Why did it take so long to finish this job? The MGB rear axle overhaul – Part 1 – disassembly is one off the most viewed articles I wrote with a couple hundred views. Maybe this is reason why I had the axles back on my bench a couple times but there was always something that caused me to not finish them. Well, maybe because the rear axle for Mildred is not super urgent – the body shell is still sitting in the second part of my garage. The car body-shop I am working with is extending their space. This was supposed to be done by the end of September – by the looks of it I don’t expect that they start on Mildred in 2023 anymore. I should start looking for an alternative perhaps?! Or start to learn how to weld and do it myself.

The reason I finally got around (more or less) finishing both rear axles is Maggie – my 67 MGB GT. During the driver training I had the impression that the rear suspension could be better. The leaf spring bushes have seen better days and I wanted to replace those with Poly for a long time anyway. The axle had two oil changes in the last 6 years. Both time I had a few particles in the oil. Combined with a bit of clunking that got louder recently – I assume that the thrust washers are either worn or gone.

With Mildred not getting closer to assembly, it just makes sense to replace the axle with the spare one I have. And while I am at it – I plan to upgrade Maggie with the Mazda 5-speed gearbox, the Fidanza Flywheel and new Dunlop wheels. There are a few other things I need to do before – but I hope to start with this by January 2024. In the meantime, I wanted to get the axles complete and off my workbench.

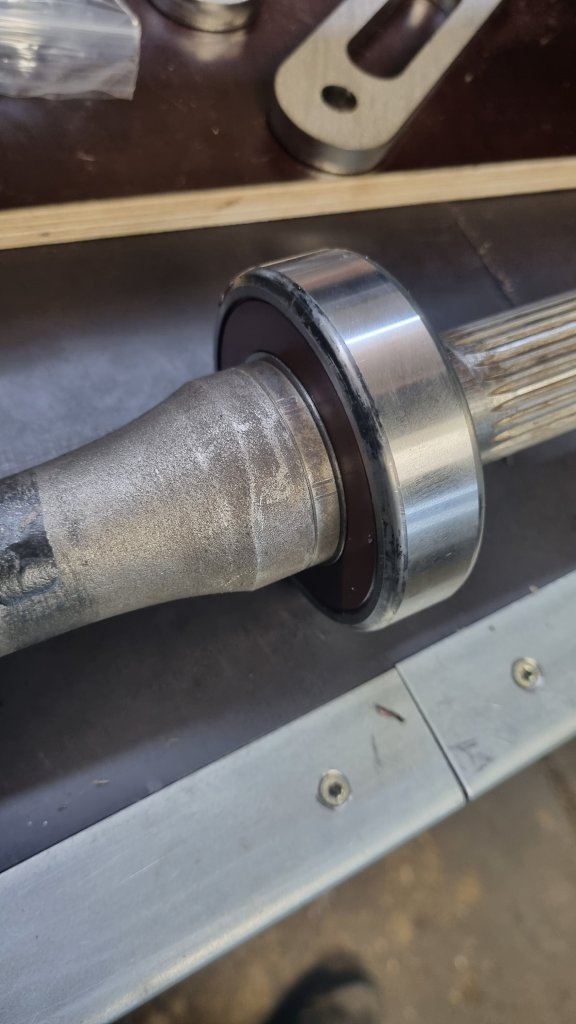

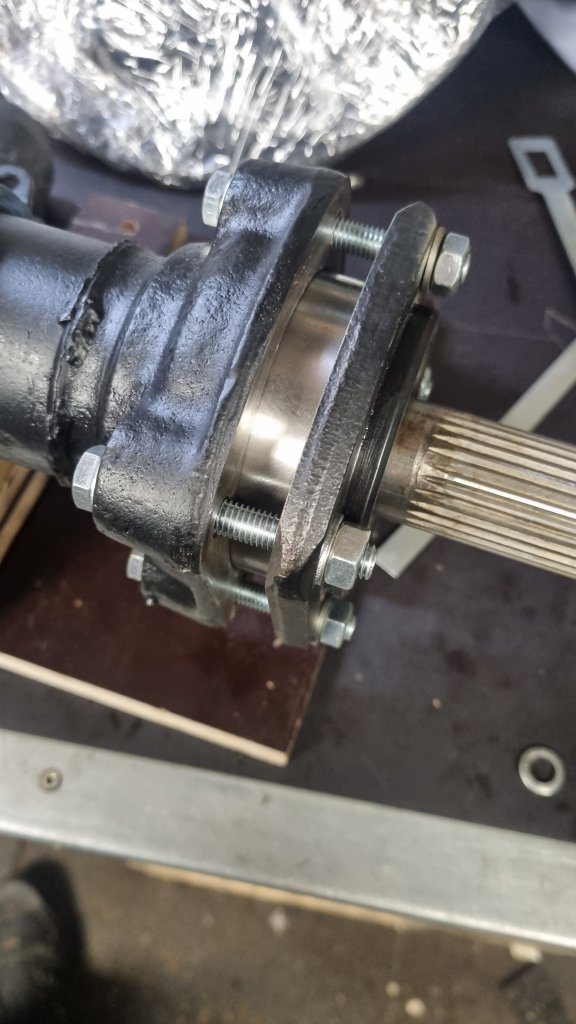

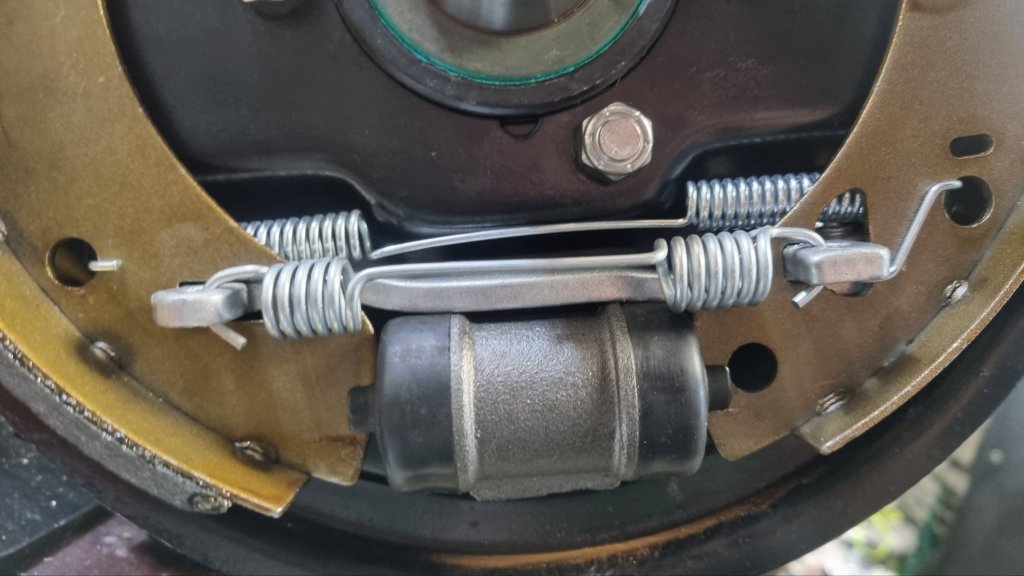

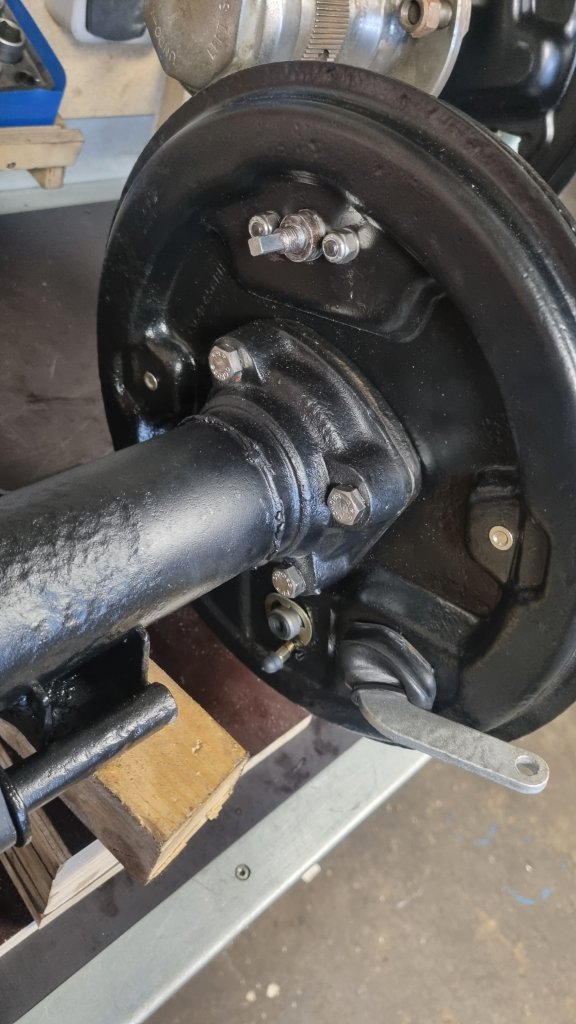

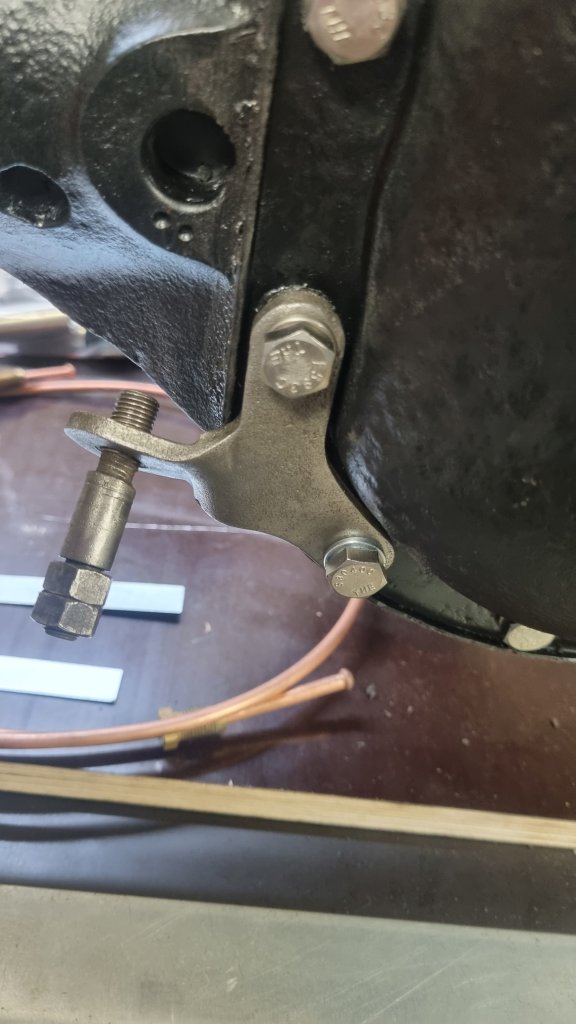

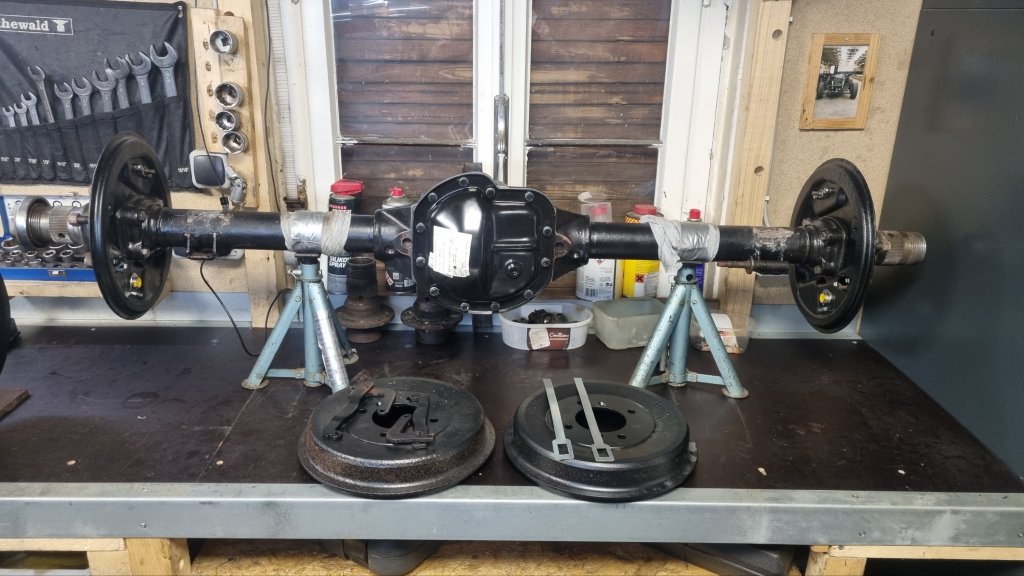

The shiny powder-coated one with the Blackline LSD I got back from Hardy just needs drive shafts. For those I got the sealed RHP bearings. Having seal bearings might be overkill – but then again, why not use them? Putting this axle back together was straight forward. The brake parts had been powder-coated quite some time ago. I also had two new rear brake cylinders sets in storage as well as most other parts.

The second rear axle is Mildred’s original axle. Replacing the old drive-shaft bearings might have not been necessary – but I did anyway while I am at it. Pulling the old bearings was easy but pressing the new ones onto the shaft was done at Stephans workshop – a decent press makes this job a lot easier. An old outer race of a Mini Cooper front wheel bearing perfectly fits to press in the oil seal on the MGB axle and a bench vise is all you need for this.

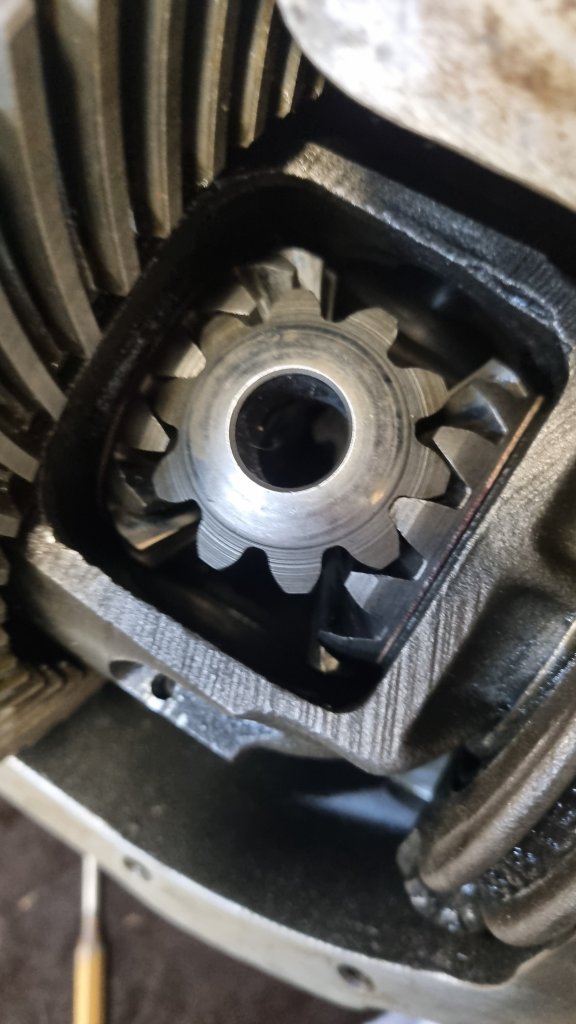

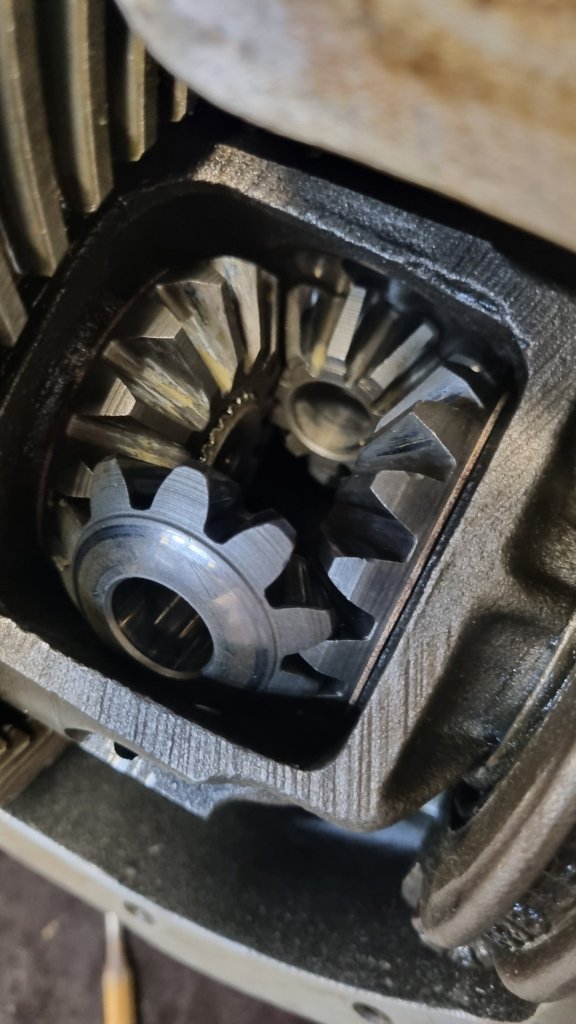

After one shaft is back in – the small gears attach to the shafts need to be put back in place. The recent video below from John Twist shows this to some extend – there are also a few other examples out there on Youtube. The standard flat thrust washers for the gears on the drive shaft are made from a fabric material. I also got brass washer – but with those I could not get the curved cooper washer on the smaller gears in place. It was just too tight. My recommendation: only partly insert one shaft until you have all gears in place. Buy both washer types if possible. The brass ones are slightly thicker – there should not be any free play in the gears. Test those first. On my axle the thinner fabric washers worked best.

On the bench this job is quite easy – if you have done it once it is certainly possible to do it with the axle in the car – just a bit uncomfortable if the car is just on jack-stands. My recommendation: If you plan to upgrade your suspension – get the axle out, clean it and do the job on the bench. If you just want to “de-clunk” your axle – leave it installed.

An additional set of brake shoes as well as a couple other parts had to be ordered from Rimmerbros. While I am waiting for this, I need to get the coating of from the insight of one pair of drums. I did not notice that the powder-coater did not protect the insight face as he usually does. There are also quite a few parts that need cleaning and zinc-plating.