UPDATE Jan 21st 2026: The 3MF file for this part is now available on Makerworld.

https://makerworld.com/de/@fixingC6622

Even after 60 years most MGB spare parts are relatively easy to find. There are a few exceptions however. And the Buffer and Catch for the earlier metal dashboards is one of them. None of the stores I looked at – eg. Rimmerbros, Moss or Angloparts will list them as available. Occasionally used parts pop up on Ebay.co.uk – with prices ranging between 25GBP up to 50GBP. Mildred’s dashboard only had the catch (somewhat rusted) – the buffer disintegrated as some point. The two LHD dashboards I bought for the conversion also both came without the catch and the buffer – as do most of the dashboards offered on Ebay or at part swaps/markets – like the one in Stoneleigh park.

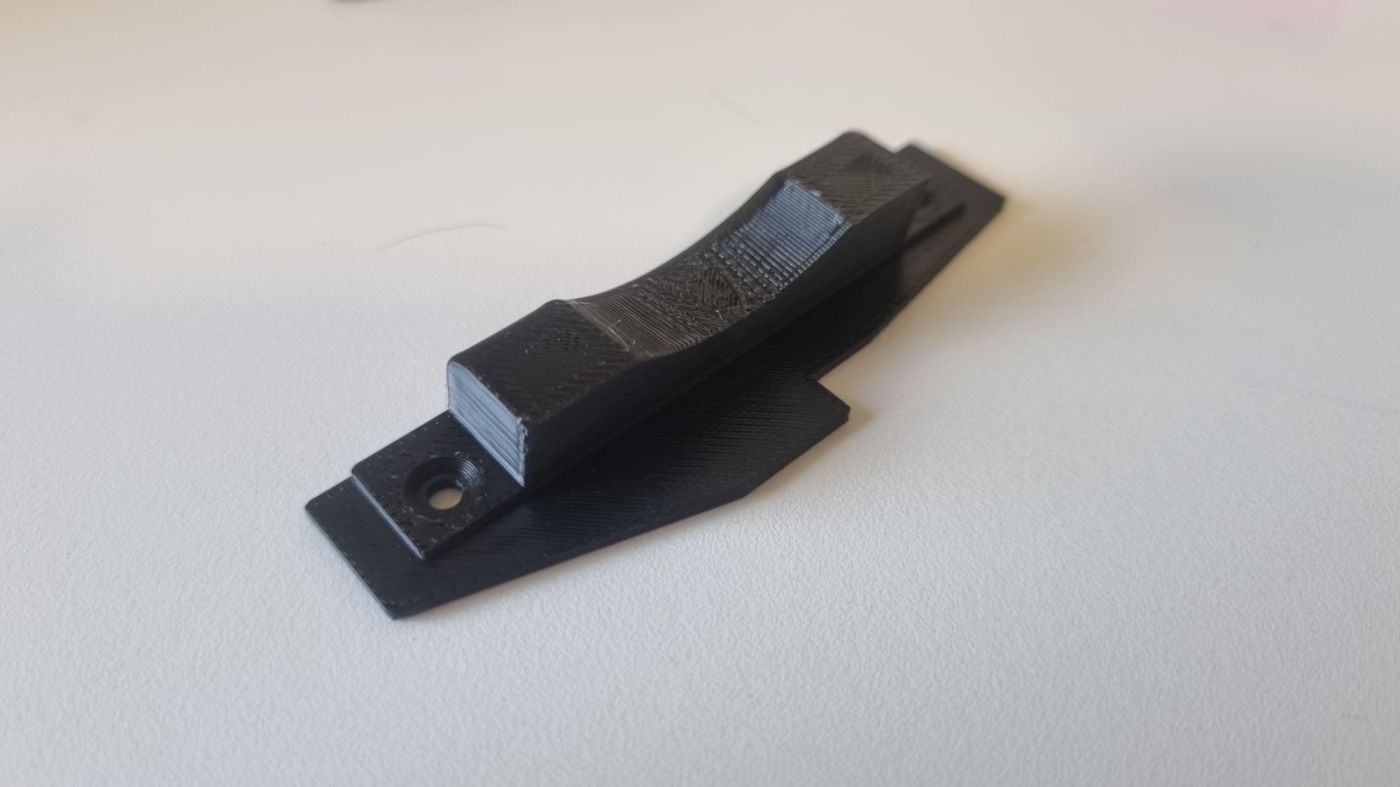

Last year I asked my son if he could 3D print for me – but instead I got the 3D printer at Xmas, which is basically as saying: Dad, you can figure this out yourself. So I did. Figuring out the basic shape in Freecad was fairly easy. I started with the catch, which I initially considered cutting out of a piece of sheet metal. After that the buffer was also measured and sketched. Basically it is just a slightly backward angled cuboid with a cylinderical indent in the middle. The orginial buffer is a 1mm thick piece of metal that has a bend back part. My guess is that the original rubber was bond to this through vulcanization. Reproducing this would be somewhat of a challenge – especially if you only need a few of those – but printing it is easy.

TPU is a rubber material that can be printed. It comes in different shore hardnesses that are represented by a number. The higher the number, the stiffer/harder the material. For the MGB buffer TPU 95A from Bambu seems to be close to the original one. But instead of gluing the rubber part to a piece of sheet metal – I decided to print both parts in one go with two different materials. The catch and lower part of the buffer are printed in PETG (ABS or ASA would also work). I then spend some time digging into more options with the slicer – in the end I followed this great guide on Youtube. Due to a small mistake in FreeCad my object configuration was not perfect – but once I understood the concept I worked with a height modifier and a pause for the filament change.

The result is a combined catch & buffer design with a strong PETG plate and TPU as rubber buffer. Dimensions are currently exactly like the orginial. Another benefit of this approach is that I can now slightly modify the buffer pitch and depth – allowing adjustment of the glovebox lid for better alignment. If somebody is interested in the print files or needs a reproduction buffer – let me know. I am fine with sharing it as long it is not used commercially. (might make it available on the Bambu MakerSpace)

Well done!

LikeLiked by 1 person

Hi Tim, Can I use this article in your MG Newsletter the Dashpot plus a couple others I have read?

LikeLike

Hi Tim, can I use this plus a couple other of your articles in the Ottawa MG Club’s Newsletter the Dashpot?

LikeLike

Thanks for asking. Yes please do

LikeLike

Hi Tim, we could really use one of these for the restoration of my 1974 MGB roadster, happy to cover costs if you could provide one.

ThanksJeremy

LikeLike

Hi Jeremy. Depending on where you live it might be easier to have the part printed close by instead of sending it via mail.

I am currently travelling – will share the link to Bambu Makerlab next week.

LikeLike

Thank you Tim, I’m in Bedfordshire UK

LikeLike

Hi Jeremy.

It took me a bit to get familiar with the process – but I finally managed to upload my first project to MakerWorld.

https://makerworld.com/de/models/1529509-mgb-glovebox-catch-ahh6291-and-ahh6292#profileId-1603845

This is the combined print with manual material change after about 10 layers. The print should automatically pause and request to switch from PETG to TPU.

I will also upload the two individual parts in case you want to craft the catch out of metal and just print the buffer in TPU.

Hope this works for you.

Regards

Tim

LikeLike

Hi TimBThis doesn’t seem to be on makerworld anymore TimS

LikeLike

Thank you for pointing this out. I have updated the link

https://makerworld.com/de/@fixingC6622

LikeLiked by 1 person

Awesome TimB – thank you !

LikeLike