Finally! It took much longer than expected to get the parts of Mildred’s engine back. The first part of the engine rebuild was the disassembly back in February 2024. The company I worked with sent the parts to an external machine shop in Aachen. Expected completion was about 6-8 weeks. Calls in April, May and June to get at least a status update were left unanswered. On June 24th I got a WhatsApp message that I need to have patience – the machine shop is too busy. Five weeks pass without news. By the end of July I visited them with my MGB GT – and get the promise that I will get an update in August. But after this all call attempts to the office phone number were left unanswered. On Sep 20th I tried a WhatsApp message, which finally led to reply on Sep 23rd.

The message was that the office phone cannot be answered during the day. Not sure why a call-back is not possible when you see the number in the caller list nowadays. It is also interesting that other customers I know had no issue calling the office number during the day. But the second and better part of the message was that an update from the machine shop will be requested and follow shortly.

Another two weeks pass without update. My call attempts and WhatsApp requests to get a call-back are ignored. Obviously, by this time I was not sure anymore if they really want to do my engine rebuild with them. I mention this concern to somebody via email. Three days later on Oct 24th, I finally get a positive WhatsApp message. Engine parts are being worked on and should be completed by week 45 (Nov 3rd to 9th)- the beginning of Nov. We ended the WhatsApp chat with a smiley – I thought all is good now.

Time passes – no proactive message from the workshop. On Nov 11th (week 46) I sent a short WhatsApp with the question if the pickup from the machine-shop has worked out. No reply. My phone calls – all ignored again. As customer I find it rather strange not to be able to get any usable feedback on the status of a project. On Nov23rd after consulting two other MG friends on what I should do – I decided to pickup the parts still in storage with the workshop in Cologne. It was now clear that I will end the engine rebuild project with this company. This looked like the logical step as normal communication with the owner was no longer possible.

When I arrived in Cologne and calmly explained that I would like to pick up my parts – the owner got loud and very unfriendly. My call attempts (on an official office phone number) were seen as harassment. I was told that I should be able to see that he has too many other more important projects in his workshop. My engine would just need to wait. I calmly requested to get my parts back in this case. That should have been in his interest also – if there was too much work anyway. If the machine shop finished my part – great, then getting them back should not be an issue. If the machine shop did not work on them – also not an issue, I would pick them up and look for a different place.

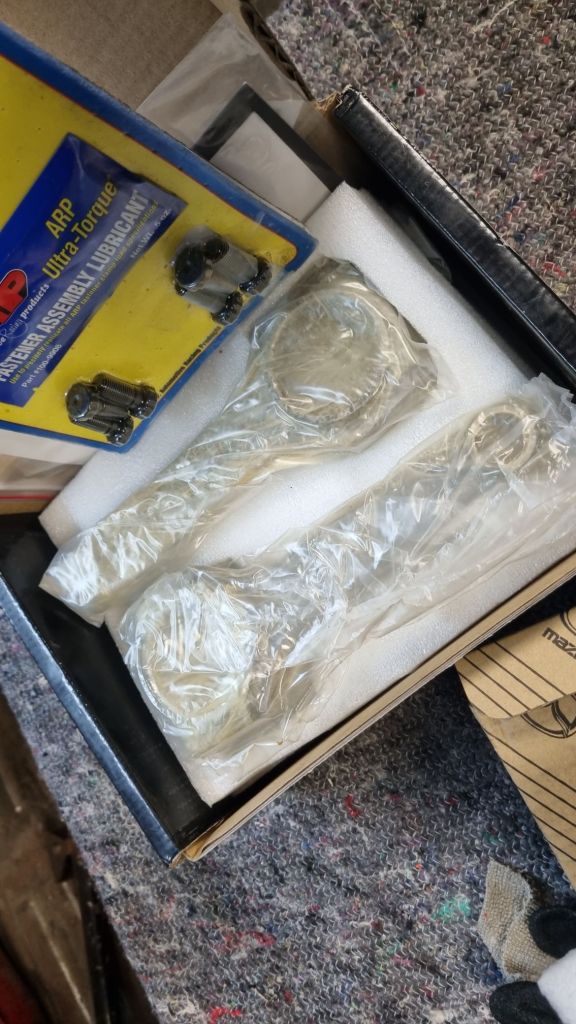

Today – almost an entire month later – I finally get an invoice and the message that I can pickup my engine parts. The charge for the disassembly and the machine shop is 1802€ (plus VAT). Higher than expected – but by now I just wanted to get my parts back. The block is bored out +0.060″ and resurfaced. One thing I am unsure about it the amount of rust in the in the water channels. At least in comparison to an 18GB block (which I just saw at a different machine shop – my freshly returned block does not as good. The plugs of the oil galleries should also have been opened and cleaned….

According to the invoice the crankshaft bearing journals were polished, nitrided (hardened), aligned and balanced. What I would have expected is the information with main and conrod bearing size I now need. When I asked I was told I will get this via email. The last line about the external works on the invoice say that the crankshaft has been balanced with the flywheel, pulley and mounted clutch. Well, it is close to magic in this case that the clutch is exactly wrapped like it was when I bought it. The Fidanza flywheel has not a single indication that the clutch was bolted to it. The new uprated Pulley not even a finger print on it.

All in all – this was a very disappointing experience. I certainly cannot recommend this workshop for GreatBritish Classic cars in Cologne Porz to anyone anymore. My plan to test drive the 18V engine with the Mazda 5-speed gearbox in Maggie this year failed. It would have given me the chance to overhaul Maggie’s Ford T9 gearbox. The 18V engine and drivetrain could have been tuned-in properly – reducing issues on this front when completing the rest of Mildred. But then again – maybe I still do this in 2025. The bodyshell is also not even close to being finished. Some more infos on this will follow in January.

Alright, enough looking back – what’s next now? After the holidays another machine shop will double-check the block and crank. It might be that everything is OK – but communication with the workshop in Cologne has been such a bad experience – I don’t have any trust in them anymore. Maybe they surprise me with the promised email on the bearing sizes. Once I have this confirmation, the right ACL tri-metal bearings can be ordered.

And who knows – maybe the change is better in the end. Michael – a fellow MGB GT driver from Belgium – already built a few performance engines. His car ran amazingly during the BritishOdyssey. He offered that we can do the assembly of my engine together next year. I am really looking forward to this.

Ugh! I’m so sorry to hear stories like this. It’s a rare combination that finds good business sense and practices under the same roof as mechanical skill and knowledge. You usually find one, the other, or neither.

Best of luck with the new engine builder.

LikeLike

True. I am utterly surprised about the way this went down. Just because i tried to get information about where things stand.

I am sure the workshop can deliver good work – but if customer calls get left unanswered and are seen as harassment – I guess external help would be advisable

LikeLiked by 1 person

Goodness what a sad story. Phone calls are harassment? Crazy.

LikeLike