With Covid restrictions almost gone completely, my job requires a bit of travelling again. For a trip to office in Munich the fastest total trip time (door to door) is 3.5 hours for a flight and 6 hours when taking an ICE train. The average cost is between 350€ for the flight and 170€ to 300€(Flex ticket, 2nd class) for the train (with a Bahncard) – depending on when you book your travel.

The invite to Munich for this Tuesday to Thursday came late. Flight prices were far above the allowed company budget. Taking a fast train would have been within budget, but available times did not match with my appointments. And as my job limits my time in the garage and for my hobby significantly, I decided to make this business trip a journey in the MGB GT.

It also made sense (somehow). The travel time by car is like the railway option, The costs (1180km, 123,9l of SuperPlus fuel at 2,05€ = 254€) in the MGB are also in the same range as a flight or train. And the best part: I had the flexibility to visit a fellow MGB GT driver and buy an overhauled 4-speed gearbox including overdrive.

Some preparations were on my list before the trip. Task number one was to replace the throttle cable. The old one was “sticky”. The throttle did not return to the idle position correctly anymore and even a bit of lubrication didn’t help. As this is not an expensive item, I ordered a new one from Mr. Kischka in Cologne for my LHD 1967 car. It promptly arrived a day later. But as I have a Weber 45 on my car (which I forgot to mention) – I need a longer RHD throttle cable. Of course, I only realised this a few hours later close to 6pm. Another call to Mr. Kischka… I was more than surprised to receive the correct cable in my mail just after 8am. Excellent service from Mr. Kischka. Changing the cable only took 5 minutes and solved the problem.

Issue number two is something I mentioned before. There often (not always) is a rattling noise, when the car is running in idle. Carburettor and ignition were recently checked and tuned at Viktor Günther Motorsport. They also did an excellent job, and the engine runs well. Nevertheless, the engine often (not always) shakes quite bit on idle. This in turn causes the hose that is fixed to the valve cover and connects to the heater, to transfer the movement to the heater matrix.

For some reason I thought it would be a promising idea to install an additional engine steady. There aren’t many aftermarket options of the MGB, but Peter May Engineering offers one. In theory it should be easy to install – at least on the RHD car. The base gets mounted in the already drilled holes for the LHD lower steering bracket (AHH6311 on my car). A bracket that gets screwed on at the upper rear part of the B-series engine block will then connect the steady from the base with a rose joint.

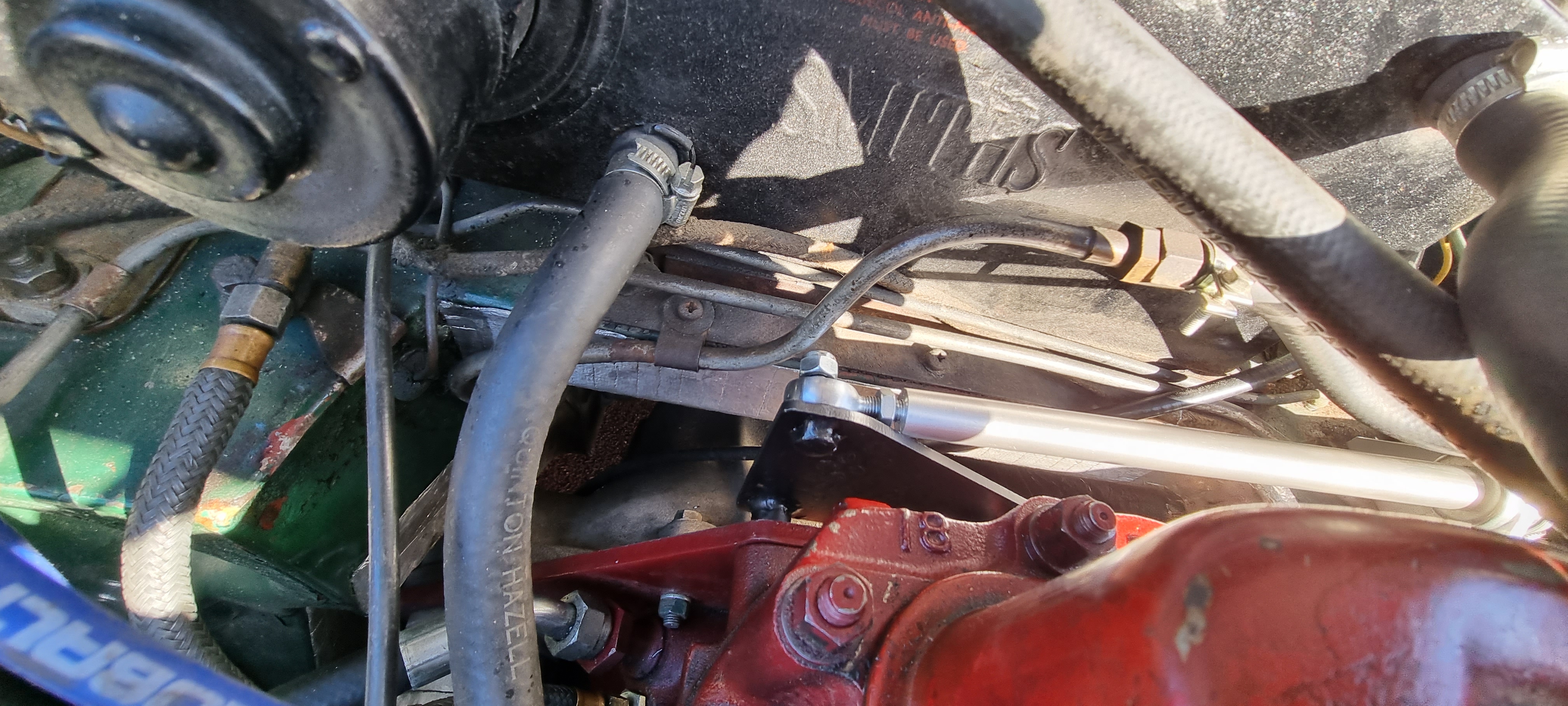

When trying to install it however I ran into issues. The bracket I received however look like somebody welded on the bolt on the wrong side. It is exactly mirrored from the pictures on the website. At that point I also started to dislike the idea, that the base of the steady is attached to the steering bracket – after all I have a LHD car. Flipping it over to the RHD would be an option, but the hose for the oil pressure gauge, brake line and the fuel line interfere slightly. So, in the end it would be everything else but an easy install. For now, the bracket will stay on the shelf – when the time comes to assemble Mildred, I will make sure it fits. And the easiest fix is to slightly increase the idle speed – this eliminates the shaking immediately.

Even without having opened the heater box, it is safe to assume that the foam around the matrix has perished most likely a decade ago. A few months, back I bought two used spare heater units which needs to be restored. Looks like it is time to give this task priority in my ToDo list.

The drive to Munich was great and on Thursday I met with Andreas (who commented a few times here in the forum) to pick up a gearbox. We only exchanged messages in forums, emails and here so far – it was great to meet him personally. His original white MGB V8 (converted to LHD) looks really nice and has an awesome sound – especially because it is not too loud. In addition to the gearbox, he gave me quite a few other spare parts – all of them will come to good use.

Just before I left, Andreas looked at the A-posts on my car. He instantly cut a pieced of 1,5mm diameter clear PVC hose to length and pressed into the groove on the windscreen. This should help to reduce the wind noise – and it is noticeable on smaller roads.. The problem with my car is that engine and exhaust are too loud when driving 130km/h(+)…. and this is what I did most of the time on my way back. The actual drive time back home took 5:45h. (7.5 hours including breaks I made of phone & video calls). It could have been much faster if I would have sticked to the Autobahn – but I did almost 100km´on backroads to make the trip more enjoyable.

Finishing the brakes lines on the Morgan was my plan and wish for this weekend. After some unsuccessful tries to get help in garages close by, the decision to build my own brake lines was heavily influenced by a recent SuperFast Matt’s video. His projects and Youtube channel are awesome – the combination of knowledge, skills and humor is outstanding. And frankly, even though the flaring tool he uses is expensive – his arguments not to save on tools made me order it after some going back and forth.

Unfortunately, the ordered OJD Quickbrake lines did not show up. These Cunifer lines have an “ABE” – an important certificate needed to the German TÜV. As this would be my first attempted with brake lines, I ordered 25feet of noname Cunifer brake line from Amazon – just to save my weekend – and those were delivered today.

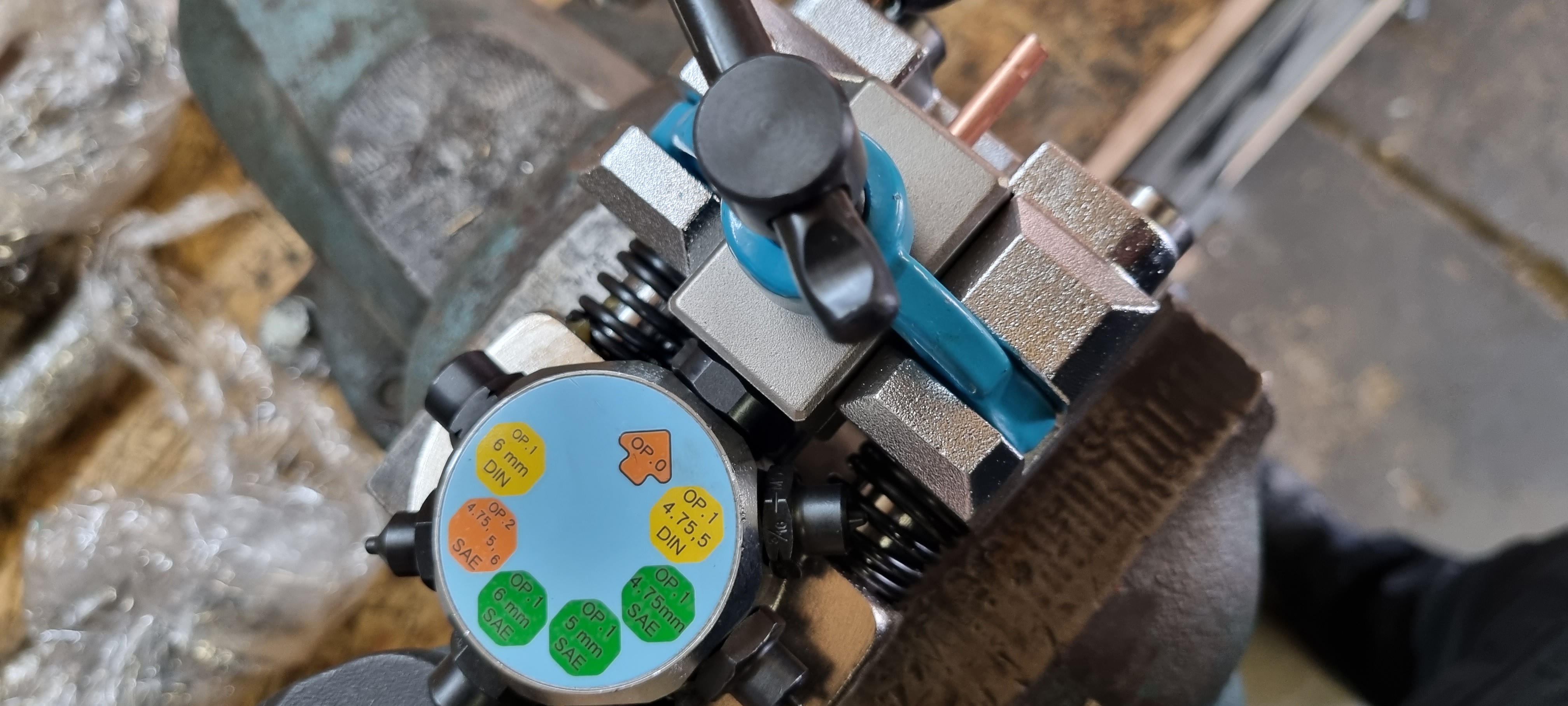

Bending the pipe to the form of the old one was not as hard as I thought. As the flaring tool needs approx. 5 cm of straight brake pipe to do the flare – it was clear that the ends with the nuts on need to bend as last step. I started on the left side and used duct tape to attach both lines. Then I followed the shape and taped sections by section to the old brake pipe when the form fitted. Once I was satisfied with the shape, I cut the pipe to length and deburred the ends. The flaring tool is for sure worth it’s money. I did my first flare on a 5cm cut-off. The steps (operations) 0, 1 and 2 are marked on the tool and the result looks perfect. The only downside: I ran out of time to get the line installed on the Morgan’s back axle today…

Hi Tim,

it was a real pleasure to habving had the opportunity meeting you in person :-). Just 2 comments: I still guess that your ‘rattling noise’ at idle is due to your too hard or even racing type engine mountings. I had the same issue time ago and the problem has been easily solved with ‘best quality’ normal/soft mountings.

As we use our GT mainly for long distance traveling and ‘cruising’ finding/ fitting a proper exhaust was a real issue. Especially as I typically don’t like (a) the sound of stainless steel systems (b) noisy ones. Mild steel had been my choice over the years and after the ‘original’ sysetems no longer available I went for a PECO. Sound was ok, but quite loud. Thereafter the choice was the 2 silencer version from Manifold, which was the best solution ever. Fitting, sound – excellent :-).

However I have to admit that after/ due to Brexit the customer realtionship to Maniflow became very much an issue. The system I ordered last year did not fit at all :-(. Also an ‘exchange’ of the wrong parts could not be materialised. In the end I went for a ‘mass taylored’ ss system which has been done by the counterpart of AS in GB. Fitting and sound excellent and a true ‘Grand Tourismo’ combination. Which will be complemeted after the 2022 season by Clive Wheatley manifolds.

Good luck for your body related ‘works’.

All the very best Andreas

LikeLike

Hi Andreas. I forgot to write about your suggestion to replace the engine mounts. The ones in Maggie are the uprated ones from Moss: https://www.moss-europe.co.uk/mounting-engine-rh-mgs10763r.html?assoc=109870

I am not entirely sure if uprated means harder, but mostly like it does.

Changing the mounts is certainly an idea, but certainly not a task I am looking forward to in the next couple weeks.

When it comes to the exhaust system – I will certainly do something about it in the other two GTs I am restoring. For normal weekend tours and day trips the Tourist Trophy system in Maggie is pretty nice. Today, I drove 300km to Amsterdam and below 130km/h (the max. speed in the Netherlands) I like the sound actually quite a bit.

Talking of sound: on this trip I also noticed the positive effect of the pipes you installed on my car. The wind noise is much lower. Thanks again for this.

Regards

Tim

LikeLike

Hi Tim,

please have a look to the Moss page. You will find the clear statement: for competition use. As you are not going for track days – at least as of today – the milder version will most probably solve the ’shaking‘ of your engine especially on idle.

The pipes really work :-), 🙂

All the best Andreas

PS and thanks again for your help in electrics – everything is now working fine

LikeLike