What started as a routine service on Maggie – my 1967 MGB GT – ended up in some unexpected findings and additional work. Approx 8000km after switching to the bolt-on wheels and axle with LSD (Mildred’s) early in 2024 – a complete maintenance job was due. For this I am following the tasks outlines in the Haynes MGB Owner’s Workshop Manual. With just over 40000km on the clock since rebuilding the car – it was time for complete list, slightly modified to adjust for the specifics of my car.

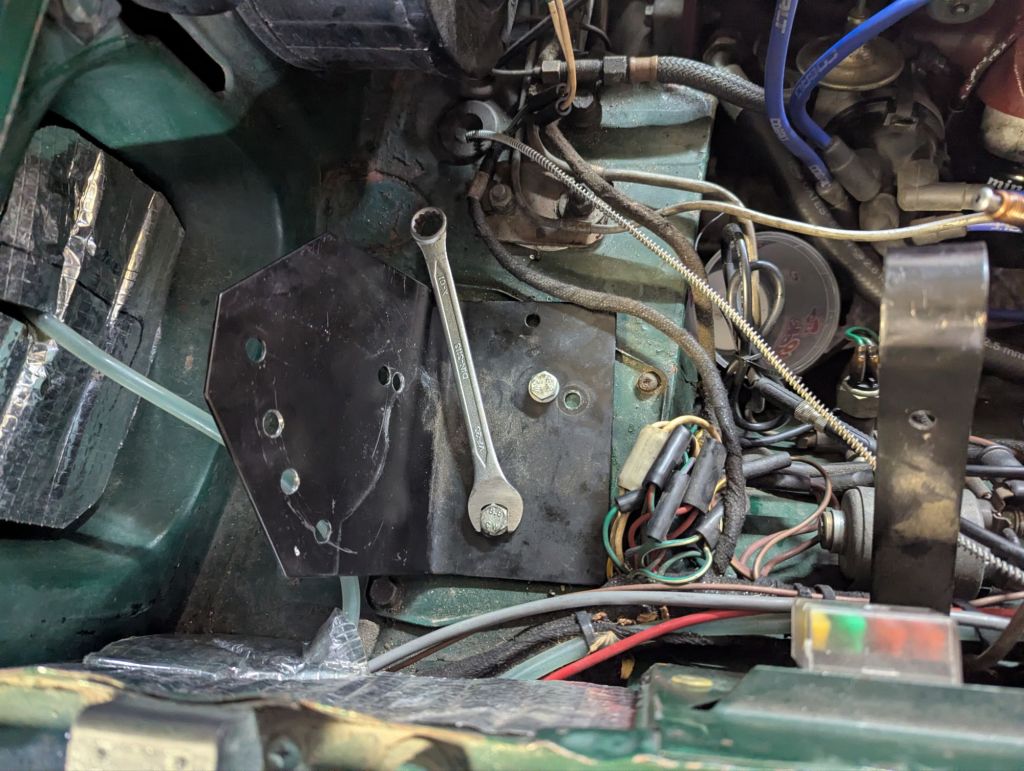

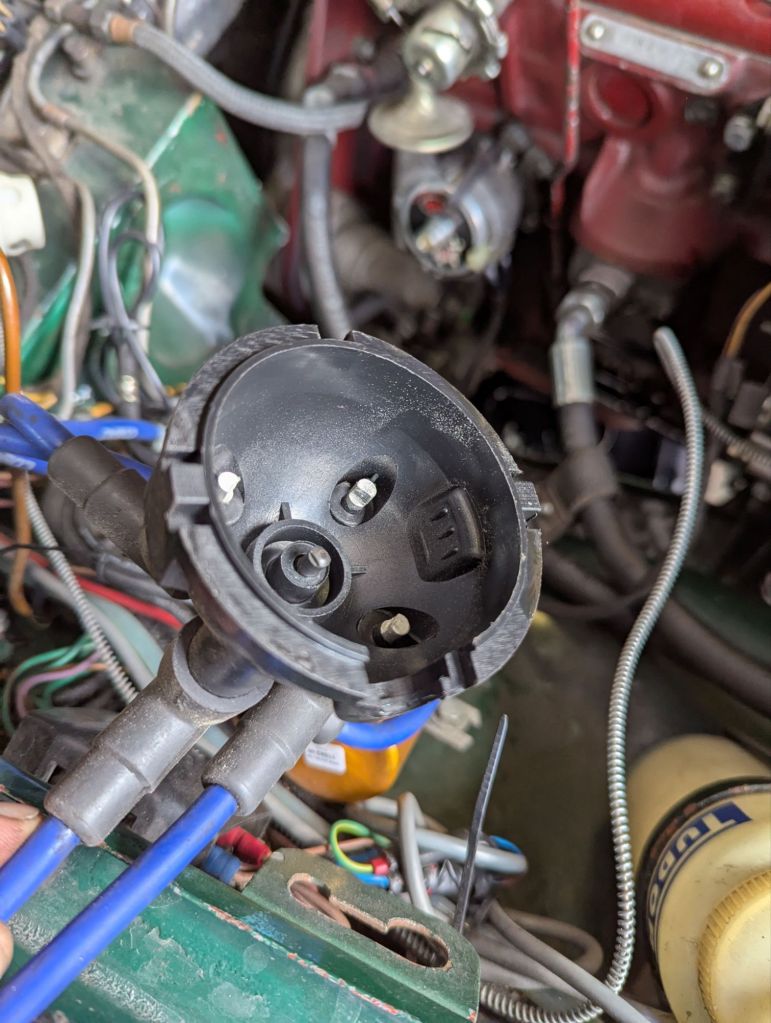

Having done quite a few services intervals on MGBs, Mini and Morgan over the last couple years now – the oil change, compression check and checking valce clearance and timing were all easy and quickky done. Greasing up suspension, hinges, universal joints and hand-brake cable is driven by muscle memory. As soon as I lifted the front of the car – I noticed that the one of rubber steering gaitor was completely torn. I have no idea when and how this happened. It is also hard to tell if this was caused by material weakness or a rough road (yes, Maggie saw a few gravel and forest roads last year).

When removing the trackrod and inspecting the rest of the suspension – I noticed that a lot of the new grease was pushed out on the right lower stub axle. These rubbers also have perished ever since the entire front suspension was rebuilt by Frontline back in 2018. With the parts at hand – the issue was rectified quickly. But this has to wait for a few weeks.

As I rebuild the old calipers and replaced the brake discs + pads last year – I did not expect any major issues. Well – when braking hard I noticed that the car is pulling a bit to the right. But I suspected that adjusting the rear brakes should take care of this. The rear brakes however looked good. A bit of dust but completely dry and the brake shoes almost looking new. The front brakes however revealed some problems. The right side was fine. Even wear on the pads. The left side however puzzled me after trying to get out the pads. It was impossible to remove the inner pad without undoing the caliper. And on asking myself why, I noticed that the disc is not setting centered within the groove of the caliper.

On the right side this was the case. I wondered if I could have installed the hub incorrectly. But even after swapping the two sides over – the problem remained. And while inspecting the brake disc – I saw that the Brembo disc installed just 3000km ago was blue on the inside. Something seriously went wrong. After digging thru forums and testing multiple different calipers, I came to the conclusion that this issue must derive from the stub axle rebuild. And sure enough – the same caliper is pretty much centered on the stub axle I have for Mildred.

I ordered 0.2mm and 0.5mm shim washers with 11 and 12mm internal diameter. With those placed between the stux axle and caliper, I was able to get the disk centered again after a few attempts. While doing this I also noticed that the rubber piston seal on my rebuilt Lockheed calipers had failed. This way the piston did not retract the same way. As I had to get the car back onto the road for various reasons, I opted to install the aftermarket calipers with the EbC Greenstuff pads – something I tested last year for a few weeks.

And sure enough, while the brakes really work quite well now, it takes a few minutes of driving before the old brake sequel issue is back. Anti squeal paste does not make a difference. I will need to investigate his further and will try mitigations – but due to other projects this has to wait. For now, Maggie is back on the roads with new TÜV. However, I do have to fix some rust problems that were criticized by the TÚV

Well done Tim great work as usual!! Simon

LikeLike