I spent the last week in the US and got the advice to buy ARP bolts and a Fidanza flywheel over there from AcmeSpeedShop. The timing for the request was on too short notice I guess – in the end this did not work out. After a bit of searching this might be a good thing – the ARP bolts are even cheaper over here in France and the delivery is free. The Fidanza flywheel is something I might bring with me on my next trip to the US.

What I did find on Ebay however is an Enco 3/8 chucking reamer. This is the poor man’s alternative to the tool that Joe Curto was selling via MossMotors. The MGA guru has an update from 2011 that shows a reamer that does not have a fully machined chucking shank. The 331-1124 Enco reamer I got sent to my hotel looks like the one on the top of the article though.

As I have recently started the overhaul of three pairs of HIF4, three pairs of HS4 carburettors – this was the one tool to completely do all steps myself. When I helped to rebuild a set of HS4 carbs last year – we sent the bodies to an expert for rebushing. This was a) quite expensive (150€ plus delivery) and b) took three weeks. Two of the HIF4 pairs work fine with a new spindle. One pair has parts mismatch anyway – so I am not going to touch this. The HS4 from Mildred (the 73 MGB GT) also is fine with a new spindle. The AUD135 pair from Maggie as well as a friends AUD278 HS4 carbs (from a late 1968 MGB tourer) both need new bushes. I will test the process on my carbs first – but not anytime soon.

A weekend between two full weeks of business trips feels too short. Saturday started with picking up a few parts I had sand blasted as well as a few spare parts from Kischka in Cologne. I was concerned that the hinges might not work afterwards – but the media selected has a bit bigger and was easy to clean off. I coated everything with a thin coat of epoxy primer to protected them for now – they will be painted with the rest of the car when the day comes.

The rear Armstrong shock absorbers looked horrible before. I know that the right thing to do is to just get overhauled units and use mine as exchange units. However, I am eager to rebuild them myself. One unit has a leaking seal on the arm – this is going to be the difficult part to find. The rusty old manifold also turned out quite nice. Ceramic coating was on option I considered shortly – but for budget and timing reasons I decided to go with 850°C heat-resistant paint.

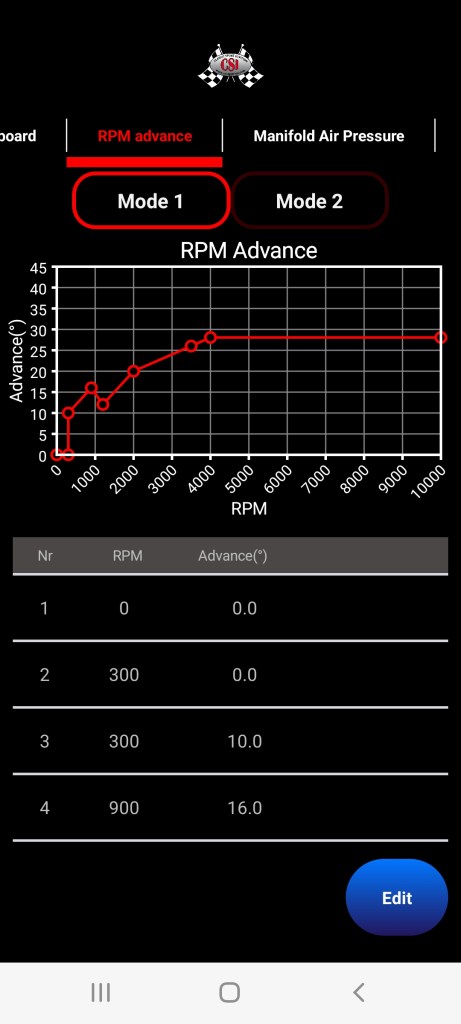

Then I had to rush to pick up a trailer and get Maggie to Cologne to GB Classic. While I can take stuff apart (and most of the time assembly it back together) – my fault diagnostic skills are basic due to a lack of experience in this field. I checked and correct valve clearance, cleaned the fuel filter and Weber, did a compression test that showed no issues, checked the timing of the CSI pro (in the app and a timing gun), spark plugs are new and looked good – still Maggie does not run as smooth as she did during the entire trip through the UK. The engine noise is hard to describe – unhealthy is what I would call it.

They have enough work over there – so it will take a while I guess until I hear from them.

Today I did some small jobs done. I prepared another prop-shaft for painting and new joints, installed the new oil seal in the Mildred’s 18V engine backplate but could not install it because my tube of Dirko HT red gasket sealant was nowhere to be found. Some people say that you can install the gaskets without any additional sealant – I don’t want to take my chance and will continue when I get back next week.

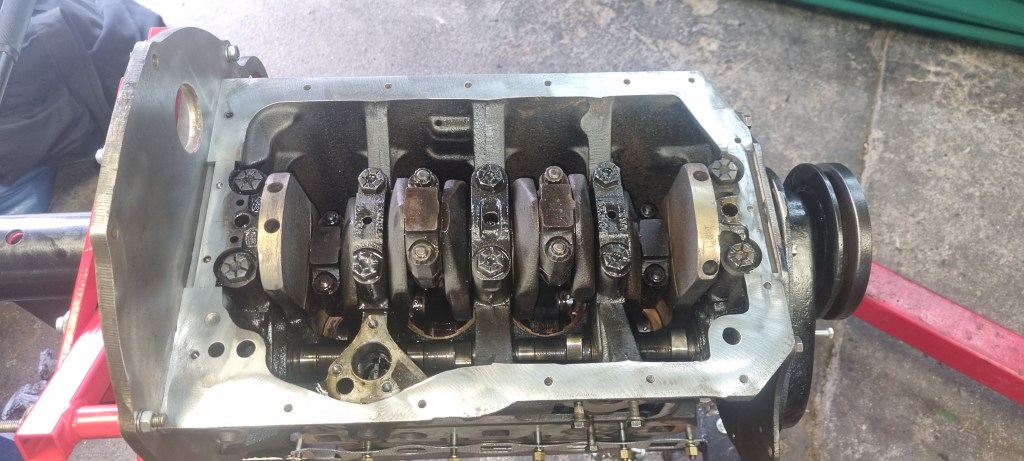

Last thing I did today was to clean up the engine surface for the oil pan and used an endoscope camera to check the cylinder walls – all four looked quite good as far as I can tell. Pictures didn’t work out unfortunately. The cam shaft has very light marks of wear – For now I will stick to the plan and get it running like it is.

Leave a comment