Finally, the Morgan is on the road again. After the catastrophic rear axle failure on July 31st, 2021 – I was able to do a first test drive with the repaired rear axle yesterday. But there still is enough work to be done. The new brake line went in easily. For my first attempt crafting new brake lines I am very satisfied with the result. As a before-after comparison I will add a picture from the disassembly phase in May 2020. One step forward.

The task I hate most is bleeding the brakes. Even though I carefully have gone through the steps like usual, the frickin’ Gunson One-Man-Bleeding system caused problems again. Like always I did a pressure test with the empty bottle, and this worked fine. My battery powered mobile compressor has a 16psi mode and I use this to fill a spare Mini tire. This is what provides the pressure for the Gunson – which in turn is made for up to 20psi – so everything should be fine here. The Morgan has the -in my opinion- somewhat unusual setup that there is only one bleeding screw on the left side. After pressing down the brake pedal a few times I could see fluid and a lot of air coming out. But what I did not noticed is that the screw to stop the pressure on the Gunson isn’t working properly. So, when I closed the bleeding screw – there was still more pressure coming from the Gunson and the cap on the master brake cylinder popped off (it did hold fine on the initial pressure test). A huge amount of DOT4 fluid got spilled everywhere – certainly, something you don’t want on a freshly restored car.

I ended up asking my wife to help me and bleed the brakes the classic two-person way and that worked out fine. As the Morgan is still lacking its interior, I also went ahead and removed the frame for the hood as it was rattling too much. I wanted to be able to hear if there are any unusual noises and sounds. With enough there is almost no noticeable sound coming from the rear axle. With the 3.3 ratio I immediately had the feeling that I need more revs before shifting – especially on inclines – but other than that I believe all is fine now. The brakes work much better than ever before – even without a servo. I am glad I upgraded to the HiSpec 4pot calipers in the front.

The short test drive however ended however much quicker than I hoped. First thing I noticed is that the steering and wheel alignment must be checked. Nothing too serious but still needs to be corrected. And as we had a sweltering day (~30° degrees Celsius) I got overly concerned about the engine temperature. The Smith gauge showed over 100°C and I could not tell if this is correct. I remember that my father often had problems with heat on warm summer days – especially in city traffic. For this reason, I decided for larger alloy radiator and added a Revotec fan. But the fan did not start. The fan is connected to the water temperature switch on the back of the CVH engine. It could be a cabling or sensor problem here – or the Smith gauge is incorrect.

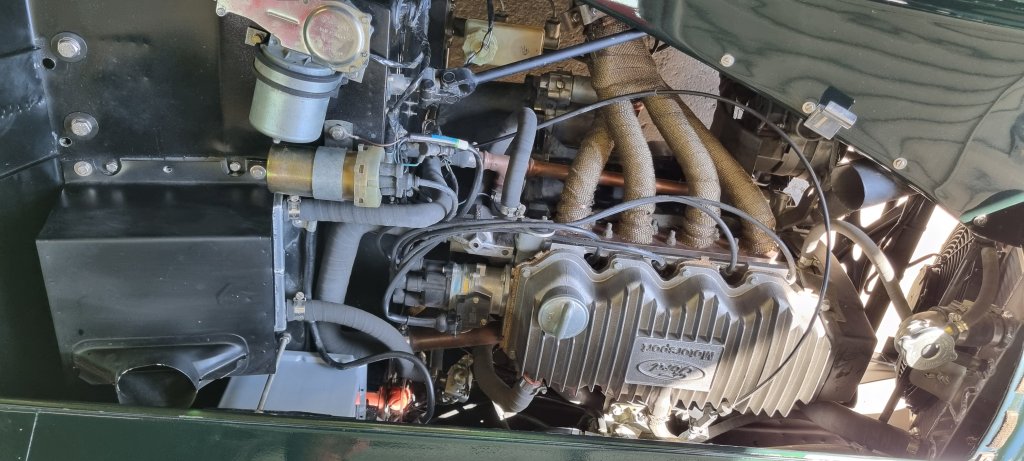

If the engine is running hot, I believe the most logical reason could be incorrect ignition timing or carburetor setup. I really tried my best with the Weber 32/34DFT overhaul and tuning – but after the excellent experience with Viktor Günther Motorsport I had with the Weber45DCOE on Maggie (MGB GT), I decided to reach out to them and ask for an appointment. In the meantime, I will check the fan cabling again.

Leave a comment