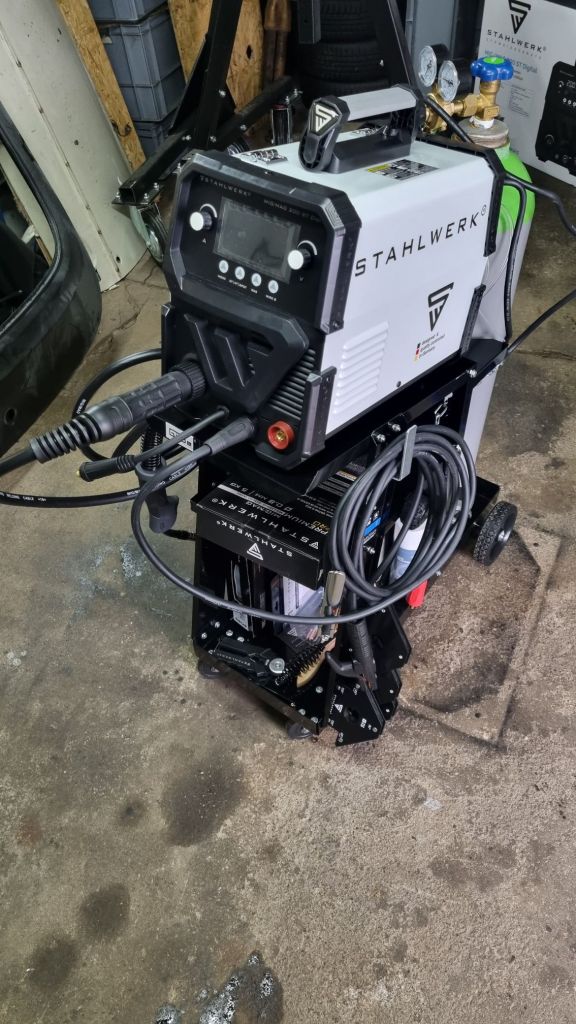

With just a few hours in the garage every week, it felt like I did not get much done in November. But looking back at the pictures I took – quite a few things happened. First was setting up my new welding machine. There is not too much to say about it. It does what it needs to do. A number of simple tests worked out quite well. One thing that I miss is an adjustable wire feed speed. I expected that this is possible to configure with the digital variant – but it does not seem to be possible.

Working with 2 and 3mm steel is really easy. Next I moved to 1mm sheet metal. Welding up smaller pieced of new metal works well – the spot-weld function is quite helpful once you got the right settings. A major downside is that after about 45min working time the main fuse for the power in the garage blows. The old cables running to my garage are most likely not sufficient. Not sure what to do about this. I only rented the garage – pulling new cables is not an option. If I only use the welding machine for short periods it seems to work fine.

On a dry weekend early in November I gave Sabbeth – my son’s Saab 900 Turbo – a very good clean-up. She has a bit of an engine issue recently. While there are no issue starting the car and doing city traffic. As soon as you do more than 80km/h she has a bit of powerloss and runs rough. This needs to be looked at and I promised to check this out next spring. In the meantime the best option is to store the Saab under the car-port spot I have and move Mildred’s orginial bodyshell into the garage.

While reorganizing the garage I also decided to change Miffi to winter tires, grease the suspension, check the brakes and fluids. With all this done, it was about time to focus on my engine test rig again. The wiring was semi-finished – I just still had to hook up all gauges and switches. Including drafting a diagram, cramping all connectors and testing all circuits this took two evenings. But this paid off as I so far did not encounter a single problem and everything worked right away. The main switch powers a relay which in turn power the Start button as well as switches for the coil, fuel pump and fan.

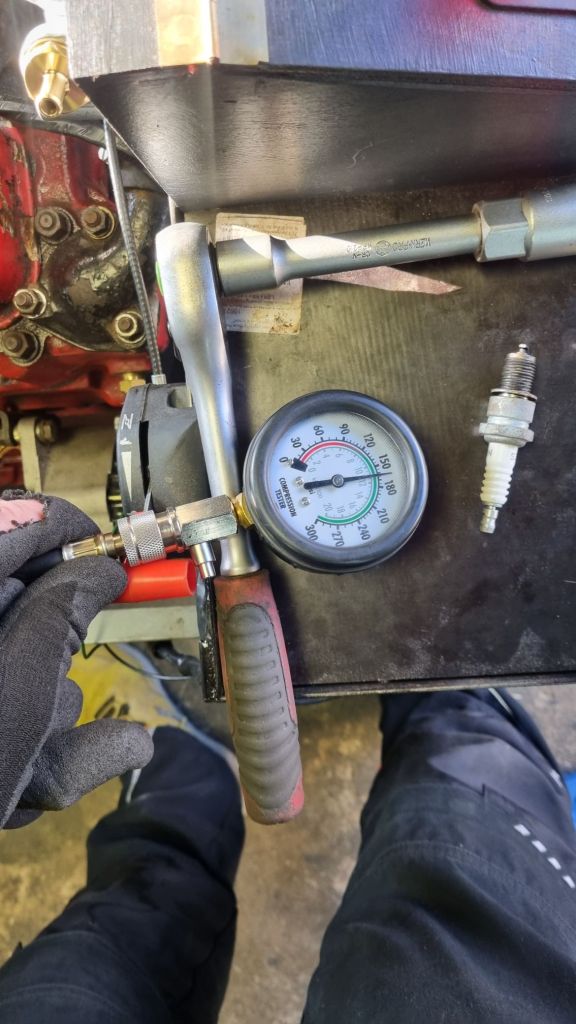

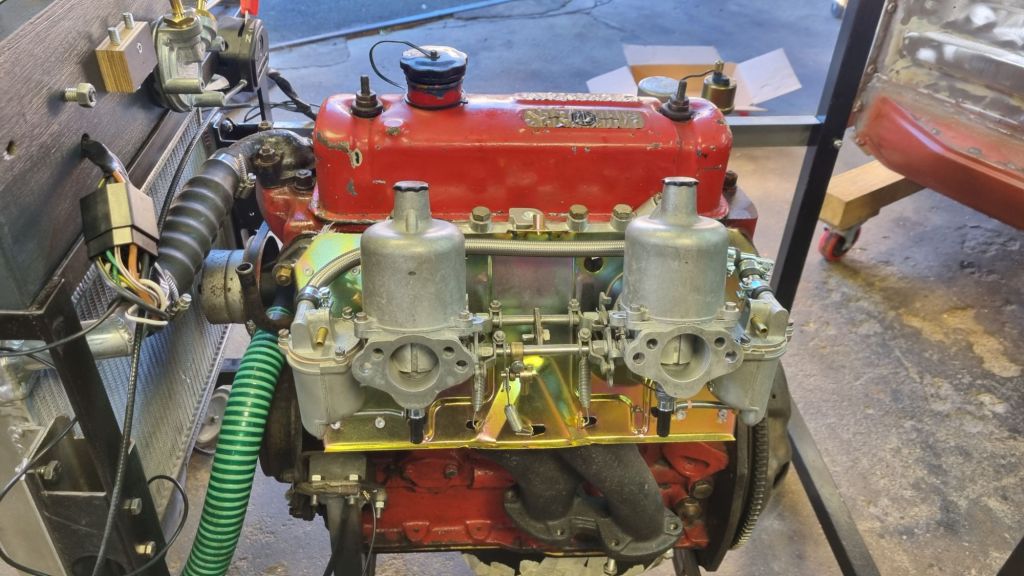

The mystery 18V582F engine I got from Frontline last year, was prepped with a cleaned oil sump. I checked the torque of the cylinder head and rocker shaft – which was good because somebody obvisouly had played around with it. Valve clearance was next on the list.As the engine did not run for at least one and a half years, I sprayed a tiny bit of oil in each piston. The new oil filter was also pre-filled. I turned the engine crank with a wrench on the main pulley a few times. The first test of my rig was to see of the starter can bring the oil pressure up. And sure enough – after a few turns the cheap China gauges will show perfect oil pressure. A compression test followed and all cylinders look good.

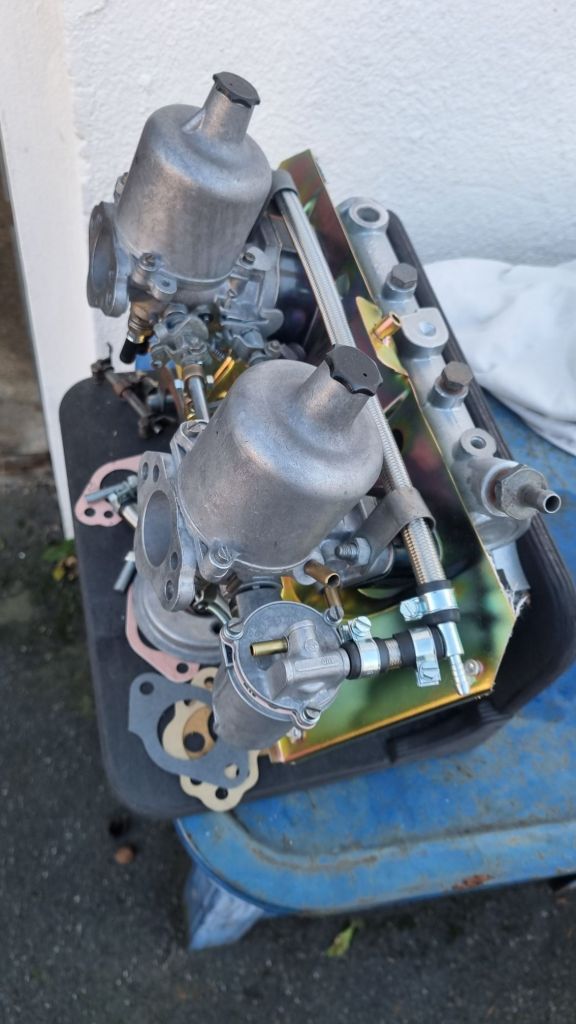

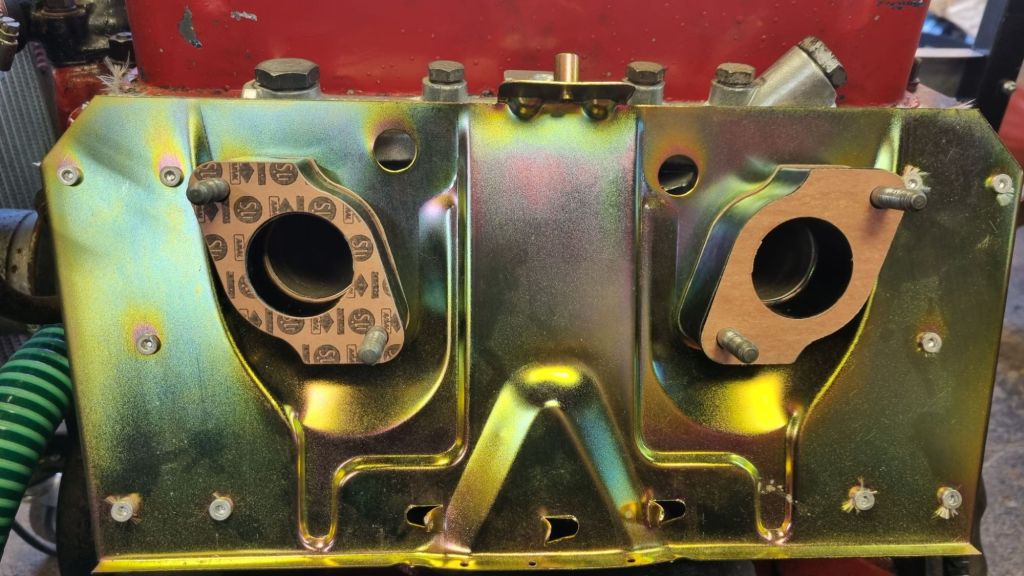

Last step was to install the HS4 carbs from Mildred. A Hardy fuel is mounted inside the control box I have built and I connected all lines to the SU carburettors. The vaccuum port on the inlet manifold for the brake servo was closed with a matching screw. I did the carb overhaul two years ago and could not remember all steps for the basic tuning – I leave this for tomorrow.

Leave a comment