Project Mildred (my 1973 MGB GT) is a good example that rust removal and bodywork is the most time consuming and cost intensive parts in a restoration. For a long time I often thought that it would be nice if I would be able to do at least some of the metal work and welding. But how and where to get started with this?

A few years back I attended a one da welding workshop from Linde. The majority of was safety and theoretical class room information – with about 12 participants and only three hours of practical time – I cannot say that it helped a lot. Even worse was the “sales” part at the end of the day, which left the impression that a few thousand euros need to be spent on the right equipment.

The few welding attempts that followed were all not great. This is mostly due the car to that I was not super comfortable with the welder, did not practice on test pieces beforehand and felt rushed to get the job done. This combined does not result in good welds and does not build confidence. It was time to change this. A few weeks back I found the workshop offerings at MP’s Classics in Cologne. This sounded much more hands-on and decided to try this out last weekend. The course with four participants started Saturday morning at 9am. After a friendly and nice welcome by the owner Markus, our trainer Uwe gave us a short safety introduction. After a brief explanation and overview of tools and equipment we went to the hands-on part straight away.

We split up in two teams and everyone of us was able to close to hundred test welds on 0.8mm thin metal. In the beginning I worked with the Stahlwerk MIG/MAG 200 ST IGBT welder – which was the slightly more powerful station. Uwe suggested the Amp&Volt settings – but encourged us to test different settings. After the first tests with overlapping pieces, we used the edge setter and hole punch pliers. Uwe recommended to use this method whenever possible – especially for beginners. After a few attempts I got the hang out of it. After lunch only two participants that only booked the C1 course left.

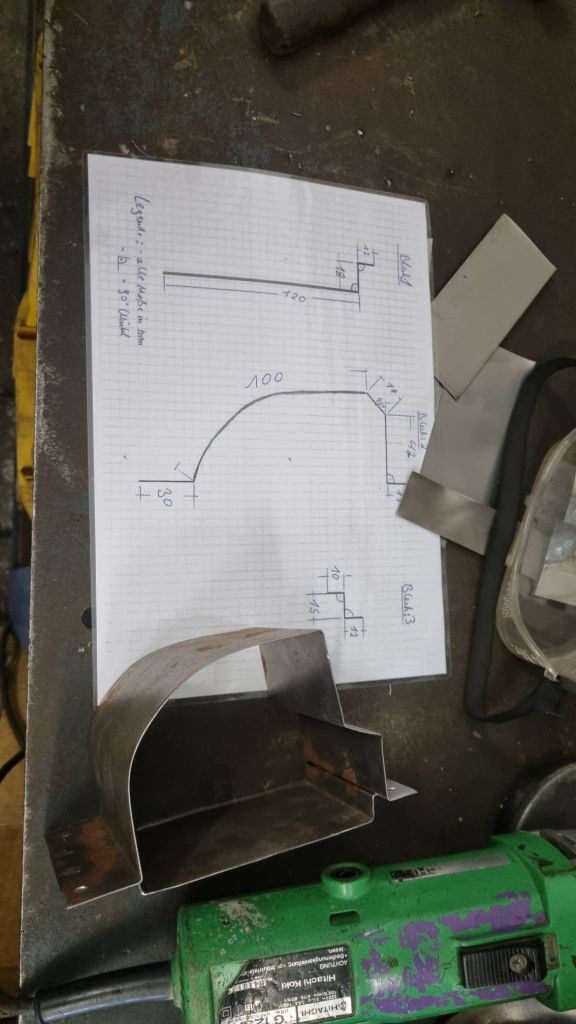

The task for the afternoon was a fabricate a sill piece – well, at least a very small one. Measuring, cutting, bending and figuring out where to punch, which edge to set back and so on, took a bit of time. Uwe shared many thoughts on how to best protect against rust. He also made noted that cars treated with the often citied Mike Sanders cavity sealing fat can be a mightmare to weld. Cleaning with Silicon remover and a second person to watch out for fire are essential here. Fluid film and some wax variants are much easier in this respect and offer similar protection.

Last exercise for the day was to butt weld two sill pieces together. This turned out to be quite challenging. It is all too easy to burn holes into the thin metal edge. Initially, I thought that just doing spots and trying to distribute the heat is a good idea. But once you have a hole, I found it easier to set spot after spot quickly – basically in the hot weld of the previous spot. This cause the lower part of the sill to distord slightly. It was my first attempt and not the best result – but it is a start.

Will the course help me to weld up Mildred (or Maggie’s sills) all by myself? Certianly, not. But I can imagine welding in some of the repair panels. The floors can to my mind – I believe these should be doable. But a major obstacle is the required equipment. Sure, a welding machine is affordable, but there are many other tools also required. Need to think about this a bit.

Wow now that looks like real fun well done!

LikeLiked by 1 person