Receiving the endoscope pictures, including the assumption that a piston might be damaged, was a bit of a downer earlier this week. Going through the options I told myself that I can pull the engine and swap in the 18V engine I have. With this plan in mind, I borrowed a trailer today and drove up to Cologne to bring Maggie back home. When I arrived Gerhard already greeted me with good news. A better endoscope revealed that there were just carbon deposits – no sign of a hole. And because Andreas P. – well known for is understanding work as editor of the German “MG Kurier” magazine – was also around, the decision was made to inspect the cylinder head together.

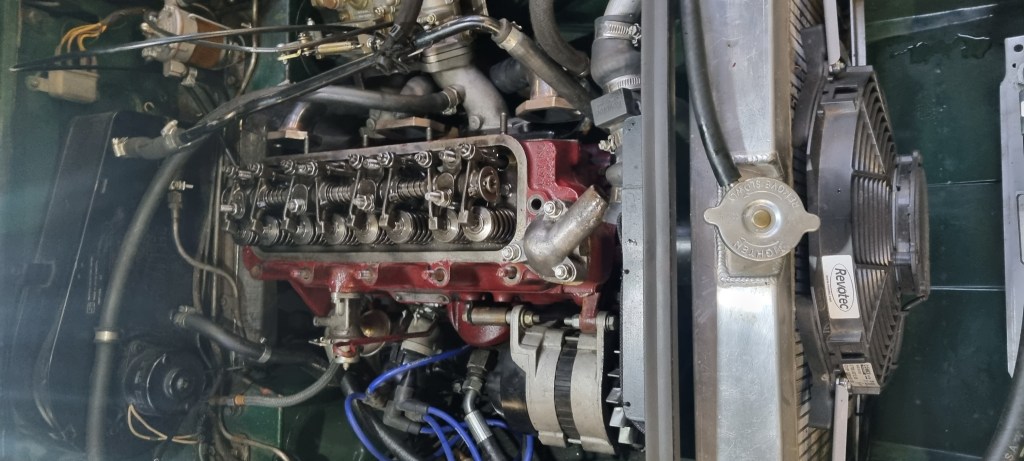

GB Classic has a fabulous new workshop. Plenty of space, well insulated, excellent tools – certainly a much better place to work on cars compared to my back yard garage. It was quickly obvious that Andreas has done this job numerous times before. I tried to assist as much as possible and followed his guidance. After flushing out the coolant, Andreas removed everything on the right side of the engine, while I took care of the exhaust and inlet manifold. First thing we noticed is that about half of the head studs came off with the nuts. This is not optimal and should not happen – but it is also not the end of the world. When I need to remove studs in my garage, I always use a counter nut. In a professional garage a stud removal tool makes this task a lot easier. Something I don’t have in my tool collection yet.

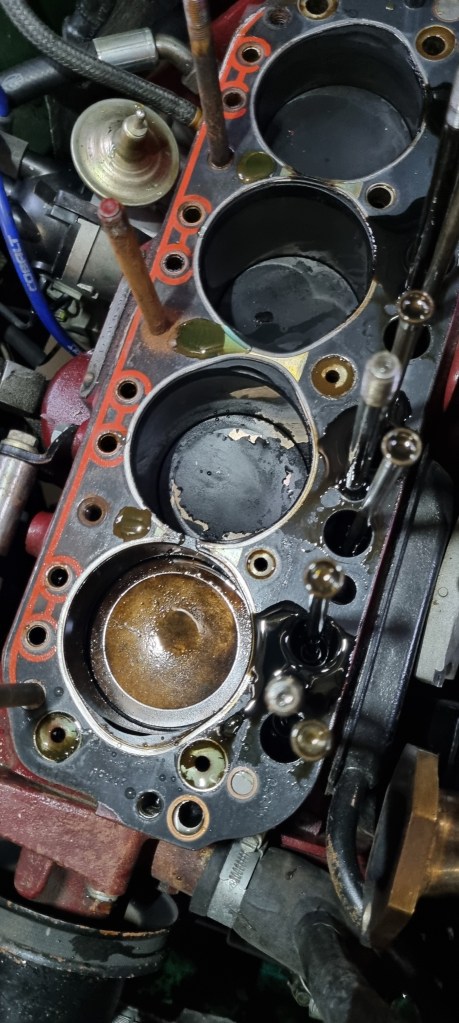

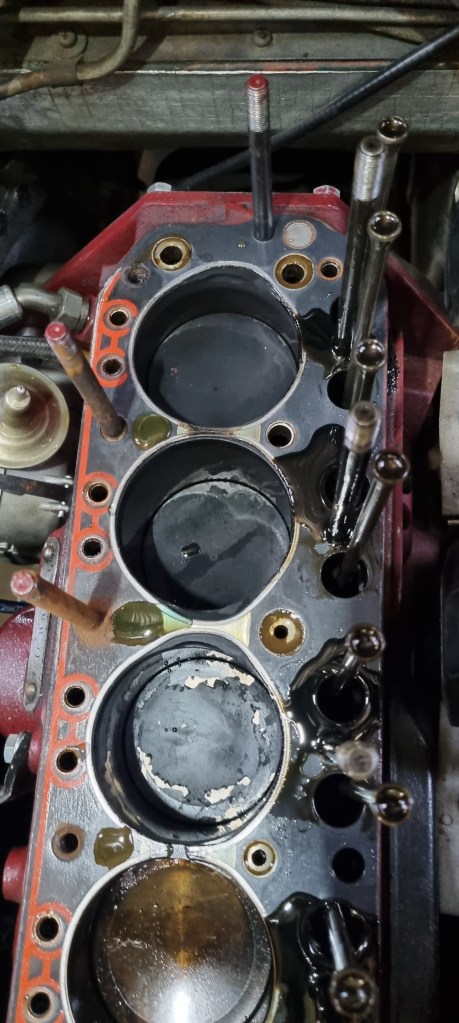

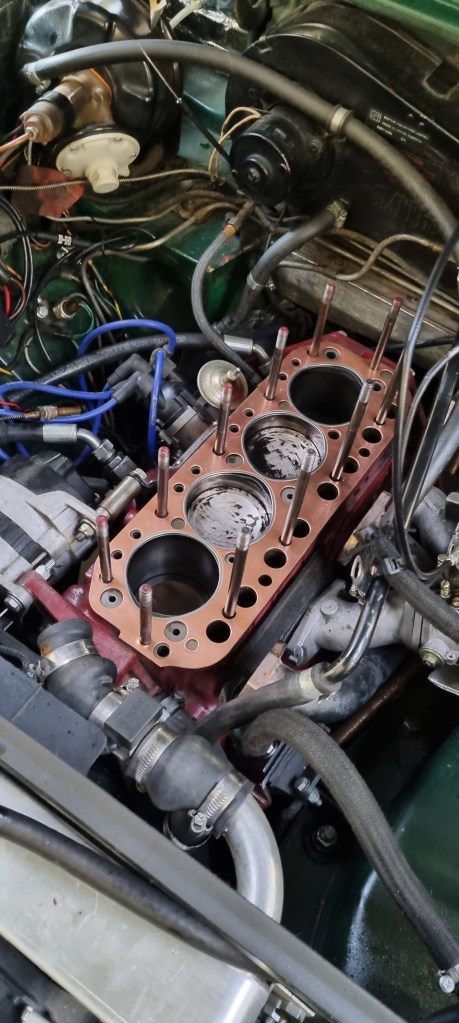

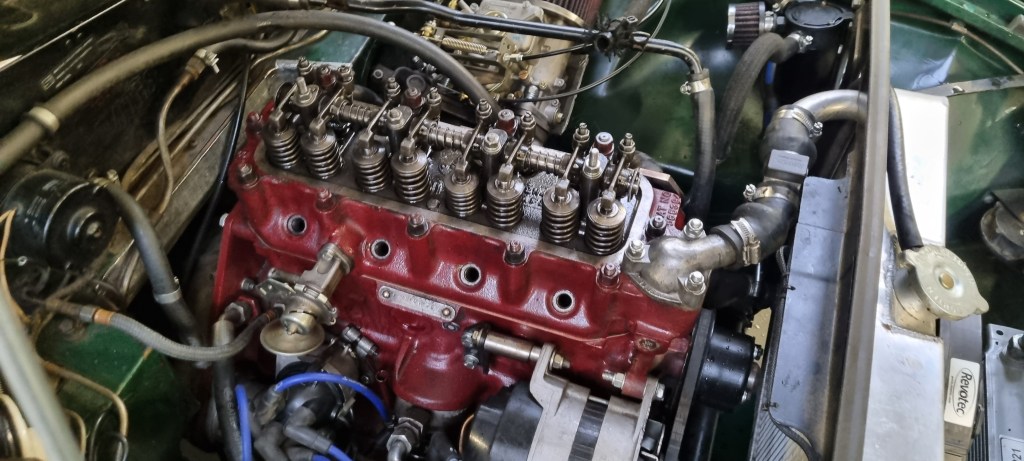

The removal of the cylinder head did not take long and revealed the issue – a blown head gasket. It made sense to remove the remaining studs to allow easier cleaning of the engine block surface with fine sandpaper. We also tried to remove as much of the deposits from the pistons. While Andreas cleaned the block and fitted the bolts again, I cleaned the cylinder head. As this entire action came a but unexpected, I didn’t bring one of the Payen or BGA HK1307 (recommended by Frontline) gaskets that I already ordered. Gerhard had a standard cooper head gasket available – not my first choice, but it will do for now. Initially we tried to leave the rocker assembly in place – but had to take it off to slide the head onto the block.

After tightening all head nuts to the correct torque specs, Andreas took care of the rocker assembly and valve clearance – while I battled with putting on the exhaust and inlet manifold back im place. After connecting all hoses, the heater valve control cable and temperature sensor all that was left was to fill up new coolant. A compression showed 13bar+ on all cylinders. After letting the engine warm up for a few minutes, we did a short test drive which went well.

We believe that the blown gasket between cylinder 1 and 2 (the bridge between 3 and 4 also looked bad) was caused by either running to lean and/or incorrect distributor timing. This can cause the head to overheat – resulting in the issues I had. Both the Weber and the CSI distributor were tuned at a professional garage earlier this year. As this is likely the root cause, I need to address this issue next – otherwise it is just a question of time until the problem comes up again.

Professional help does not come for free, but I am glad I invested the money for a few hours this afternoon to get Maggie back on the road. It was a blast to work with Andreas and Gerhard and I gained confidence to do this job myself next time if needed. If you are looking for a good garage for British cars in the Cologne/Bonn area – GB Classics is my recommendation.

…and do not forget about ARP studs next time :-). I would also go for the Payen

Kind regards Andreas

LikeLike

Following your earlier recommendation, I already have a set of ARP bolts here already. As I wrote – I did not expect the quick head gasket change we did last week – so I neither had a better gasket not the studs with me. As you can see on the pictures, Maggie’s engine did have a Payen AK660 that burned through.

I am curios how long the standard cooper one will stack up.

LikeLike