After weeks away from the garage it was about time to prepare for the season. With nice weather forecasted – I wanted to get the Morgan ready. It got a complete check just before I parked it last November. Even though I disconnected the battery and charged it twice since – it was dead now and would not charge up again. A replacement just had to be picked up nearby. With this sorted and igintion on – I let the fuel pump prime the regulator and carburattor a for a few seconds – the engine fired up right away. For the first few minutes the exhaust was spitting out condensed water. Once the engine got to temperature that went away. Tire pressure also only had dropped very slightly. Cleaning the car in and out took most of my time in the morning.

In the afternoon it was time to focus on Miffi. Recently starting her had become a bit of an issue. It usually takes 6 or 7 tries to get the engine fired up. She has also started to lose some oil – which I just noticed on the garage floor recently after not driving the car for two weeks. In August 2024 I did a complete service to the Mini. All fluids were changed and a new alternator and belt fitted. The brake pedal has the sam issue that I previously had on the MGB. The hole that connects the brake master cylinder push rod via a pin was worn out. After welding the pedal and drilling out a new hole, I also ended up replacing the master brake cylinder. This was also a good time to add an additional engine stabilizer that connects from the pedal mount to the waterpump on the left side of the engine.

Back then I also tried fitting a Maniflow LCB – which I bought in the UK last summer. But the inlet and outlet flanges have different thicknesses. This caused some issues. Split washers are one option to address this. After two unsuccessful attempts with those to get the inlet manifold tight, I decided to keep the original manifold for now. Now – about 2500km later – I noticed that the lower exhaust pipe holder attached to the diff is missing – along with the screw. This is causing the oil leak from the diff cover. Obliviously I did not correctly tighten the screws. I did not have a spare 5/16″ one inch UNC bolt at hand and had to order it.

The rest of the service as easy sailing. After 7 years since the restoration – some small rust spots are showing up. Nothing too concerning, but they need to be addressed later this summer. For this I already had a chat with a company that is doing C02/ice blasting. Depending on the progress with project Mildred – I might also remove the engine and front subframe. Currently there is just a little surface rust. I tend to have the frame blasted and painted with raptor liner (or similar) this time.

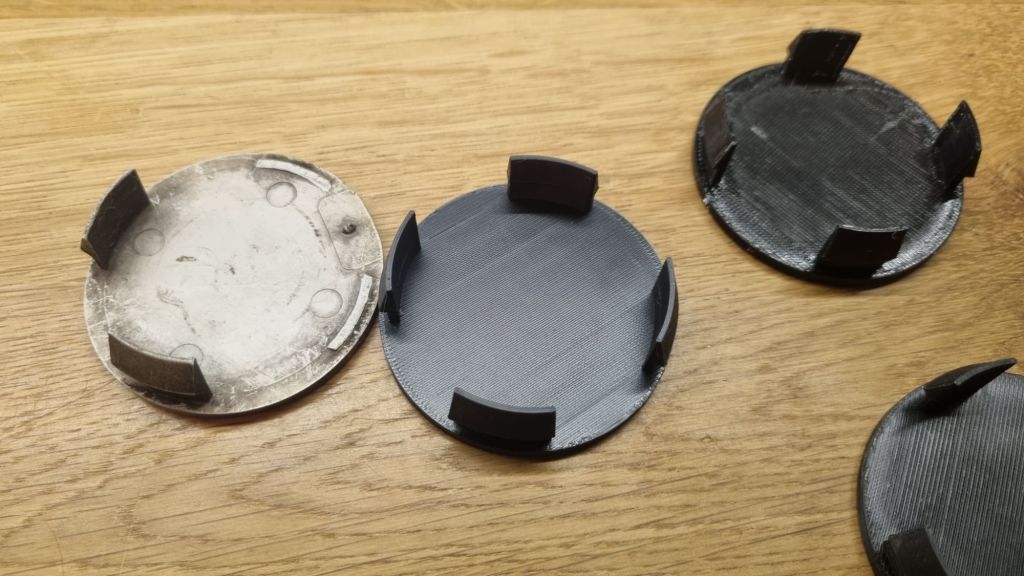

Last was to check the brake pads and grease the suspension. While doing this I came up with a plan to install the Brantz sensor on the rear wheel – but this will be project for another evening. Last step was to put the Yokohama summer tires back on Miffi. Like a few times before – two centre caps for the 12” alloys were broken. This little plastic piece costs a whooping 7.66 pound (!!!). Instead or ordering new ones, I decided to quickly drawn them in FreeCad and print them from PETG. Measuring and designing took less then 10 min – printing about 30min. Material cost 19cent. But I wasn’t satisfied with the surface finish. The Bambu Cool SuperTack plate does not leave a structure – but even with print setting set to Fine – some lines marks were visible. They can be sanded down easily – but the material is not really dark black – but rather grey (I will try painting these). As an alternative I tried the structure plate with TPU. These caps are slightly flexible and won’t break. Will check them on the Mini tomorrow and decided which variant wins 🙂

Leave a comment