KS Motortechnik finished skimming the cylinderhead on Wednesday. They also lapped the valve seats and cleaned the head. The thorough inspection concluded without any faults or issues. When I got the cylinderhead back the maroon color – which was the default for 18GB engines – was completely gone. Two coats of primer and three coats of maroon later it looked better than new. Michael gave me some 3M Scotch bride hand pads. These were perfect to clean the top of the engine block on Thursday evening – even though this took quite a while. Removing the deposits on the pistons was not easy and I could not get rid of all blacking on the surface.

To check if the piston rings are still ok I filled some fuel in each cylinder. They were all holding the fuel for more than 10 min – so I am confident that the piston rings are still in good shape. Somewhat surprising was the delivery of the new Payen AK660 head gasket. Usually it is black with some red and some enforced areas. The new one is green and looks a bit less promising. I will use it on the 18V582 engine but went with the one I got for Mildred’s engine.

One thing I had not considered was that the ARP bolts require a multi-toothed nut – which I did not have at hand in my garage. I ordered new ones but this meant I would not be able to finish the job until late Saturday. The waiting time was used to go shopping at Stahlwerk on Saturday morning. For the last few weeks I have been thinking about getting a welding machine. This weekend they had a 20% sale – now I couldn’t resist. The range of different welding machine huge and finding the right one can be hard. In the end I opted for the MIG MAG 200 St digital. It has a spot weld setting that I liked and a price point that was acceptable.

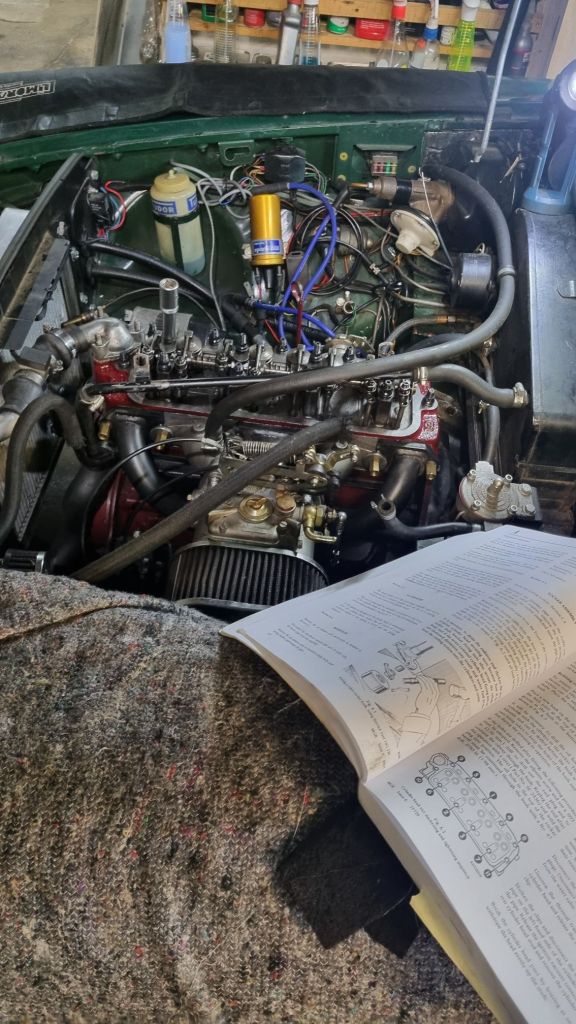

The shop was packed with people and I spent more than two hours at the Stahlwerk shop. When I got home in the afternoon the multitooth sockets I was waiting for just arrived. Back at the garage I immediately torqued down all eleven nuts in the correct order – followed by the 4 nuts of the rocker shaft. Next I check and corrected the valve clearance. New oil and coolant followed along with double checking all connections. With the ignition coil unplugged another compression test followed – just to double check my work. It also helps priming the oil pump.

But when I wanted to finally start the engine nothing happened. Any then I noticed that I cannot hear the fuel pump when I turn the ignition key. The Facet fuel pump is mounted to the side of the right battery box. Fortunately, it has a connector which makes checking if it gets 12v easy. As this was working I checked the earth connection and surprisingly this was the fault. The cable runs back into the boot and the ground cable is connected somewhere in the middle of the back valance. Where exactly was a good question. It was easy to recognize that the ring terminal had broken off – most likely when got my hiking stuff out of the car. I crimped on a new connector – found a screw with good earth – this fixed the fuel pump issue.

After this the engine started up right away. With the idle speed increased to 1500 RPM it warm up after a few minutes. It sounded ok – but not as good as before. The CSI Pro distributor has a Bluetooth interface and when the engine temperature reached 65° on the app (just about 80° water temperature) – I switched the car off. I decided to retorque the nuts to 50 ft-lb (68nm). A quarter turn and more was required on each nut – same when I check the 25ft-lb on the rockershaft nuts. Of course this meant that I need to check valve clearance again.

The test drive from Bonn to Altenahr via backroads on a sunny November day was a pure joy. The engine has its punch back – it is revving well. I stopped a few times to check for leaks. The heater valve as well as the elbow piece ontop of the cylinderhead had a few drips of coolant. I tightened the bolts and nuts and could not find anymore water 10km down the road.

Leave a comment