Finally, after many months of waiting – the work on Mildred’s bodypanels has finally started. In just a few hours the old rotten boot floor, one outer floor extension and the front duct were fitted with new replacements parts. It paid off to get more expensive BMH panels and chop out the old ones entirely. This saved so many hours of work that this approach is financially more viable. In addition the end result is also much better. The difference between a professional with tons of experience and all proper tools at his disposal doing the job compared to a hobbiest is also worth pointing out. With the industry grade spot welder getting a new panels in is unbelievably quick when the preparation has been done properly.

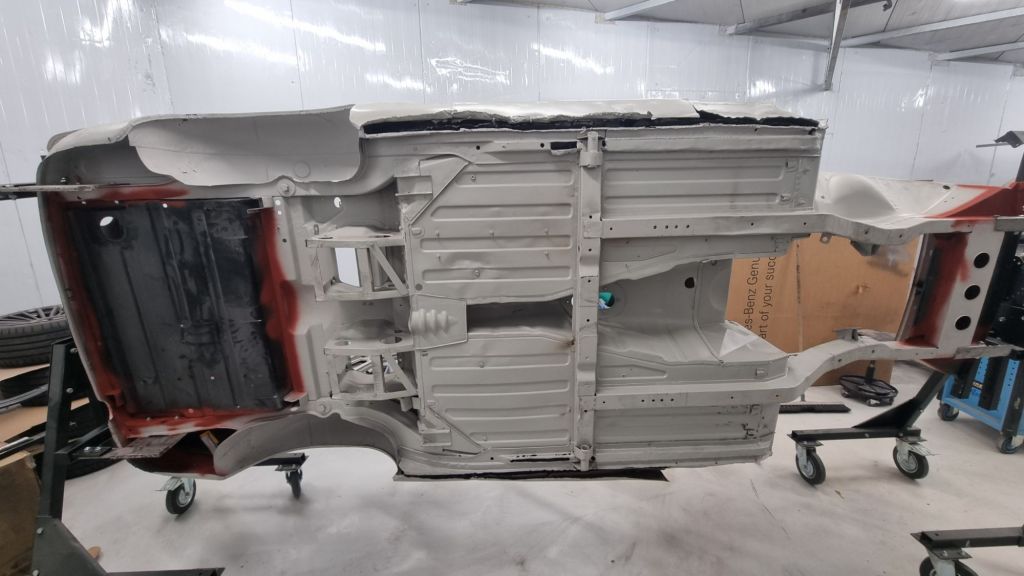

On Saturday I had to lift the shell on the roll-over jig I build. In combination with the chassis dolly this is quite easy and I have done this dozen of times now. The roll over jig makes the work that needw to follow much easier. Both sills and floors need to be replaced. But first the left inner wing reinforcement went in on Monday. This is an original BMH panel. And it turned out to be a surprise. Neither my 1967 GT nor any other shell I looked at so far featured a slot at the bottom of the panel – i was a bit unsure if this is right. We figured that it makes sense to allow water to escape – as this is an area where MGBs often start to rust. I posted a question in the german MGDC forum. There someone pointed out that the BMH video shows that new shells have a bulge in the innerwing – something older cars did not have. This leaves uncertainty on how to proceed with this corner.

The left hand outer sill, membrane, part of the crossmember and floor were also cut out. This revealed quite a bit of rust. Fortunately I already bought a complete BMH crossmember replacement. After some discussions and consideration we decided to replace it completely. The inner sill is quite rusted – but it is still structurally sound for the most part. We decided to repair a part – for the other side I will get a replacement panel – just in case.

Looking at further problematic areas we agreed that I also will buy a rear repair panel and outer wheel arch for the right side. The left rear side and wheel house just needs smaller repairs. The body shell was blasted and treated with primer a few years ago. But this left many places that were not derusted or cleaned. They only method to ensure more than 95% are properly derusted is a dipping the shell in chemicals following by a KTL (coating). And the bodyshop team says the right time for this is once all welding has been done.

This is going to be an expensive endeavour. Frankly, the entire rebuild/project is financially speaking outright stupid. Panels, welding, tools and KTL combined – buying a new bodyshell from BMH would have actually been better. Sure – also expensive but better. But stopping now also doesn’t makes any sense. Best outcome is to have a shell close to a replacement with all the modifications I want anyway.

Leave a comment