Last weekend I worked hard to finish off the Morgan wiring. A closed-end battery cable connector had to be cramped onto the new brown cables from the fuse box. As I don’t have the right tool for this I drove over to Stephan’s workshop and borrowed the large hydraulic cramping tools from him. Next, I focussed on the dashboard cabling. As I removed all unprotected white cables (meaning ignition circuits without fuse) changes to the Voltmeter and the tachometer were necessary. The footwell LED lighting, Bluetooth receiver, Brantz tripmeter plug, and USB port were divided into two circuits on separate fuses, which resulted in a few changes on the connector plugs.

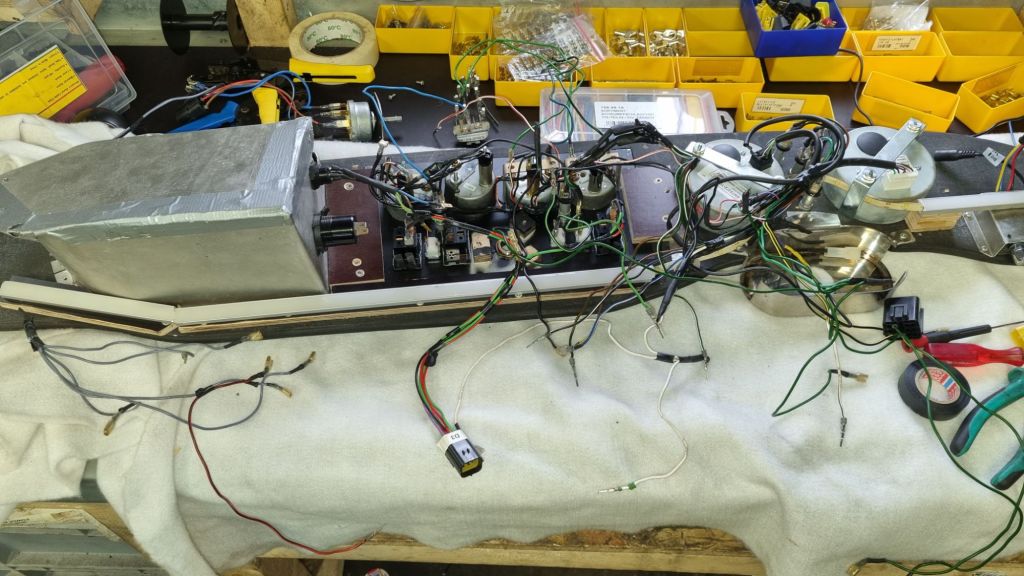

For the second time the new loom came back into the Morgan – still without the PVC wrap to test all circuits. On the bench I tested the connectivity of all cables and found now issues. If something isn’t working – the roots cause is with the dashboard wiring. Today I was able to complete the remaining tasks. New bullet connectors had to be crimped onto several replaced cables. I also did an oil change, renewed the coolant, greased the front axle, and checked the brake fluid with a tester. For all circuits I calculated the require Amps and fuse sizes. And to be honest – I was super nervous when connecting the battery for the first time in five months. I wanted to make sure that the oil pressure will be fine – so I left the ignition coil disconnected and cranked the engine over with the starter motor a few times until I could see movement on the oil pressure gauge.

Then I realized that I don’t hear a sound from the Facet fuel pump in the rear. The new green cable to the Inertia switch had 12V. This is a modification I made – in 1984 the Morgan did not come with such a sophisticated safety device 😉 But the fuel pump did not get power. It took a while before I remembered that I also have the SinoTrack GPS hidden in the loom somewhere. Although I cannot recall that I switched off the fuel pump remotely, I send the activation command to the device and the fuel pump immediately started working again.

After two short start attempts the engine was alive again. A minor oil leak at the connector from the pipe that runs to the oil pressure gauge was new – but other than this the engine runs fine. Most circuits worked out fine right away. The Revotec fan requires a 20Amp fuse – the 15amp one blew on first start. Lights and Indicators do not function properly – but I immediately remembered what I forgot and how to fix it. But there is still a major topic that bothers me: the clutch. For to me more precise – the cable and lack of free-play of the release bearing.

After working on the Morgan for a few hours, I shifted my attention to the MGB topics at hand. First of was the preparation of a MGB tailgate that will get chemically paint stripped, de-rusted and received cataphoretic painting. For this I need to drive to Bönen to drop of Mildred’s doors, tailgate, and the hood at Entlackerhelden.de. Last but not least I put on the overhauled Lockheed brake calipers on Maggie again. After driving 250km the brake squeal was back – but just on the right caliper. As I wrote before I suspected that the aftermarket calipers might be the cause. Overall, a straightforward task that still took more than an hour including bleeding the brakes. To my surprise there is hardly any difference noticeable on the calipers. The only thing I found is that the C-section of the brake piston were pointing incorrectly on the right.

The Mintex M1144 brake pads got a bit more cooper ease on the back and the sides of the metal backplate. Initially the pedal pressure was the best I ever had after bleeding the brakes – but after driving 10km it quickly deteriorated. My guess was what after the caliper rebuild some pockets of air did not get out easily. Another brake bleeding session followed yesterday. This improved the pedal feel – but it is still not like it was at its best. Looks like the brake issue on the MGB will haunt me another weekend.

Leave a comment