who lives close to the garage yard) stopped by for a cup of tea. He pointed to a box with parts I got with the new bodyshell for Mildred. In it I found the old commission and chassis tags. GHD5-199276 indicates that the car/replacement shell was most likely built in Jan/Feb 1970. Production in 1970 started with the number 195915 for the GT – so this shell was the 361th MGB GT in 1970.

And these tags brought back a crazy idea…. Mildred might face an identity crisis soon…. stay tuned for what I mean…

– it would contain new

Leave a comment