The recent lack of news here has a few causes – but it certainly does not mean that I lost interest or abandoned the plan to restore project Mildred. After our vacation I only had a few hours that I could spend in the garage. And quite a bit of this went into cleaning and servicing the Morgan. Our vacation trip resulted in 4000km and the Morgan sliding pillar front suspension should be greased regularly. This was the easy part – an entire evening was spent checking and re-fasting all bolts, nuts and screws of the chassis and bodywork. Approx. 40 per side had to be checked and after the trip almost all of them were not as tight as I would want them to be.

A larger shelf on the left side of the garage for all fluids was on my backlog for a while. It is not completely finished but good enough for now – more on this at a later point. After a sweep and bench cleanup it was time to move Mildred. About three years ago I bought this nightmare of a MGB GT because I thought that the Morgan would soon be finished. And since Dec 2021 I am waiting that the required welding and body-work will start.

After further delays earlier this year I wonder if the anticipated move in July this year will really happen. In any case I am still preparing for this by making sure to have most if not all repair panels at hand. Both sills need to be redone including the castle rails. I got these early during a MGOC sale in 2022. New floors and a crossmember found their space on the parts rack shortly after. The entire boot floor, the left side A-pillar and new door skins arrived last summer (when I thought the work would begin)

This week the inner doors frames, the tail-gate(s) and bonnet I worked on two month ago came back from cataphoretic dip painting (KTL). This was somewhat expensive, but the most durable protection possible. The original tailgate skin was gone and I stripped the metal off a long time ago. As the tail-gate skin was not available last year (it is now) I also got a second one that looked ok on first glimpse. But the KTL treatment will expose all rust issues. Now I am unsure what is more cost effective – repairing the problem section on the second-hand tailgate or getting a new skin.

Once all body work is done, it might be the right time to do a KTL protection of the entire body. Major issue here is costs. It is extremely expensive. But it also almost entirely eliminates future rust issues – especially when combined with a wax cavity sealing. As Mildred is now intend to become a daily driver – it might be the right investment. I need to think about this a while.

While Milred is gone I intend to build the new wiring harness. The main difference to the original will be the addition of relays and additional fuses. The dashboard will also be completely prewired and connected via a multiconnector to the rest of the loom. This should reduce under-dashboard-yoga-sessions to a minimum – just the fun installation of heater controls, choke and the combined Oil-pressure/temp gauge will remain.

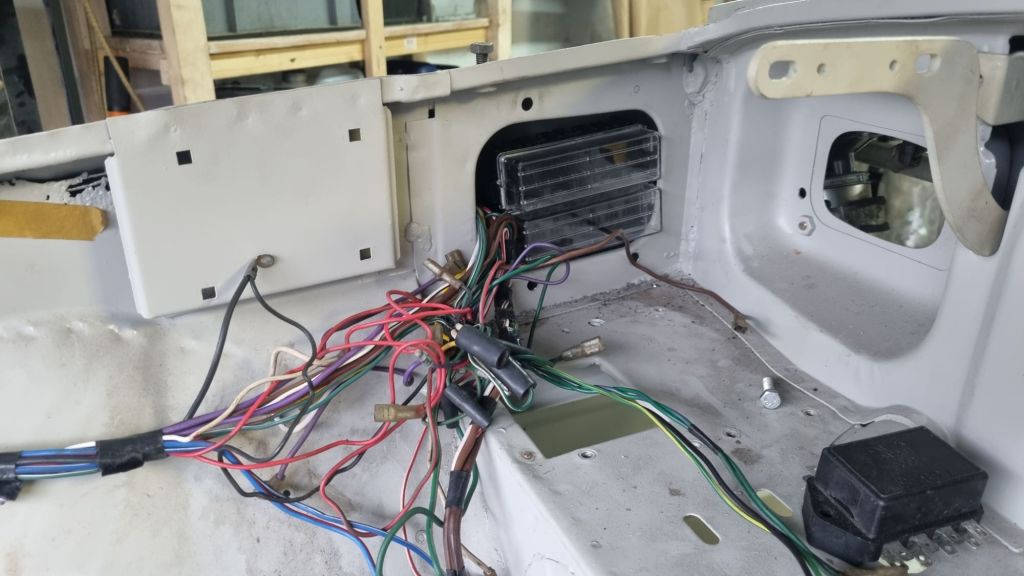

For most of the upgrades – and the list is quite long – an extra loom will be added. I believe that this will make potential trouble shooting a lot easier. PowerSteering, electric windows, heated seats, heated front and rear screen, additional lighting, central locking and USB charging ports will all benefit from additional fuses. The idea was to also place the MTA fuse and relay holder behind the dashboard – similar like I did on the Morgan.

A test installation of the wiper motor and dashboard revealed a problem with this idea. Without the paper glove-box it would work – but once that is installed the fuses are note really accessable. When moving it further to the center the console will block good access. Next idea was to develop (maybe 3d print) and insert for the cavity on the right side of engine-bay (as seen below). There are a few benefits of this location. The wiring harness routes through this hole anyway. It has a somewhat better accessibility and does not look too bad. Downside of this solution is: I can only fit two modules – 16 fuses and 7 micro relays. This might not be enough.

A possible (and currently most likely) alternative is the passenger (right hand) foot-well. There is enough room to fit four modules. For example 32 fuses and up to 14 micro relays – or 7 micro and 4 standard relays. This is right below the hole where thie wiring harness is routed into the engine bay – underneath the wiper motor. Major downside – who would want a lumpy plastic box visible in the foot-well? There is more than enough space behind the front wing. My preferred solution right now is a box added in this space with a cover accessible from the foot-well. But the final decision has not been made.

Perhaps wise to have the electical and fuse box inside the car and thus out of the way of weather???

LikeLike

I agree. Will proceed with the passenger footwell location – more on this in a few days

LikeLiked by 1 person