It was quite a bit of luck that the new Vredestein Classic Sprint tires from Autodoc arrived just in time on Friday. They are DOT23 – so from this year. Along with them new Michelin tubes at the Radspannerei in Fachbach. A big shout out to Stephan Oster – the owner and wire wheel wizard. I hope my (daily?! ) calls and stress I caused to finish C6622 for the BVAC2023 trip next week were not too bad for him.

When cleaning the wheels earlier this year I checked all spokes but did not notice broken ones. Stephan found and replaced a bunch on them. Turns out two wheels are newer stainless steel variants of the MWS YX459. As these are the straightest he marked them to be used in the front. Two older ones could also be centered well – these are for the rear. The worst one was previously mounted front left and most likely the root cause for the shaky test ride. It is still OK to be used as reserve.

A traffic jam on the way back made it almost two hour journey back. As there is no chance to get anything done the in the garage due to family obligations – the time pressure to get everything finished is starting to stress me out. I decided to apply fresh grease the front suspension. The car only ran 250km so far but checking my service notes that last time was almost a year ago. At least back to a rolling condition now.

Refitting the tunnel, interior parts and driverseat was also quick and easy. At 9:30pm I had the dashboard in, everything connected and started testing and thought that the stress is gone – but I was wrong. The dip beam still didn’t work. On Thursday I had double checked all switches, wires and fixed one of the Lucas flip switches – which gave me the confirmation that this is OK.

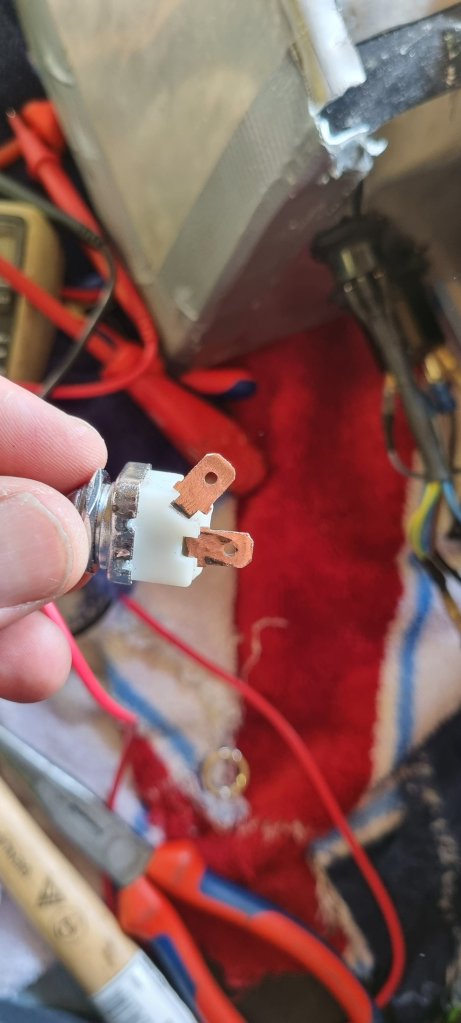

As the indicator stalk is still out – it was also easy to check the fuse box and relay wiring. No faults. This leaves the blue cable from the light switch is wired to the indicator stalk. The stalk was still on my workbench and easy to test. In normal position this is were either the blue-red cable for the dip beam or blue-white for the main beam get power from the blue cable. One the bench – this worked fine.

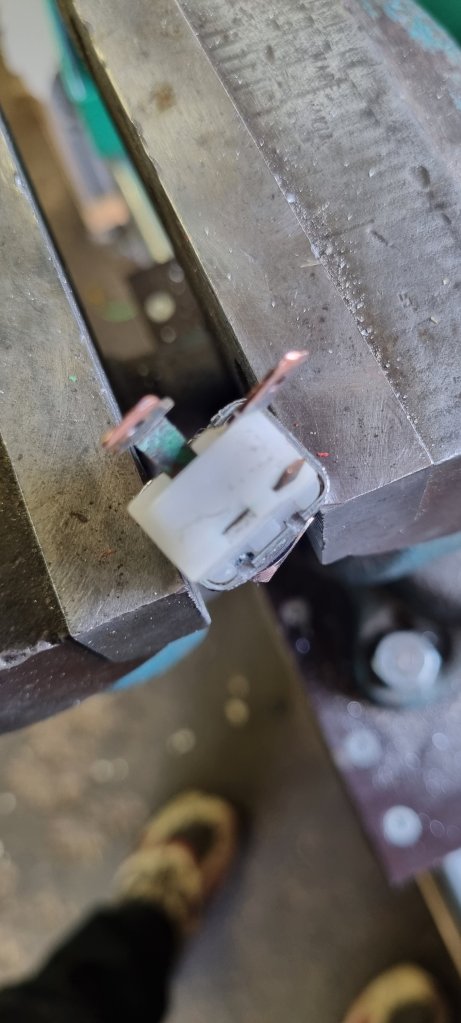

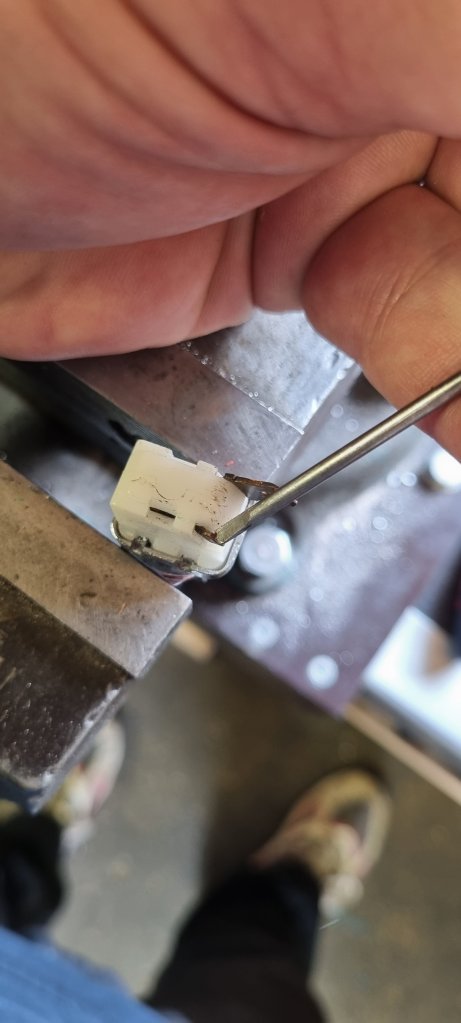

It took me a while to figure out that when I attach it to the steering column – it doesn’t work. As I wrote last time I intended to continue to use the old indicator stalk because it is bend in a way that it fit well with the dashboard. But on closer I inspection I realised that the plastic is broken. When fixed to the column all the contacts do not line up – causing the problem.

Bending the little metal tube of the Lucas SQB119 was something I was not looking forward to do. I already destroyed a new stalk on my first attempt. But this time I did not have an option and after some careful testing I found two pliers and a method to bend it.

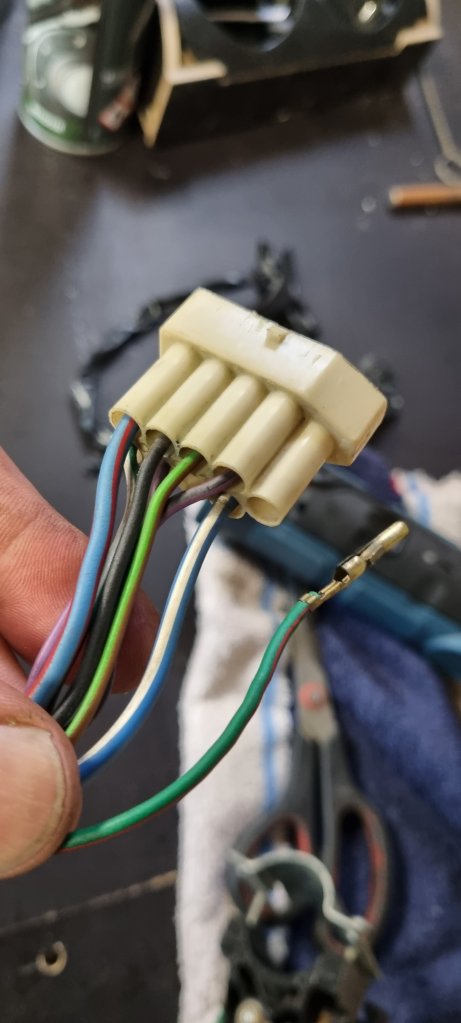

Back to the car: stalk and dashboard back in for the fifth time this evening. But still not finished as the next problem surfaced: the Lucas 9way rist connector of the new stalk does not fit the connector of the loom right away. It was already past midnight and a trip to Northern Germany just 6 hours ahead. Getting everything sorted for departure on Thursday will be quite stressful…

Leave a comment